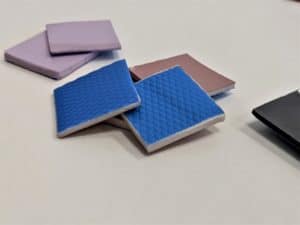

thermal gap filling pads

At NEDC we cut a lot of thermal gap filling pads. One of the frequent questions we get is “Why are many thermal pads not available with pressure sensitive adhesive?” The answer comes back to the whole purpose of the thermal pad itself.

Attachment Methods

Thermal Interface Materials are designed to reduce air-gaps, and provide a good interface to transfer heat through the material, and then out of the application. For self-attaching methods, there are two options. There is a natural-tack, and there is pressure sensitive adhesive:

Soft-Tack/Natural-Tack

Soft-Tack: Many gap filling pads come with a natural tack on one side. Many of the natural tacks that are available on thermal gap filling pads are sufficient for staying power and sometimes act as adhesives. I have stuck metal plates together with Gap Pads, and upon heating have been unable to remove them from each other without strong intervention. We have seen customers apply thermal gap filling pads using strictly their natural tack to metal enclosures for example. Most Gap Pads are available with natural tack on both sides. There are two Sil-Pad options with natural-tack, Sil-Pad 1500ST, and Sil-Pad 1100ST. The natural tack is a good solution to allow attachment and surface wetting without the costly thermal impeding PSAs. Gap Pad VOUS, Gap Pad VOS, and Gap Pad VO by Henkel are all available with a natural tack on one side with pressure sensitive adhesive coating on the other.

Pressure-Sensitive Adhesives(PSAs)

Pressure-Sensitive Adhesive(PSA): As mentioned above, pressure sensitive adhesives will add thermal resistance to the thermal solution. Thermal impedance or thermal resistance are more important than thermal conductivity when it comes to the application. The pressure sensitive adhesive oftentimes increases the thermal resistance by a small amount that can start to make a large difference in the application. According to Henkels’ Sil-Pad Selection Guide one layer of adhesive could easily increase the thermal resistance by 0.2C/in2/W. However, there are thermally conductive adhesive coatings(TAC) that will help to reduce this thermal resistance a little – although it still leaves more thermal resistance than without it.

For more information on thermal gap filling pads, and their attachment methods, please contact sales@nedc.com.