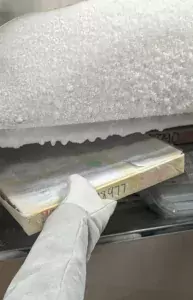

ablefilm sheets

I had a customer call the other day, saying he heard that laser cutting was better than die-cutting for frozen epoxy preforms. Heres the thought I had in my head “Why does this keep coming up!?” Heres my thought, and then I’m going dive into every advantage, and disadvantage.

Laser-Cutting vs Die-Cutting, What should I go with? Rule of Thumb

IF you can get away with die-cutting, DO IT. If not, LASER is probably fine, but be careful who you have laser-cut them. Why do I say this? Well, it can be a guy in his garage with a laser cutting them. The reason I think I’m an authority on this subject is because NEDC provides both die-cutting, and laser-cutting- and frankly, it does not matter to me one bit if a customer has a preference.

Different Metrics

1. Lead-times

Lead time is a 50/50 for me. Here’s why: For the first time you do the job, yeah it’s an additional week or two.. But after that I’m going to argue die-cutting is faster. Why? We have three laser cutters, and we have 7 clicker presses. Which one wins in a pretend backlog situation? That’s not abnormal for any converter worth their weight. Besides, an average preform with more than one cut out is going to take way longer than die-cutting. (I’ve been watching die-cutting machines, and lasers move since I was 6.. So I know)

2. Cut Quality

I addressed this in laser-cutting vs die-cutting epoxy preforms part 1.. I think the cut quality on die-cutting is better, and should be used when possible- but again laser-cutting is a close second in the hands of a good operator/company.

3. Flexibility for revision changes

Easily laser-cutting wins here.

4. Maximizing material usage

Laser cutting wins here, but not by much. Our most seasoned die-cutter can see things that our newest laser operator can’t. In theory laser cutting is going win everytime.. But keep in mind, the guy doing the laser cutting is different than the guy programming it.. OR HE BETTER BE. So if the sheet comes in a little bigger.. So be it… the die-cutter operator might get a slightly better yield, while the laser guy is going run the program he has.

5. Tight tolerance

On a cost basis, laser cutting is probably going win- but don’t sleep on die-cutting options. I can name 4 different types of tools sitting at my kitchen counter writing this blog. Not to mention some other fancy schemes I can think up that can mix, and match those. So, yeah laser-cutting is better in general but die-cutting can get fancy quick too.

6. Sets of multiple parts

I think die-cutting wins here. A clicker operator can easily separate at the machine, while laser-cutting usually would involve dropping them off to another operator to separate them. Which feels like the same thing, but in practice, doing it as one operation is so much simpler.

7. Die Sharpening

I put this one in here, although I felt kind of silly doing it. Anyone who has die-cut parts for more than 2 weeks knows.. Die Sharpening usually only occurs in tough to cut materials. Jobs that your doing:

A. Thousands of parts

B. Hard to cut materials, such as Thick Fiberglass(not the one in Ablefilm), Hard Plastic, Other Metals

More Information

For more information on the pros, and cons of laser-cutting and die-cutting when it comes to epoxy preforms, please contact sales@nedc.com.