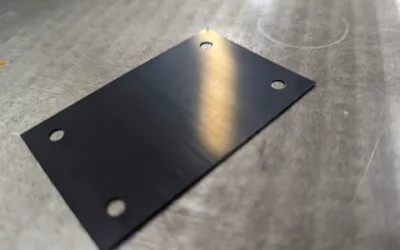

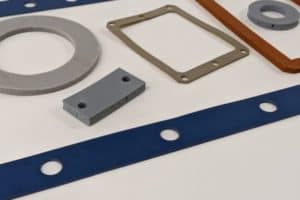

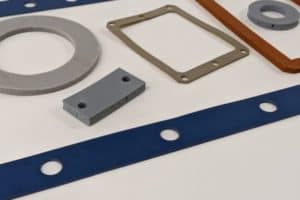

Custom Gaskets

Fluid/Fuel Resistant, Fungus Resistant, Temperature Resistant, Air Sealing Gaskets, and others

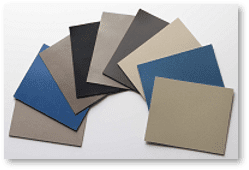

assortment of custom gaskets

Custom Gaskets are NEDCs main product. We manufacture different types of all different environments, and industries.

What are Gaskets?

What Are The Questions to Ask When Choosing a Gasket Material?

Function/Requirements

Gaskets can be subject to a number of different environmental concerns/stresses. There can be quite a few potential concerns when choosing a gasket.

-Whether the gasket will be subject to fluids such as oil, fuel, brake-fluid, or other fluids?

-If the gaskets will do a lot of temperature cycling from low temperatures to high temperatures, or possibility a variety of both?

-How much compression the gasket will be subject to?

-Whether the gasket will be exposed to ozone, and UV?

-EMI/RFI shielding requirements of the gaskets, or if the gasket needs to be conductive, antistatic?

-Whether the gasket will require an adhesive backing?

These questions lead into what selections are available out in the industry for solutions. At NEDC, we are familiar with many of the selections available.

Polymers/Availability for Custom Gaskets

Availability usually comes down to the same questions as above to start boiling down the potential solutions.

There are:

-High Temperature, and Low Temperature Gaskets -Flame Retardant Gaskets

-UV Resistant Gaskets -Fuel Resistant Gaskets

-Low Compression Set Gaskets -Ozone Resistant Gaskets

-Soft/Hard Gaskets -Electrically Conductive Gaskets

Materials/Composites Available

The above types of gaskets are made up of a combination of different types of polymers/composites/rubbers. Many of these materials can be provided in cellular form such as sponge or foam rubber materials. These selections include:

-Viton Rubber(Fluoroelastomer) FKM -Fluorosilicone Rubber (FVMQ)

-Urethane Rubber -Nitrile Rubber

-SBR Rubber -Epichlorohydrin Rubber

And more

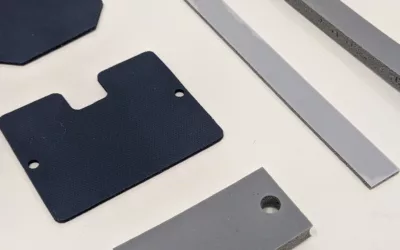

custom dust gasket

custom dust gasket

Types of Gaskets Available?

With all of these different types of gasketing materials, and quesitons- what kind of custom gaskets are produced?

-Dust Gaskets -High Heat Gaskets(Heat Resistant Gaskets) -Thermal Gaskets – Food Grade Gaskets – RFI/EMI Gaskets – Canister Gaskets – Furnace Gaskets – Plenum Gaskets – Electrical Outlet Gaskets – Flange Gaskets – Speaker Gaskets – Outdoor Light Fixture Gaskets – Transformer Gaskets – Vacuum Gaskets – Recessed Lighting Gaskets – Air Compressor Gaskets – Solar Panel Gaskets- Speaker Baffle Gaskets

more custom gaskets

more custom gaskets

More Availability of Custom Gaskets

The availability goes one step further with all of the different solutions that branch out. There are plastic gaskets, sponge/foam gaskets, and VHB Tape Gaskets.

VHB Tape Gaskets

VHB Gaskets refer to VHB Tape materials provided by 3M cut into shapes that offer gasketing solutions. They are used in place of permanent fasteners. The time saved in assembly and processing can be dramatically cut down with VHB. The reason these acrylic foam tapes are used is because they offer great permanent bonding strength. In addition, they can seal out many mediums such as dust or water when properly applied. These tapes are commonly used on computer like tablets. These acrylic foam tapes include ultra thin and thick options to accommodate different applications. There are countless families of VHB Tapes to chose from. The main VHB Tape families are 4941, 5952, and RP Tapes. However, there are quite an assortment of options, including high temperature options, low temperature options, powder coated surface adhering options, and more.

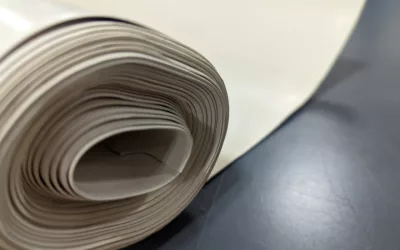

Sponge/Foam Gaskets

Sponge/foam gaskets include cellular products that allow for less compression force. It is normally required to have significant pressure to seal out different medias properly. These materials have been chemically, or otherwise expanded. However, they are commonly made out of the same base materials as many solid rubber gasketing options. Some examples of foam/sponge gaskets include silicone sponge, fluorosilicone sponge, neoprene sponge, PORON®(urethane foam), or sponge blends. Sponge and foam gaskets are highly customizable. Some examples of that include thermally conductive options, electrically conductive options, and ultra-soft/firm options.

Commonly known cellular foam/sponge products include:

–Silicone Sponge Products such as NORSEAL® R10400, R10450, R10460, R10470, R10480, and R10490 by Saint Gobain Performance Plastics.

-PORON® Urethane Foams by Rogers Corporation. PORON® has a huge variety of thicknesses, densities, and firmnesses available for purchase.

–Silicone Foam Products such as BISCO® HT-800, HT-820, HT-840, and HT-870 by Rogers Corporation.

-Electrically Conductive Products such as Condux Plus™ from Rogers.

-Thermally Conductive Products such as Thermacool R10404 from Saint Gobain.

Plastic Gaskets

There are times that gaskets are made out of plastic materials instead of elastomeric ones. Some materials used include PTFE(Teflon), Nylon, UHMW, G10 Epoxyglass, and more. These materials are cut out of flat sheet materials by NEDC. As a result, the plastic we cut is usually relatively thin due to the fact we are cutting through it with either a die, laser, or a water stream.

Gasketing for UL Rated Applications

For applications that require a UL listed material- there are many options to chose from. Many of the big manufacturers/OEMs have sent out their products to become UL listed for either sealing(UL 157), flame retardancy(UL 94), or safety in control panels(UL508)

Tape Backings(Pressure Sensitive Adhesive)

With custom gaskets tape backings are available. These help with assembly. Many different types of peel and stick options are available. Oftentimes NEDC will apply acrylic pressure sensitive tape such as 3M 9472, or 9485PC. These high-performance acrylics stick well to most high-surface energy substrates. However, silicone pressure sensitive adhesive options are also available.

Thickness Tolerancing for Sheeted Goods for Gasket Products

Gaskets are meant to be compressed. Sponge/Foam Gasketing materials compress more with less pressure then their solid rubber gasketing material counterparts. When adding a material to a print- the thickness tolerance can come from a few different places.

-The Print has a thickness tolerance demanding by the application- oftentimes this ends up being more stringent than is available commercially, easily.

-The Specification associated with the material. For example, AMS-3195, a silicone sponge specification has thickness tolerancing associated with it.

-If no tolerance is specified- its usually assumed that RMA tolerances apply. Below we have added a table of RMA thickness tolerances for sponge/rubber.

About NEDC

NEDC is a die-cutting manfacturer, and supplier of various cut products that utilizes waterjet cutting, laser cutting, and die-cutting to cut the above listed materials into custom gaskets. If you have an application that you believe could utilize a custom manufactured gasket, please contact sales@nedc.com.

BISCO® & PORON® are registered Trademarks of Rogers Corporation.

NORSEAL® is a registered Trademark of Saint Gobain Performance Plastics.

Gaskets Blog

HPMS Graphite | Flexible Graphite | Custom Die-Cut Parts

At NEDC, we like to think we are experts in thermal interface materials. Flexible graphite material is an excellent thermally conductive material. In fact, I see a lot of thermal interface pads going in this direction due to its great thermal conductivity, & low...

Previous Posts

T-Global Technology | Thermal Gap Pads | Thick, Thin, High W/m-K

At NEDC, thermal pads are our specialty. Our manufacturing site is in...

EMI/RFI Bulb/Hollow Gaskets – The Softest EMI/RFI Gasket

At NEDC, we mostly die-cut, knife-cut, or waterjet cut gaskets. However,...

Low Durometer/Soft EMI/RFI Gaskets – 30A, 40A, 50A Gasketing

For years, NEDC has supplied low durometer gasketing materials to...

R10400M (Medium) Flame Retardant Silicone Sponge | Custom Die-Cut Parts

Silicone Sponge, and Silicone Foam are different. I’ve talked about that in another blog on our website. Both have desirable properties. Some have good physical properties, and some have good flame retardant properties. There are some products that can actually be...

Thermal Pad vs. Thermal Grease/Mica

One common question I hear engineers ask about is if it's better to have Mica/Grease or Sil-Pad products. Obviously, I’m partial to this, but I wanted to give some thoughts I had about Mica/Grease, and why I think it has its place, but why I think in a manufacturing...

IP Ratings – Gaskets & Ratings | Particles/Liquid Ingress

IP (Ingress Protection or International Protection) ratings are a common way to define how protected an electrical enclosure is from foreign matter that does not belong in the said enclosure. Gaskets are frequently used to provide the protection set forth in this...

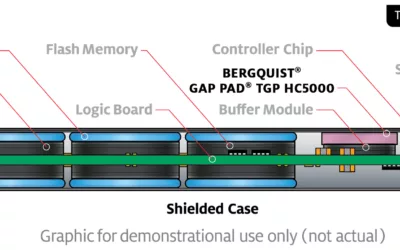

Thermal Interface Pads/Liquids for Solid State Drives(SSDs)

As the industry moves from hard-drives(HDDs) to solid-state drives(SSDs). SSDs offer significant advantages over their hard drive counterparts. However, since SSDs operate through an electrical current, they still get hot- just like every electronic. Heat continues to...

TFLEX 600 | High-Compliance Thermal Pads | Low-Stress

NEDC manufactures thermal pads for many different customers. The thing I love about thermal pads, there is so many of them. Each one has different properties, and has its own fit for applications. Properties of TFLEX 600 Thermal Pad TFLEX 600 is a boron nitride...

Passivated Silver Aluminum EMI Gaskets | Custom Cut Gasket

NEDC manufactures gaskets of all sorts. Our arena of play in the gasket world usually is high value gasketing materials. For that reason, a lot of the build to print items we see include “SILVER FILLED” or “SILVER - COPPED FILLED” A question we get very often, is...

Silicone Foam Challenges, and Silicone Foam Alternatives

Over the past two years, silicone foam has become a particularly challenged material when it comes to lead times. As of this writing, there has been cases where we have waited a year for some silicone foam. Although, it is true, lead times have improved dramatically...

Engineering Note: Hole Diameters: How low can you go?

At NEDC, cutting gaskets is what we do. Gaskets typically have holes in them to provide room for screws or bolts to go through them in order to provide pressure, and then for that reason, also to provide compression for the gasket to seat/seal properly. How small is...

Liners for Die-Cutting – Why is there Thick, or Thin Liners?

NEDC is an authorized converter for 3M company. For that reason, we often get questions from customers about the adhesive tape products we offer. Customers often ask, what is the difference between this tape, and this tape? The reason customers ask this question, is a...

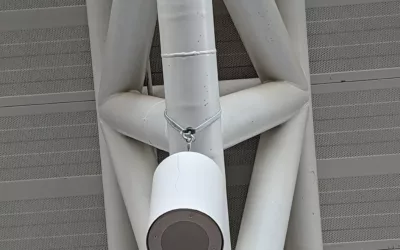

Application Note for Speaker Gasket Found In Airport

When people ask me what I do for a living, I'll be honest- I struggle trying to tell them what I do. I usually end up just saying, most of the parts we make are for aerospace/military applications. Which is true. However, frankly that is a terrible answer. I'm going...

Tips/Tricks to Avoid Supply Chain Disruptions | Custom Die-Cutters

In this supply chain taxed environment, I thought I’d write a blog about how to keep your supply chain moving at the maximum speed possible- whatever that may be nowadays. In this blog, we will provide some tips, and tricks to keep your supply chain moving....

FDA, 21 CFR 177.2600 Gasketing Materials | Neoprene, Nitrile, FKM, EPDM

About 8 years ago, when I had first started blog writing- oh God, don’t remind me it was 8 years ago, I wrote a blog on FDA Gaskets for silicone rubber products. This blog only covered what was available for silicone rubber products. In that blog, we neglected rubber...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

Can you use a Thermal Pad/Gap Pad more than Once?

My blogs largely originated from the various questions I have gotten from customers over the years. This includes the most popular ones. One question I realized I get an awful lot is : “Are Gap Pads Reusable?” Heres my short answer, “It depends, but I wouldn’t ever”....

Die-Cutting vs Laser Cutting, Epoxy Preforms: Part 2

I had a customer call the other day, saying he heard that laser cutting was better than die-cutting for frozen epoxy preforms. Heres the thought I had in my head “Why does this keep coming up!?” Heres my thought, and then I’m going dive into every advantage, and...

Super-Soft Silicone Rubber Gaskets | Tight-Tolerance/High-Temperature

At NEDC, Custom Silicone Rubber Gaskets are a common product we sell. Included in that category are the Super-Soft Silicone Rubber Gaskets that are available. When I think soft gaskets, typically below 40A durometer would be considered soft. However, when I think of...