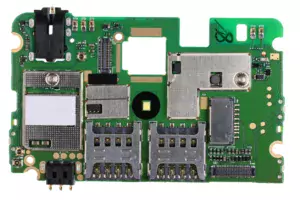

Circuit Board, needs new Thermal Pad

My blogs largely originated from the various questions I have gotten from customers over the years. This includes the most popular ones.

One question I realized I get an awful lot is : “Are Gap Pads Reusable?” Heres my short answer, “It depends, but I wouldn’t ever”. In certain contexts you see below, you might be able to argue the pad is still usable- it’s your application, do what you want. But I wouldn’t.

Why Not to Reuse Thermal Gap Pads?

- I suggest most of my customers get a minimum of 10% compression, and a maximum of 60%, and I’ve seen customers do a heck of a lot more. If you think that the Gap Pad is going to recover from that, good luck to you. I’ve seen pads take a permanent set of 100%, meaning if it’s compressed 30%, that 30% is gone for good. You don’t get any of it back

- While most pads don’t dry out- the initial thermal tack with contact actually plays a pivotal role in the thermal transfer of heat. That being said, I’d be concerned that the factory natural tack wears down a little bit, allowing less thermal performance.

- Lets say there’s a 95% chance the pad is going to work fine reusing it- You have to ask yourself, this pad is essentially an insurance policy against your electronic device overheating, losing overall life, or worse complete failure- so my thought process is, you bought an insurance policy- its best to keep the premiums current. When something catastophric happens, it wouldn’t be enjoyable to learn its not covered because you didn’t pay the preminums.

Afternote:

I get a lot of customers asking us to recert thermal pads. Again, some pads would probably be fine, but NO I AM NOT GOING TO RECERT ANYTHING. Don’t ask me to, because its not going happen. But heres a few things to think about:

- Does the liner remove cleanly? Conversely, if a liner is not supposed to be removed, does it offer the same stiffness, or is delaminating?

- Is the thermal performance the same since you bought it? (this includes natural tack, pad stifness/hardness, modulus.

More Information

NEDC die-cuts, knife-cuts, and waterjet-cuts thermal interface pads into custom shapes, and sizes for customers. For more information on Thermal Gap Pad materials, please contact sales@nedc.com.