3M 8815 Thermally Conductive Tape

Since the founding of a company called Minnesota Mining Manufacturing in 1902, 3M has been inventing, and offering a number of different tape products. The modern 3M company now offers an incredible variety of tapes, including but not limited to electrically conductive transfer tapes, acrylic tapes, silicone tapes, and rubber based tapes. One of the tapes that NEDC recently encountered and subsequently die cut was 3M’s Thermally Conductive Transfer Tape 8815.

3M 8800 Series/Properties and Applications

3M 8815 is part of the 8800 series. The series of tape are designed to be a thermally conductive tape that can be used in a number of applications seeking to get rid of heat while also requiring bonding power. This series comes in a variety of thicknesses that are listed as different tape numbers: 8805, 8810, 8815, and 8820. The thicknesses are 5mil, 10mil, 15mil, and 20mil respectively; these tapes offer:

- High Mechanical Strength

- Exceptional Shock Performance

- Halogen free [1]

- Great for thin bonding applications

These tapes also offer impressive adhesion, which is demonstrated by a 90 degree peel (oz/in) after 15 minutes, with values (in the same order as above) of 35, 46, 53, and 60.* The tapes offer great wetting out properties and flow nicely onto many surfaces. Typical applications utilizing these tapes are: heat sinks, fans, heat pipes, heat spreaders, or other cooling devices. These tapes feature a thermal conductivity of .60 (W/m-K). These tapes utilize a ceramic filler in an acrylic base, and come with a silicone treated polyester liner to facilitate easy removal before applying in the application.

More Information/Details

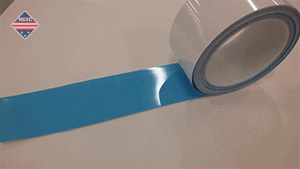

The color of these tapes is an elegant white, but the liner on the tight side of this material comes as an elegant blue PET. It is important to note that this adhesive has a shelf life of 12 months.[2] As an authorized converter (die cutting, slitting, etc.) for 3M, NEDC has the ability to offer the tapes above in roll or converted part form- even “kiss-cut”. NEDC can also supply most parts with this transfer tape adhered to it. For more information on 3M’s thermally conductive tape products that NEDC converts, and distributes, please contact sales@nedc.com.

[1] “Halogen free” is defined as having maximum 900 ppm bromine, maximum 900 ppm chlorine, and/or maximum 1500 ppm total bromine and chlorine, per IEC 61249-2-21.

[2] Oftentimes, elevated shelf lives will be asked for on tape products. It is important to note that OEM’s of tape products are typically defining shelf life in roll form, not as a finished converted product.

*This was on an aluminum substrate that was untreated.