Connector Gaskets describe a type of gasket that has the geometry that would be conducive to a surface found in many connectors. This can be for two reasons. One is the requirement to have an environmental seal. The other being that EMI/RFI shielding capability is required. When it is both, an EMI gasket is usually the perfect solution. However, there are cases where electrically non-conductive materials would be a better choice, such as with an interfacial seal for pin gaskets.

Type of Connector Gaskets

Subminiature D-Gasket

These gaskets are the conventional type you would see in the back of a computer. These rectangular connectors are normally made out of a EMI gasketing material for both EMI and environmental protection. The standard thickness on these gaskets is .032’’ in thickness. The shell sizes range from 9 to 50 pin.

Conventional Connector Gaskets

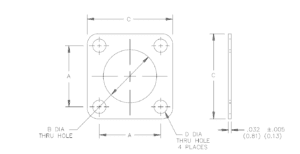

These gaskets are available from the slash sheet MIL-DTL-83528/4. They are usually circular in shape in the middle with radii on the corners. They can either be slotted or with holes. The M83528/4 is strictly circle diameter screw holes. The standard thickness on these gaskets is .032’’ in thickness. NEDC commonly deals with MIL-DTL-38999 type gaskets.

We thought it would be useful to make a table of different M83528/4 that NEDC traditionally either has in stock or can turn very quickly. The reason for this is these gaskets are so commonly used that any die-cutting manufacturer typically has stock of the steel-rule dies that are required to make these parts.

Breakdown of M83528 numbers

M83528/LLLXDDD

M83528=MIL-DTL-83528 (the overall specification)

LLL=Slash Sheet(in this slash sheet indicating connector gaskets)

X=Material Type, (Several Material Types Available, Type B, and Type D most popular)

DDD=The size (34 sizes available)

Fast-Turn Connector Gasket Pin #s

| M83528/004X001 | M83528/004X007 | M83528/004X013 | M83528/004X019 | M83528/004X025 |

| M83528/004X002 | M83528/004X008 | M83528/004X014 | M83528/004X020 | M83528/004X026 |

| M83528/004X003 | M83528/004X009 | M83528/004X015 | M83528/004X021 | M83528/004X027 |

| M83528/004X004 | M83528/004X010 | M83528/004X016 | M83528/004X022 | M83528/004X028 |

| M83528/004X005 | M83528/004X011 | M83528/004X017 | M83528/004X023 | M83528/004X029 |

| M83528/004X006 | M83528/004X012 | M83528/004X018 | M83528/004X024 | M83528/004X030 |

| M83528/004X031 | M83528/004X032 | M83528/004X033 | M83528/004X034 |

Electrically Conductive EMI Gasketing Materials

There are many different types of EMI gasketing materials available for use. One of the more common materials NEDC sees is silver/aluminum filler with either fluorosilicone or silicone rubber. These materials are called out in the MIL-DTL-83528 as Type B and Type D. They are the most commonly used gasketing materials for the M83528/004 pin number.

Type D has shielding effectiveness of 90 dB @ 10 GHz. Type D is a Fluorosilicone Rubber material filled with either passivated or non-passivated silver/aluminum particles.

Type B has shielding effectiveness of 100 dB @ 10 GHz. Type B is a Silicone Rubber material filled with silver aluminum particles.

However, the MIl-DTL-83528 provides other different types of materials including Type A, Type C, Type E, Type F, Type J, Type K, Type L, and Type M.

More Information on Electrically Conductive Connector Gaskets

For more information on connector gaskets please contact sales@nedc.com. NEDC uses waterjet cutting and die cutting to convert gasketing materials into connector gaskets.