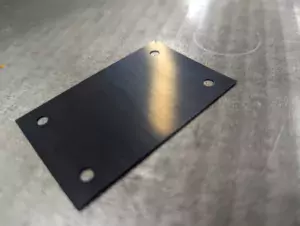

holes cut

At NEDC, cutting gaskets is what we do. Gaskets typically have holes in them to provide room for screws or bolts to go through them in order to provide pressure, and then for that reason, also to provide compression for the gasket to seat/seal properly.

How small is too small?

Our customers will ask all the time. How small of a diameter is too small? You all are going to hate me for this explanation. However, the answer is.. It depends. Ok, well if I can get away with that answer.. I have to have a follow up with some explanation.

Well, what are the factors?

What does it depend on? Several factors.All three of these factors often come together to provide the answer of how low you can go.

- Thickness of the material

- Sturdiness of the material/ability of the material to deflect

- Proximity of those/that hole to other shapes/cutouts/walls

Factors

Lets start with the first one: Thickness of the material.

When I first started here, the rule of thumb was “the hole should be the thickness of the material” – which I generally agree with, but frankly I don’t like that rule because you can actually get away with a lot more than that sometimes. It depends on the other two variables mentioned above. Thinner materials often can withstand smaller holes. However, I will say, I’ve seen materials that are too thin collapse holes for that reason as well, so it sort of goes both ways.

Sturdiness of the Material

A sturdy material can withstand a smaller hole diameter, this is because, the material doesn’t deflect away from usually what is a waterjet stream.. Or a punched hole, and collapse into something else. This can really be a problem with foam, or sponge products. For example, a solid rubber gasket might be able to withstand a .035’’ hole, well a silicone sponge gasket may only be able to withstand a .045’’ hole.

Proximity of the hole to another hole

This is where the conversations of “walls” comes in. The closer a hole is to a “wall” of another cutout, or the edge of the part, the more likely the hole is to blow out. When placing holes next to the edge of the part, or another cut-out, a good rule of thumb is .050’’ or more. However, again, more or less might work/not work depending on the other two factors above.

More Information

For more information on die cutting gaskets, or you believe you have an application that could utilize a gasket please contact sales@nedc.com.