EMI Gaskets | EMC Gaskets, EMI Shielding, MIL-DTL-83528

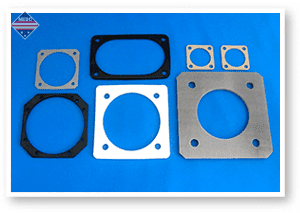

Array of Connector Gaskets

EMI Gaskets play an important role in any electronic design that is attempting to shield EMI from their assembly. In our eyes, there are two different types of EMI Gaskets. There are environmental gaskets, and there are EMI Gaskets. However, some of the solutions below are able to serve both purposes simultaneously. The material below is mainly rubber based materials that are shielding EMI interference.

Electrically Conductive Silicone Rubber/Fluorosilicone Rubber/EPDM Rubber

Commercial/Military Grade Options

Frequently, gasket manufacturers are being asked to certify to the MIL-DTL-83528. This is a widely used specification. These different electrically conductive rubbers really come down to two variables for the selection. There are the particle fillers, and there is the rubber content. Many combinations of these are available. For example, nickel graphite is able to come with EPDM, fluorosilicone, and silicone.

The elastomer options really come down to a few variables which are toughness, temperature range, and fluid resistance. The elastomer essentially binds the electrically conductive particles into the molded/extruded shape to make it electrically conductive while also maintaining an elastic nature. Typically fluorosilicone is utilized for situations where fluid resistance is required. Silicone has always been the good general purpose option for EMI Gaskets. EPDM is usually utilized for outdoor applications that will not see temperature extremes nor fluid contact. Silicone Rubber for NEDC is easily the most popular through MIL-DTL-83528 Type B, however.

Electrically Conductive Fillers Available Table:

The below table highlights the fillers added to the EMI Rubber Gaskets to help impart electrical conductivity. Some can be more expensive than others- but some add more electrical conductivity. Usually the higher the cost of the filler, the more conductivity it adds.

| FIller Particles Available: | Cost($, $$, $$$, $$$$): | Included In the MIL-DTL-83528 |

| Nickel Graphite | $ | No |

| Pure Silver | $$$$ | Yes(Type E, Type F, Type H, Type J) |

| Silver Aluminum | $$$ | Yes(Type B, Type D) |

| Silver Nickel | $$ | Yes(Type L) |

| Silver Glass | $$ | Yes(Type M) |

| Silver Copper | $$$ | Yes(Type A, Type C, Type K) |

| Nickel Aluminum | $$ | No* see below |

| Passivated Silver Aluminum | $$$ | Yes(Type D) |

emi gaskets assortment

Unique Filler Combinations for Custom EMI/EMC Gaskets

Our customers sometimes require a gasket that is an alternative to silver but also low cost, and still has resistance to galvanic corrosion. Cho-Seal 6502, and SSP-2529 are examples of these type of gaskets. These gaskets are an nickel-aluminum filler that is dispersed into a silicone rubber matrix. This is a unique type of gasketing that not only has good shielding effectiveness, but a cost effective structure.

Cost Sensitive Solutions for EMI Gaskets

It is good to note that the electrically conductive rubber also have some cost sensitive solutions that may serve the same purpose. Many design engineers will utilize nickel/graphite filler instead of costly silver based fillers. It has been shown that nickel/graphite can have similar performance in some applications for shielding effectiveness. Although, testing should be key to making sure the solution you are selecting will match the performance requirements.

These gasketing materials are able to be fabricated into finished gaskets through waterjet cutting, or die cutting. However, bonding of gaskets through vulcanizing cord stock. Cord stock is produced through extrusion machines.

Whats Popular when it comes to EMI Solutions?

One of the things we mention a lot on this website is it is important to choose materials that converters/fabricators are familiar with. The reason for this, many converters should be able to get the material quickly, and be familiar with it. In addition, many companies who manufacture electrically conductive gasket materials should have them too.

-Silicone Rubber Silver Aluminum(Normally MIL-DTL-83528 Type B)

-Fluorosilicone Rubber Silver Aluminum(Normally MIL-DTL-83528 Type D)

-Fluorosilicone Rubber Passivated Silver Aluminum(Normally MIL-DTL-83528 Type D Passivated)

-Silicone Rubber Nickel Graphite, a commercial option is EC-2130 by Rogers Corporation

Applications for EMI/EMC Gaskets

-Enclosures with Electronics Components

-Electrical Power Supplys

-Battery Systems

MIL-DTL-83528 Slash Sheets

The MIL-DTL-83528 specification utilizes so-called “slash” sheets to make it easier for design engineers to call out different types of normally custom configurations of these materials. For example M83528/004D001 calls out a Type D connector gasket with a custom configuration of dimensions. There are other slash sheets for flange gaskets, washers, and other configurations.

The different configurations are listed below in the table:

| Slash Sheet | Configuration |

| M83528/001 | Solid O-Strip Channel Extrusion |

| M83528/002 | Molded O-Ring |

| M83528/003 | Solid D-Strip Channel Extrusion |

| M83528/004 | Connector Gaskets(.032’’ thickness) |

| M83528/005 | Molded O-Ring |

| M83528/006 | Molded D-Ring |

| M83528/007 | Hollow D-Strip Channel Extrusion |

| M83528/008 | Hollow P-Strip Channel Extrusion |

| M83528/009 | Solid Rectangular Strip Extrusion |

| M83528/010 | U-Channel Strip Extrusion |

| M83528/011 | Hollow O-Strip Channel Extrusion |

| M83528/012 | Circular Washer Die-Cut |

| M83528/013 | Molded Waveguide Parts |

It is good to keep in mind as well that there are many other extruded options available for EMI Gasketing, some custom ones may include “bunny ears”, or “cowboys hats”.

Modified EMI Rubber Gaskets

There are a number of different options when it comes to modifying a EMI Rubber gasket material into something slightly different than what they normally are available in.

Low Durometer EMI Gasketing Options

Low Durometer EMI Gasketing Options can be numerous. These are reserved for when closure/clamping pressure isn’t dramatic. Options such as :

-30A Durometer

-40A Durometer

-45A Durometer

High Durometer EMI Gasketing Options

High Durometer options are usually already used in the MIL-DTL-83528, however high durometer options such as 80 durometer are available.

Lamination/Converting of EMI Gaskets:

Tape:

There are a number of different tape options that we can offer on EMI Gaskets. Not all EMI Gasketing options require electrically conductive tape. Most of these tapes are known as ECATTs(Electrically Conductive Transfer Tapes). NEDC is a 3M converter, so many of the options are 3M products. Some options for electrically conductive tape include:

3M 9703, 2mil, isotropic, acrylic-based, silver

3M 9707, 2mil, isotropic, acrylic-based, silver

3M 9713, 3.5mil, isotropic, acrylic-based, nickel/graphite

3M 9719, 4mil, isotropic, silicone-based, nickel/graphite

Other Types of EMI Gasketing Solutions and Why to Use?

At NEDC, we cut a number of custom EMI Gaskets out a number of different options including:

-Electrically Conductive Foam

Includes Electrically Conductive Foam from Laird, Chomerics, Schlegel and other OEMs.

-Electrically Conductive Rubber, silicone, fluorosilicone, EPDM, etc.

Manufacturers of the QPL listed MIL-DTL-83528.

-Oriented Wire in Silicone, Fluorosilicone (Sponge, or Solid Rubber)

-Expanded Wire

For that reason, there are a number of cutting options we have including waterjet cutting, die-cutting, and laser-cutting. Each one is selected depending on quantity, or the type of material being cut, along with the tolerancing of the EMI Gasket.

Electrically Conductive EMI Foam Solutions

Electrically Conductive Foam is usually made up two different ways I’ve seen:

A. The foam is covered on both sides with a conductive fabric, knitted wire, or yarn to impart the electrical conductivity to the foam.

B. The foams multi-planar electrically conductivity is imparted by the silver-plated fibers in low density polyurethane foam.

Applications for Electrically Conductive EMI Foam:

-Large Servers, and Desktop PCs

-Telecom Infrastructure racks

-Backplanes, Connectors, and Access Panels

Electrically Conductive Combination Gaskets

Gray Silicone Sponge Gaskets with Mesh Strip

Combination Gaskets are defined as two different materials being bonded together to make it electrically conductive. The electrically non-conductive part makes the environmental seal. Usually it has metal, and a foam, or solid rubber material.

Metals:

-Aluminum Alloy 5056 per AMS-4182,

-Monel QQ-N-281 per AMS-4730

-Copper-Clad Steel per ASTM B520

Rubber/Foams:

-Fluorosilicone Sponge per AMS-3323, ASTM D6576

-Silicone Sponge per ASTM D6576, MIL-R-6130, AMS-3195, AMS-3196

-Neoprene Sponge per ASTM D1056, ASTM D6576, MIL-R-6130

-Fluorosilicone Rubber per MIL-R-25988/AMS-R-25988, AMS-3330

-Silicone Rubber per AMS-3302, AMS-3301, AMS-3303, AMS-3304, A-A-59588, ZZR765

-Neoprene Rubber per AMS-6855, MIL-R-6855

Oversized EMI Gasketing Options

One thing to keep in mind when designing an EMI Gasket is many times electrically conductive rubber options are molded sheets. For this reason, beyond 24’’ in any one direction can be difficult to fabricate out of a single piece of EMI material. In these cases, it may be a good idea to specify how the gasket can be put together. There are electrically conductive adhesives available for fabricating bigger gasket shapes by vulcanizing separate pieces together and then cutting a complete shape.

More Information:

For more information on electrically conductive gasketing products, please contact our sales department.

Popular Blog Post

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of cooking.

Previous Posts

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for...

Pure EMI Silver Gaskets, Are They Needed?

Customers ask me for material selection recommendations all the time....

Can you use a Thermal Pad/Gap Pad more than Once?

My blogs largely originated from the various questions I have gotten from...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of cooking.

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for customers to buy. For that reason, NEDC has many frozen films in stock. These include: Ablefilm 5025E Ablefilm 561K Ablefilm CF3350 Ablefilm 566K And others. We wanted to just get it out there on...

Pure EMI Silver Gaskets, Are They Needed?

Customers ask me for material selection recommendations all the time. One way I believe I build trust with clients is, I don’t upsell things I don’t need to. Customers literally once a week call and say, I NEED VITON! Oftentimes my response is “Hey, I’ll sell you...