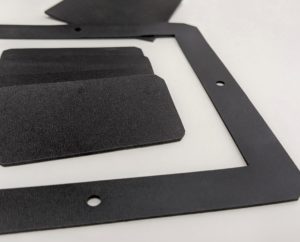

poron gaskets

My furnace at home is 95% fuel efficient. I was told this is among the best money can buy. After removing the lid to the furnace I noticed a strip of foam that looked very familiar. It was PORON® Urethane Foam. PORON® Urethane Foams are among the many different materials we encounter everyday. Each material has a place, but some have properties that can force them into many demanding, and unique situations. However, PORON® has a unique place with its great properties in its economical, yet versatile use in many industries, and applications.

Properties of PORON® Microcellular Urethane Foam

This foam expresses itself through its many great properties. These polyurethane foams have great compression set resistance. In fact, it offers some of the lowest compression set values out of many competitive rubber product selections. PORON® offers low outgassing. It contains no plasticizers or residual chemicals that may leech into the application. In addition, PORON® exhibits great chemical resistance that is very impressive. It features a wide range of temperature resistance. However, different PORON® products vary their temperature resistance. One fantastic thing about PORON® is there is lots of data on outgassing, temperature, electrical & thermal properties, along with traditional physical properties such as elongation, hardness, tensile and others. A quick purview of one of the datasheets below shows an impressive amount of data gathered on these foams by Rogers. In addition certain PORON® products are already certified to several standards including UL-508, and UL-50E making it a go-to selection for many engineers. In regards to UL, most PORONs are capable of meeting UL 94 HBF, a flame retardant specfication. Given all these impressive properties Poron® is commonly used as gaskets in many demanding environments that may encounter dust, rain, oil, and heat.

Special Grades of PORON® Available

PORON® is a very unique family of products for a few reasons. The plethora of properties mentioned above is one reason. However, another is the large availability of Special Grades of PORON®:

-Flame Retardant PORON® V-0 Foam

-AquaPro ® Series for water sealing

-Reinforced PORON® with a PET support carrier borne on (supported)

Applications that Utilize PORON® Microcellular Urethane Foam Gaskets/Pads

-Battery Cushioning Pads

-Dust Gasketing

-Water Sealing/Gasketing in highly compressed cases, except Aquapro®

-Low Outgassing Gasketing

How Much to Compress?

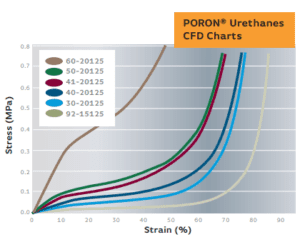

Compression is usually measured through CFD(Compression Force Deflection). It is good to note that while PORON® can be used as a watertight seal, great compression is required along with exceptions of its capability. For general dust sealing, very little compression is required. For example, my furnace uses hand tightened knobs as the compression choice. However for water sealing, 50% compression and above of PORON® will usually create a strong enough seal to prevent ingression of light fluids such as splashing or adjacent rain. Tablets, heat covers, protective casings, gap filling are just a few applications. Some common Rogers products NEDC deals with are: 4701-30(Very Soft), 4701-40(Soft), 4701-50(Firm), 4701-60(Very Firm). Porons come with smooth consistent skin on both sides making topology challenges easier to handle. The graph below shows how much to compress PORON® for certain deflection values.

Cutting/Converting Services

NEDC is a converter/die-cutter of urethane foams. NEDC frequently die-cuts/waterjet cuts PORON® into custom shapes for gaskets, vibration dampening, shock absorbers and other products. Typically NEDC provides PORON® in custom die-cut shapes- however, NEDC does provide stripping with tape backing. Some tapes NEDC uses are 3M 9472, 3M 9485PC, 3M 467MP, and others.

Availability of Poron Urethane Foam®

These foams come in a variety of selections. Some of the variables include density differences, different hardness, colors, supported/unsupported, inserts, thinner/thicker and more. The typical color of many of these urethane foams is black but may change depending on the product. NEDC commonly die-cuts, or waterjet cuts PORON® foams into custom shapes for its customers. For more information on PORON® Foam products, or die-cutting/waterjet cutting, please contact sales@nedc.com.

Technical/Availability Data Downloads

PORON-Urethane-Solvent-Resistance

Material Selection Guide Download

Poron® 4701-30 Datasheet Download

Poron® 4701-40 Datasheet Download

Poron® 4701-50 Datasheet Download