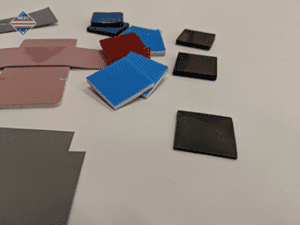

Assortment of different thermal pads

Cost

The first thing to consider is that normally the higher thermal conductivity, the more you are going to pay per pad. Naturally, the more conductivity you get, the more filled the pad is with thermally conductive fillers that may increase the cost of the pad. While this is not always the case, oftentimes it is. If you’re truly paying for higher performance, this may be worth it, but many times this may not be the case.

Performance

The second thing to consider is that while the thermal conductivity of one pad over another may be higher or lower, that does not mean a whole lot on its own. It simply gives you an indication of how it may perform. Since there a number of metrics on any given datasheet, they should all be used to paint a larger picture. These include but are not limited to hardness, density, thermal impedance, and modulus. For example, if the the softness is not compliant enough, the assembly may never be able to take advantage of the thermal conductivity because it will not wet out onto the surfaces. Other information that may be included in datasheets that can be very helpful include dielectric performance and charts showing thickness vs. thermal resistance.

Testing Methods

An important thing to understand is that there really are not any industry standard methods used by all companies to rate the thermal performance of a given pad. Oftentimes the measurements of thermal conductivity could be made under different conditions. If one person tests thermal conductivity one way and another tests it differently, then they are not the same. It is very important to understand the test methods used by a company when they list properties of a given pad. One commonly-used testing method for thermal conductivity is ASTM D5470. Be sure to understand the test methods used when comparing thermal pads. This is why it is so important to test a thermal pad before use in an application.

NEDC commonly die-cuts and waterjet cuts different thermal pads for many different industries. For more information on some of the thermal management solutions NEDC cuts into shape please contact sales@nedc.com.