emi gasketing, passivated options

NEDC manufactures gaskets of all sorts. Our arena of play in the gasket world usually is high value gasketing materials. For that reason, a lot of the build to print items we see include “SILVER FILLED” or “SILVER – COPPED FILLED” A question we get very often, is “What is the difference between PASSIVIATED SILVER ALUMINUM, and SILVER ALUMINUM FILLED”. Great question.

The Difference between Passivated/Non-Passivated:

Each conductive gasket has metal particles that fill it. These metal particles are filled at a high percentage. This varies from manufacturer to manufacturer. However, the percentage of fill ranges from 60% to 80% by volume. This is an important detail because now you know- by volume most of this gasket is filled with these type particles.

What is Passivation?

PASSIVATED SILVER ALUMINUM fluorosilicone gaskets is essentially a coating on the particles of silver- aluminum. It is designed to make the gasket more inert to weathering/salt-spray than other types of gaskets.

Why is Passivation important for EMI Gaskets?

Here’s the thing. The government has this salt-spray test to test corrosion resistance. This test is usually a 168 Hour Salt Spray/ Salt Fog test. This is mainly used to test galvanic corrosion. Note: Since the advent of these type gaskets- other types of gasket have also come out that are good for galvanic corrosion such as nickel-plated aluminum.

What not all Gaskets are this way?

Two Reasons:

- Passivated Silver Aluminum is going to cost you more for sure. I see some manufacturers who charge 50% more for their passivated silver aluminum gaskets than their normal silver aluminum gaskets.

- Passivated Silver Aluminum is something that came out in the early 90’s AFTER the regular silver aluminum filled gaskets came out when these technologies were first created. For that reason, many customers have always used the non-passivated versions, and got by just fine. So this created a legacy of having plain silver aluminum gaskets in applications, and in memories, testing.

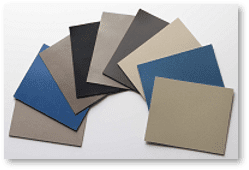

Types of Passivated Silver Aluminum Fluorosilicone Gasketing by Manufacturer

Cho-Seal 1298, by Parker Chomerics- certified to Type D, MIL-DTL-83528

SSP-550-70, by Specialty Silicone Products- certified to Type D, MIL-DTL-83528

SAS Sealtron 1157 by SAS Industries- certified to Type D, MIL-DTL-83528

5000-F-P by East Coast Shielding- certified to Type D, MIL-DTL-83528

More Information on Passivated EMI Gaskets

NEDC waterjet-cuts, knife-cuts, and die-cuts EMI gaskets all the time. For more information on EMI conductive gaskets, or you believe you have an application that could utilize EMI gaskets, please contact sales@nedc.com.