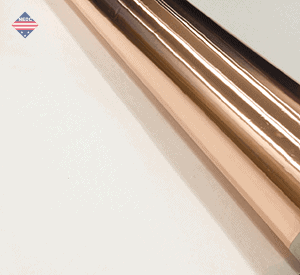

3M Copper Foil Tape 1181

At NEDC, we work with many materials that are used for EMI/RFI shielding, including gaskets, seals, and extrusions. While gaskets are our core product line, we also provide the value added benefit of converting 3M Copper Foil Tapes. 3M provides various different foil tapes, but this blog will cover one of the more common types NEDC works with: Copper Foil.

Uses/Properties of Copper Foil Tape

In a world that is becoming more focused on electronics by the hour, 3M provides a copper tape that can provide great shielding effectiveness, and conductivity. These tapes are used to reflect, attenuate, and block signals coming from the outside environment. Not only do they attenuate signals from the outside, they can also provide shielding from other components inside the assembly. These tapes have been used for a number of shielding applications, including shielded rooms, enclosures, reduction in electrostatic coupling, and other grounding applications, while providing an effective, and economical means to do this. In addition, the tapes have a reliable way to remove dangerous static charges through high conductivity. Most of 3M’s Copper Foil Tapes are provided with an electrically conductive adhesive to ensure complete electrical contact even through/at the bond area.

Types/Adhesives Available

There are many constructions of foil tape available. Some foil tapes have an embossed pattern, such as 3M1245. This embossed pattern is important because it is able to penetrate spots in the adhesive, conductive or nonconductive, to provide an electrical contact. 3M Copper Foil Tapes are provided with acrylic adhesives that can provide high strength bonding to high surface energy substrates such as aluminum or steel, substrates typical in electrical enclosures. These tapes can also show resistance to temperature, and aging. There are times that it is necessary to stick the copper foil to two different substrates simultaneously, and in cases such as these the 3M1182 Copper Foil may come in handy. This tape is equipped with conductive acrylic adhesive on both sides of the foil, providing strong adhesion on both sides. The only copper foil without electrically conductive adhesive is 3M1194. However, all of the copper foil backings maintain a low resistivity to ensure high conductivity. All of these tapes are UL-recognized under UL 510 for flame retardancy. Other 3M Copper Foil Tapes include:

More Information/Cutting

As an authorized 3M converter, NEDC can supply diecut parts or rolls. These tapes can also be provided on a liner for ease of removal by being “kisscut” which can be provided with, or without the copper foil webbing still intact. For more information on 3M Copper Foil Tapes please contact sales@nedc.com.

Other Datasheet Downloads