Electrical Insulators

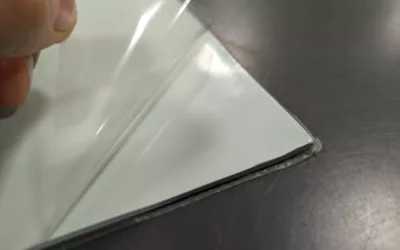

Kapton Insulator

Die-Cut Insulators were one of NEDC first products. This product line went along with gaskets as some of the first parts NEDC cut for customers. When NEDC first started, most electrical insulators were die-cut. However, with the new machinery that NEDC employees, waterjet, laser, and other machines also play a part.

Materials

Many of the materials used for electrical insulation are also used on our other products. In other words, gaskets, and thermal pads may also isolate an electrical current. As a result, materials including plastic, thermal interface pads, rubber, and paper like products all may have the ability to be electrically isolating.

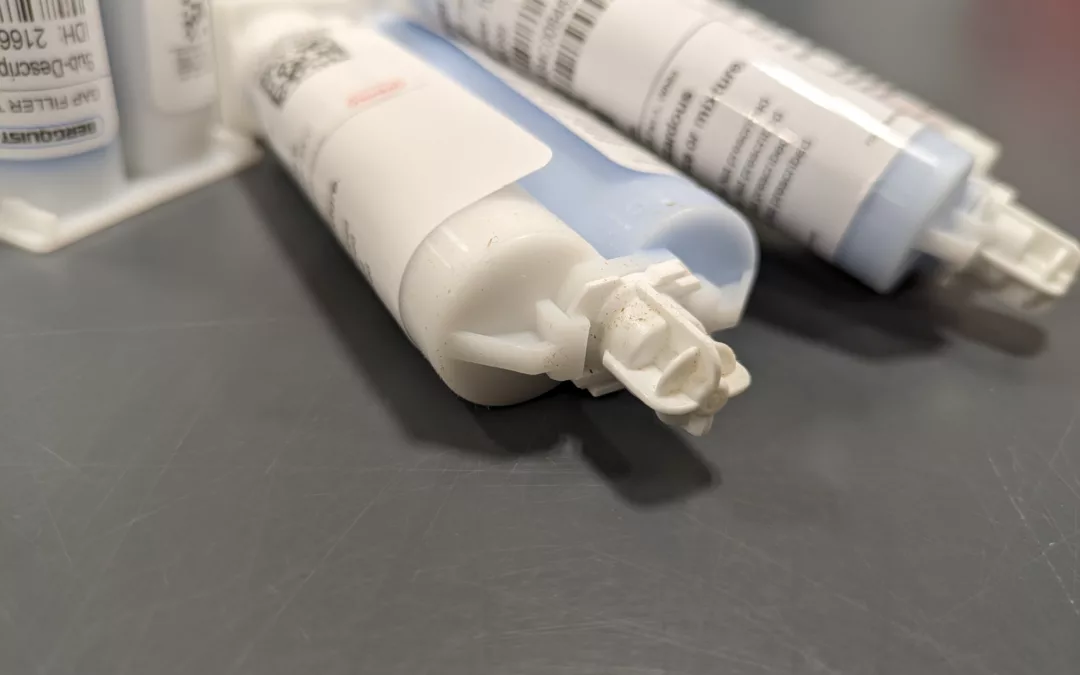

Thermal Pads

One of NEDCs core products are thermal pads. For that reason, its interesting that thermal pads oftentimes serve as electrical insulators. Products such as Sil Pad®, and Gap Pad®, are marketed because of their high volume resistivity making them ideal for electrical insulation while providing a thermal management solution.

Many Gap Pad® products offer electrically insulating properties. Gap Pad® products such as GPVOUS, GPVOS, GP5000S35, GPHC3.0, GPHC5.0 offer high levels of electrical insulating properties. This is in addition to their thermally conductive properties as well.

Many Sil-Pad® products offer electrically insulating properties. Sil Pad® products that are electrically isolating include Sil-Pad 900S, Sil-Pad 2000, Sil-Pad 400, and others.

Thin Plastics

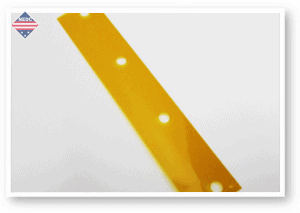

Many thin plastics that NEDC cuts are electrical insulators. Materials like Kapton®, Mylar®, Lexan®, Formex®, G10/FR4 Epoxyglass all may serve as electrical insulators. These plastics can be converted into die-cut insulators.

Mylar® is a polyethylene terephthalate(PET) that is registered by DuPont. These materials usually come in thin films ranging from .002” to .014” in thickness. It is commonly used as an electrical insulator. MYLAR® A is the most common type. Mylar® MO is approved for Class B insulation.

Kapton® is a polyimide film that is registered by DuPont. This plastic can be certified to MIL-P-46112 Type 1, and ASTM D5213 Type 1 Item A. It usually comes in thin formats such as .0005” to .005” in thickness. Anything above this enters into the category of Cirlex®. Common applications include insulation blankets, and insulation tubing. There are a few different types of Kapton Film besides Kapton HN. These include Kapton® FN, Kapton® FWR, Kapton® GS, Kapton® MT+, and Kapton® RS.

Lexan® is a polycarbonate plastic that is oftentimes die-cut in film form. Lexan® plastic is a registered trademark by SABIC. Lexan® is extremely tough, but is formable. There are many different types. However, NEDC mainly die-cuts 8010, FR700, and others.

Formex® is a flame retardant polyproylene plastic. Formex® has excellent electrical properties. This plastic is fungus inert. There is GK-5, GK-10, GK-17, GK-30, GK-40, and GK-62. These plastics run from .005” in thickness to .062”.

Epoxyglass/G10/FR4 is a plastic like material that is really laminated glass with epoxy bonding it together. These materials are oftentimes used as electrical insulators. Most often NEDC die-cuts these materials, the thickness is below .015”. G10 is generally not thought of flame retardant. However, FR4 is flame retardant. MIL-I-24768 encompasses many different options. G10 being /2, and FR4 being /27. These materials are generally available .005”-many inches thick.

Rubber

At NEDC we cut many rubber materials to make gaskets. However, rubber materials can also sometimes serve as electrical insulators. For example, silicone rubber is a great electrical insulator that is commonly used in cables or wiring. Some other rubber materials used for electrical insulation include fluorosilicone, neoprene, EPDM, or urethane.

Silicone Rubber is commonly used as an electrical insulator. In fact, this material is probably the most commonly used material at NEDC. We use silicone rubber for gaskets, insulators, vibration dampening, and many other uses. Common certifications include A-A-59588, ZZR765, and others.

Fluorosilicone Rubber is another commonly used electrical insulator. However, it is not as commonly used as silicone because of its other qualities that tend to make it more expensive. Some specifications include MIL-R-25988, AMS-3329, and others.

Neoprene Rubber is a synthetic rubber also another commonly used electrical insulator. It is used in cable jacketing for wire and cable. It is often flame resistant.

Paper like Products – Die Cut Insulators

Many paper like products serve as electrical insulators. Some common ones that NEDC sees are Nomex®, Fishpaper, Kraft Pulp, and others.

Nomex® is a aramid fiber paper. It has a high dielectric strength. This paper is used for The most common type of Nomex® is Nomex 410. Nomex 410 comes in a number of thicknesses ranging from .002” to .030”.

Fishpaper is an electrically insulating paper that is resistant to heat. It is an excellent insulator used in fuse tubes, and electronic devices. Thicknesses of fishpaper range from thin (.005”) to thicker (.030”). Specifications include MIL-I-495. It mostly comes in dark colors such as gray, or dark blue.

Electrical Qualities to look for with Die-Cut Insulators

Volume Resistivity

Volume Resistvity plays a huge part in die-cut insulators. The higher this number the better. A low number indicates the materials conductivity. This number indicates how much the insulator resists electric currents.

Dielectric Strength

Dielectric Strength is an important metric with die-cut insulators. It helps determine the quality of the insulator. It is defined as the maximum voltage required to produce dielectric breakdown through the material. All the materials above would register a high dielectric strength, for example.

Thermal Pad, Silicone, g10, Sponge

Conclusion

As with most materials NEDC provides, adhesive backing is available on certain products. Some common tapes we use from 3M are acrylic based 9485PC, 9472, 467MP, and 9469PC. For more information on electrical insulators, or you believe you have a project that could use a die-cut insulator, please contact sales@nedc.com.

Electrical Insulators Blog

Thermal Gap Filler | NEDC distributes TGF 3600/GF3500S35 | Information

At NEDC, some say we are experts in thermal gap pads. We are also experts in liquid gap filler materials. So much in fact, we actually distribute both. One of the materials we like a lot, and will be highlighted in an upcoming video is TGF 3600, or...

Previous Posts

NEDC Launches Video Demonstrating How Thermal Pads Work!

<iframe width="1519" height="526"...

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of...

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for...

Thin Gasketing Options | .015”, & Below | High Performance Gaskets

Applications get smaller, and smaller everyday. As footprints of the electronics we serve get thinner, and lighter i.e electronic signs, tablets, and other peripherals, the gasketing must get thinner to accommodate it. We have customers come in all the time looking...

T-Global Technology | Thermal Gap Pads | Thick, Thin, High W/m-K

At NEDC, thermal pads are our specialty. Our manufacturing site is in Methuen, MA. Across the pond, in the United Kingdom, there is a reputable thermal pad manufacturer. This manufacturer is called T-Global Technology. They make a number of thermal interface...

EMI/RFI Bulb/Hollow Gaskets – The Softest EMI/RFI Gasket

At NEDC, we mostly die-cut, knife-cut, or waterjet cut gaskets. However, we do also fabricate, glue, or bond together some gaskets. Why do we do this? The short answer is because we cannot die cut, or waterjet cut them. However, sometimes it's also for performance...

Applications: Scanner, PDDs, Analyzers – Gaskets, Pads, Thermal Pads

At NEDC, we manufacture an incredible array of applications. In today's blog, I thought I’d talk about something we’ve all interacted with at some point. In today's world, we are trying to have the data at our fingerprints all the time. Some of these mobile devices...

Silicone Rubber Gasketing, Peroxide vs. Platinum Cured

Customers buy all sorts of silicone rubber gaskets. In fact, silicone rubber gasketing materials are some of our most popular materials we sell to customers. Of course, theres all sorts of silicone rubber materials. Customers sometimes ask if one is better than the...

Can you use a Thermal Pad/Gap Pad more than Once?

My blogs largely originated from the various questions I have gotten from customers over the years. This includes the most popular ones. One question I realized I get an awful lot is : “Are Gap Pads Reusable?” Heres my short answer, “It depends, but I wouldn’t ever”....

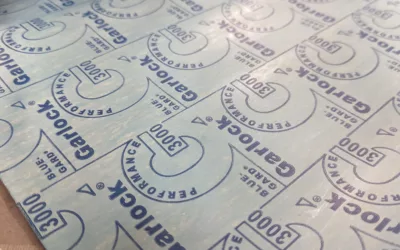

Garlock BLUE-GARD Gasketing Options | Waterjet/Die-Cutting

At NEDC, engineered options are our thing. In this blog, we wanted to discuss all of the Garlock options that are under the BLUE-GARD® brand. These materials are non-asbestos, aramid fiber gaskets that are compressed with different binders. Popular Garlock BLUE-GARD®...

R10400M (Medium) Flame Retardant Silicone Sponge | Custom Die-Cut Parts

Silicone Sponge, and Silicone Foam are different. I’ve talked about that in another blog on our website. Both have desirable properties. Some have good physical properties, and some have good flame retardant properties. There are some products that can actually be...

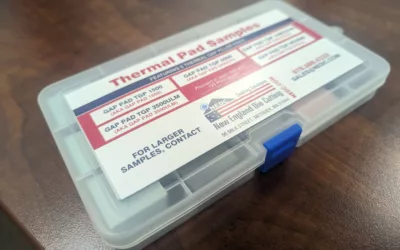

Thermal Pad Tackle Box | Sales Tool for Testing/Sampling

At NEDC, we are all about thermal. We enjoy making new sales tools to help customers design thermal interface pads into their applications. Why use this Sales Tool? This thermal pad tackle box allows the user to try different thermal pads. In this kit, we have 5...

Thermal Pad vs. Thermal Grease/Mica

One common question I hear engineers ask about is if it's better to have Mica/Grease or Sil-Pad products. Obviously, I’m partial to this, but I wanted to give some thoughts I had about Mica/Grease, and why I think it has its place, but why I think in a manufacturing...

Die-Cutting vs Laser Cutting, Epoxy Preforms: Part 2

I had a customer call the other day, saying he heard that laser cutting was better than die-cutting for frozen epoxy preforms. Heres the thought I had in my head “Why does this keep coming up!?” Heres my thought, and then I’m going dive into every advantage, and...

IP Ratings – Gaskets & Ratings | Particles/Liquid Ingress

IP (Ingress Protection or International Protection) ratings are a common way to define how protected an electrical enclosure is from foreign matter that does not belong in the said enclosure. Gaskets are frequently used to provide the protection set forth in this...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of cooking.

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for customers to buy. For that reason, NEDC has many frozen films in stock. These include: Ablefilm 5025E Ablefilm 561K Ablefilm CF3350 Ablefilm 566K And others. We wanted to just get it out there on...

Pure EMI Silver Gaskets, Are They Needed?

Customers ask me for material selection recommendations all the time. One way I believe I build trust with clients is, I don’t upsell things I don’t need to. Customers literally once a week call and say, I NEED VITON! Oftentimes my response is “Hey, I’ll sell you...