Custom Die Cutting

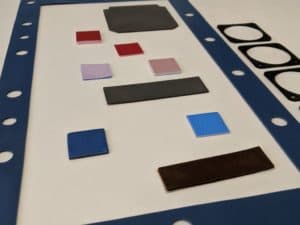

Gaskets, Thermal Pads, Absorbers, Epoxy Films and Electrical Insulators

Custom Die Cutting is NEDCs core competency. We offer custom die cutting through steel-rule dies. This enables us to offer essentially unlimited customization. This is because we can provide a steel-rule die with specific shapes, cut-outs, and diameters along with the ability to cut a specific material. Since these shapes, sizes, and materials are essentially endless our ability to produce custom gaskets, thermal pads, absorbers, and epoxy films are also endless.

What is Die Cutting?

assortment of die-cut parts

The modern way to “die cut” is to take advantage of all the uses of the steel rule die. The steel rule die is essentially a piece of durable wood such as maple that has “rule” in it; one side of the rule is sharpened. This steel rule is bent into the shape of the part and placed into the wood to create a tool that is very durable. The steel rule offers an economical solution to manufacture a quality product for large-scale runs. These steel rule dies “die-cut” hundreds of different shapes, and sizes of parts that range from extremely complex to very simple. One of the biggest benefits of dies is their durability, and their low cost. Some dies can be good for a million hits or more depending on the material.

The equipment is all that is needed to manufacture a quality part. A die-cutting machine comes down with enormous pressure, and precision to “burst” the die through the material. Modern die-cutting machines offer computer algorithms and lightning fast die cutting ability. Our modern die-cutting machines utilize coordination of computers, hydraulics, and nesting software to offer our customers the best price. Part of custom die cutting is the ability to match our customers needs to what our machines and tooling can do.

When many people talking about “die-cutting” they are usually referring to the in-home use machines that can parts out. In our world, die-cutting is large scale manufacturing of non-metallic parts for commercial, aerospace, and electronic customers. We are a die-cutting manufacturer.

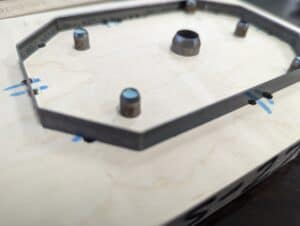

What does a Steel Rule Die Look Like?

The below image is what a typical steel rule die looks like. You see “steel rule” and you also see some “punches.” Depending on the shape, and complexity of the part being manufactured, a mix of punches and steel rule is used. The steel rule die manufacturer may change the punches/rule types to get the part they are cutting to come out different. Each material that the die-cutter is making is different so each die is custom tailored to that material type.

steel rule die with punches

Capabilities of Die Cutting:

One of the advantages of die-cutting is the reproducibility of every cut. The part is made by the die, and the die is naturally stronger than the material itself, so it helps in producing a quality part over and over. The shape of the part is dictated by the rule of the die which stays in place due to the wood and the pressure of the machine that is being used. Nearly every cut is within a few thousandths of the last cut. One of the limitations of the steel-rule die is the tolerance. Steel-rule dies can be manufactured to hold a +/- .005” tolerance. However, it may be difficult to stay within that tolerance on a very complex part such as extremely thick foam materials or extremely dense materials.

Concavity, or hourglassing is a common phenomenon known to die-cutters. Luckily, NEDC offers a solution to this problem as well, (see Waterjet Cutting). It is also possible to hold a +/- .002” tolerance with a solid tool on select parts; NEDC provides solid tool cutting as well. Solid tools can have a prohibitively expensive cost if not cutting a lot of pieces. Die cutting normally offers a two-dimensional part (X and Y axis); it is possible to offer some parts as three-dimensional, through bends. This is rare but can be done with some rigid, thin materials. Die Cutting also offers the ability to “kiss-cut,” this is described in our article on “Kiss-Cut Parts“.

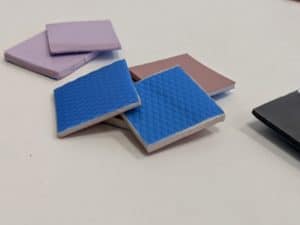

thermal pads die cut

Quantities involved in Die Cutting:

It is possible to manufacture a die with more knife bent into the configuration to make more parts with each ‘hit’. This is done often when there are many parts required. It is also helpful when nesting the part may offer a more effective price structure for our customer. It is normal for the price to go up on the tool when there are more parts offered per ‘hit’. When we add more cuts per hit, we call the tool a higher “up”. For example, that die, is 10-up meaning with every hit, it cuts 10 parts. NEDC offers die cutting for quantities ranging from very high such as 1,000,000 pcs to 1 pc.

Materials Available for Custom Die Cutting:

NEDC now offers a large variety of high-performance materials that may be die cut. These materials include silicone, fluorosilicone, nitrile rubber, EPDM rubber, electrically conductive gasketing materials, thermal management, as well as many other types of materials (see our products list). Some of the parts NEDC has the capability to die-cut are gaskets, thermal pads, epoxy preforms, and absorbers. Of course with custom die cutting, NEDC offers a wide array of materials to be die-cut.

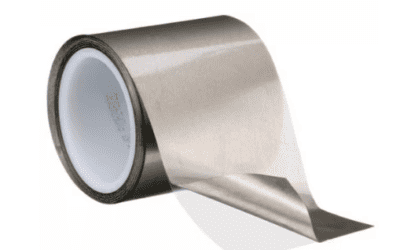

Another bonus of modern custom die cutting is the ability to offer pressure sensitive adhesive on the back of parts with ease of removal. There are many types of adhesive backing that can be provided with a part. These tapes can be acrylic-based, rubber-based, or silicone-based. This oftentimes depends on the application. NEDC is an authorized converter of 3M. For that reason, we offer many different types of adhesives on the back of its parts:

- Thin Films such as Nylon, Mylar®, ETFE, PTFE, UHMW, and DuPont’s Kapton®.

- Adhesives, such as the wide range 3M offers: VHB(very high bond) Tapes, Acrylic Transfer Tapes, Single Sided Tapes, Double Sided Tapes, and more.

- Fabrics such as Aramid Felt, Nylon Felt, and others

- Rubber Gasketing materials such as Fluorosilicone, Fluoroelastomer(Viton), Chloroprene(Neoprene), Buna-N, EPDM, Silicone Rubber, Epichlorohydrin, and others.

- Thin Foils such as Copper Foil, Aluminum Foil, Tin-Copper Foil, and others.

- Aramid paper Products such as DuPont’s Nomex®

- Thermal Interface Pad materials such as Gap Pads, Thin Thermal Interface Pads, Phase Change Pads, Double Sided Tape Pads, and others. (NEDC has common power supply/other component steel rule dies on hand for certain configurations).

For more details on the materials available for NEDC to procure, see our Tech Blog.

When does Die Cutting not Make Sense?

We thought since our main selling point is die-cutting, we would also present examples where conventional die cutting does not make sense. There are situations where die cutting does not make sense, such as mentioned above with concavity issues on thicker materials. Below we list a few reasons where it makes sense to hunt for alternative to die-cutting.

A. Its a thicker material. Concavity can be a concern with thicker materials. There are tricks of the trade to get around this to a certain degree, but ultimately it may be more wise to accept the material is too thick to die-cut.

B. Tolerancing. Tolerancing can be a tricky challenge, depending on the size of the part, and the cut-outs and tolerancing of those shapes, sometimes it makes more sense to move to another type of fabrication method, such as laser cutting, or waterjet cutting.

C. Many Cut-Out Shapes. There are times when literally hundreds of cut-outs are in a part. This can become tricky because die-cutting ultimately is a somewhat unbalanced manufacturing method. Two surfaces come together to force the die to burst through the material. For that reason, not all the surfaces perfectly burst at the same time. When many cut-outs are on a part, pressure, and getting a good part consistently may become a challenge.

About NEDC:

NEDC(New England Die Cutting) is a custom die cutting manufacturer in Methuen, MA with a 77,000 sqft facility. If you have any questions concerning custom die cutting or our die-cutting process please contact our Sales Team at sales@nedc.com.

Die Cutting Blog

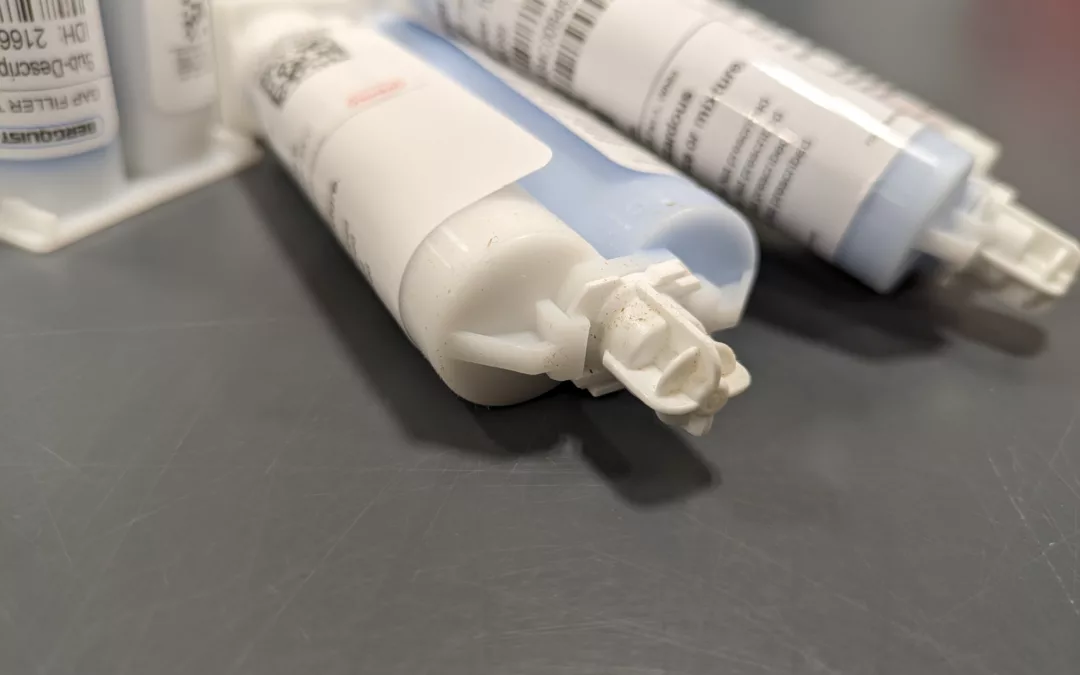

Thermal Gap Filler | NEDC distributes TGF 3600/GF3500S35 | Information

At NEDC, some say we are experts in thermal gap pads. We are also experts in liquid gap filler materials. So much in fact, we actually distribute both. One of the materials we like a lot, and will be highlighted in an upcoming video is TGF 3600, or...

Previous Posts

NEDC Launches Video Demonstrating How Thermal Pads Work!

<iframe width="1519" height="526"...

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of...

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for...

HPMS Graphite | Flexible Graphite | Custom Die-Cut Parts

At NEDC, we like to think we are experts in thermal interface materials. Flexible graphite material is an excellent thermally conductive material. In fact, I see a lot of thermal interface pads going in this direction due to its great thermal conductivity, & low...

Are Electrically Conductive Gaskets, Thermally Conductive ? | A Test Analysis

Recently, we procured a thermal performance testing machine. I thought it’d be fun to test what EMI/RFI gasketing thermal conductivity is(I’ve been testing everything I can get my paws on, haha). In this test, we decided to measure the thermal conductivity/thermal...

Thin Gasketing Options | .015”, & Below | High Performance Gaskets

Applications get smaller, and smaller everyday. As footprints of the electronics we serve get thinner, and lighter i.e electronic signs, tablets, and other peripherals, the gasketing must get thinner to accommodate it. We have customers come in all the time looking...

T-Global Technology | Thermal Gap Pads | Thick, Thin, High W/m-K

At NEDC, thermal pads are our specialty. Our manufacturing site is in Methuen, MA. Across the pond, in the United Kingdom, there is a reputable thermal pad manufacturer. This manufacturer is called T-Global Technology. They make a number of thermal interface...

EMI/RFI Bulb/Hollow Gaskets – The Softest EMI/RFI Gasket

At NEDC, we mostly die-cut, knife-cut, or waterjet cut gaskets. However, we do also fabricate, glue, or bond together some gaskets. Why do we do this? The short answer is because we cannot die cut, or waterjet cut them. However, sometimes it's also for performance...

Low Durometer/Soft EMI/RFI Gaskets – 30A, 40A, 50A Gasketing

For years, NEDC has supplied low durometer gasketing materials to customers. One product that I realized has been underutilized the last few years is “low durometer EMI Gasketing”. On this website, we are making a large push to show we are a gasket manufacturer who...

Nickel Coated Aluminum Gaskets | EMI Gaskets | Corrosion Resistant Gaskets

EMI Gaskets are not a new technology. They have been around for the last 60 years. However, once in a while a new technology emerges for a different type of foam, or a different type of orientation of materials. Over the last few years, a new type of particle has...

Applications: Scanner, PDDs, Analyzers – Gaskets, Pads, Thermal Pads

At NEDC, we manufacture an incredible array of applications. In today's blog, I thought I’d talk about something we’ve all interacted with at some point. In today's world, we are trying to have the data at our fingerprints all the time. Some of these mobile devices...

Silicone Rubber Gasketing, Peroxide vs. Platinum Cured

Customers buy all sorts of silicone rubber gaskets. In fact, silicone rubber gasketing materials are some of our most popular materials we sell to customers. Of course, theres all sorts of silicone rubber materials. Customers sometimes ask if one is better than the...

Why Commercial EMI/RFI Gasketing | Custom Die-Cut EMI Gaskets

At NEDC, we sell gaskets, lots of them. I would love nothing better than to sell a fully loaded pure silver gasket. Love it. However, I’ll be honest, I don’t think that's necessary most times. When customers have all the money in the world to spend, sometimes I wish...

LOCTITE® Thermstrate 2000 aka TCF 1000AL | Die-Cutting/Converting

At this point, I’ve written 250 blogs on this website- I know, I am even like, how much of a thermal pad geek am I? Why did I ask this question? I was curious if I have written a blog about LOCTITE® Thermstate 2000 Phase Change material. At one point, we had written a...

Long Shelf Life Electrically Conductive Single/Double | EMI Shielding Tapes

We are a 3M converter, and if I’m being honest, I don’t throw a party everytime they come out with a new product. I like new copper foil products, and new VHB Tapes just like the next guy, but nothing gets me going like: “LONGER SHELF LIFE ELECTRICALLY CONDUCTIVE...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of cooking.

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for customers to buy. For that reason, NEDC has many frozen films in stock. These include: Ablefilm 5025E Ablefilm 561K Ablefilm CF3350 Ablefilm 566K And others. We wanted to just get it out there on...

Pure EMI Silver Gaskets, Are They Needed?

Customers ask me for material selection recommendations all the time. One way I believe I build trust with clients is, I don’t upsell things I don’t need to. Customers literally once a week call and say, I NEED VITON! Oftentimes my response is “Hey, I’ll sell you...