RF/Microwave Absorbers

Microwave Absorbers

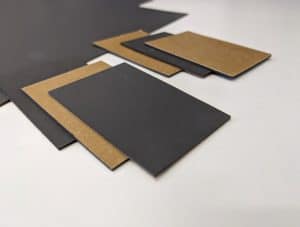

NEDC manufactures RF/Microwave absorbers into custom shapes through die-cutting, and waterjet cutting. Microwave absorbers have been used in military applications since their inception. However, more and more microwave absorbers are used in commercial applications. Applications such as computers, consumer electronics, network servers, and wireless antenna systems are common with microwave absorbers.

What are Microwave Absorbers?

Oftentimes electronics can cause cavity resonances inside of electronic enclosures. Different types of microwave absorbers can be employed to attenuate the signal. The problem with normal EMI gaskets is they can actually exacerbate the problem by creating an additional conductive surface. This contains the issue within the cavity. Microwave Absorbers function by eliminating cavity resonances through lossy magnetic materials. Magnetically loaded elastomers are most seen by NEDC. Oftentimes electrical engineers will pick and place the microwave absorbers along the enclosure and then test the device. This is usually preferable to the time-consuming and complex nature of selecting a material by modeling.

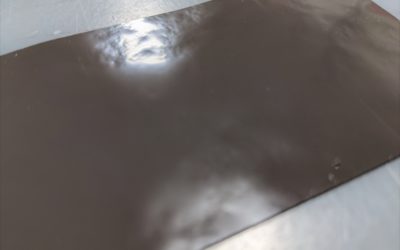

eccosorb gds, die-cut

eccosorb gds, die-cut

What type of Microwave Absorbers are available?

There are a few different considerations when reviewing the different types of absorbers available. There is frequency ranges, elastomers, and differently loaded materials.

Dielectrically Loaded Materials

Dielectrically Loaded materials are typically foam materials coated with carbon. These foams are open-cell elastomers that can be made up of multiple layers. Obviously these foams are much thicker than their magnetically loaded elastomer counterparts. They range from .125”(3.2mm) to 2.00”(5.08mm) in thickness. This is a drawback with these foams. At .125”(3.2mm) being the thinnest available size can become a concern. With smaller and smaller packages coming to market size matters.

Magnetically Loaded Materials

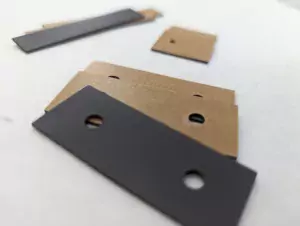

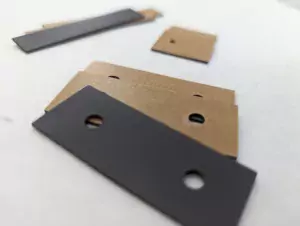

NEDC commonly deals with elastomeric like absorbing materials. These materials are typically magnetically loaded with iron-based fillers. Different loading levels of the ferrous fillers affect the level of attenuation. Manufacturers design different absorber materials to withstand different environments. Oftentimes silicone rubber is the binder material, but other materials such as nitrile, neoprene, and urethane can be used. However for NEDC, silicone-based elastomers are still the most commonly seen. This is because silicone offers a great balance of temperature range, availability, Different manufacturers offer different options for different applications including high-temperature, different frequency requirements, and assembly options. NEDC cuts magnetically loaded absorbers as thin as .010’’ to as thick as .250’’.

Broadband Absorbers

Broadband is the largest category of microwave absorbers. These products operate over a bigger frequency spectrum. Broadband absorbers are much more available. For that reason, NEDC deals with mostly broadband microwave absorbers. They offer a great price point that ultimately offers great value for most applications.

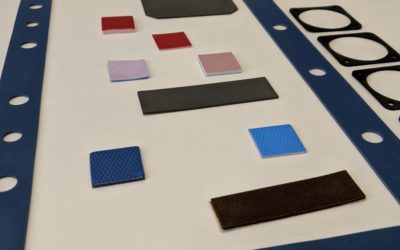

absorber die-cut

Narrowband Absorbers

It is good to keep in mind that while broadband absorbers are more available, narrowband absorbers exist. These narrowband absorbers absorb at a specific frequency. Custom thicknesses, and formulations can help address more narrow frequencies that may need to be attenuated. Many different manufacturers offer microwave absorbers. Finding the right one for your application may take time, but there are many options available.

Manufacturers of Microwave Absorbers

- Laird

- 3M Company

- Mast Technologies

- 3G Shielding

- Cuming Microwave

Cutting Methods/Application Notes on Microwave Absorbers

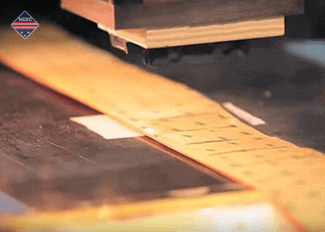

NEDC die-cuts and waterjet cuts these materials into unique shapes. Typically, absorbers are placed in enclosures two ways. The first is through the use of RTV(room-temperature vulcanizing) adhesives. These RTVs usually take time to cure, and are a bit more labor intensive. The second is through the use of tape. Most absorbers are available with tape backing to enable easy placement of the absorbers onto different surfaces. However, it is good to keep in mind the surface the absorber is being placed on when choosing either method. When using either method of application, a properly cleaned surface, and following the manufacturers datasheet is critical.

For more information on RF/microwave absorbers, please contact sales@nedc.com.

RF Absorbers Blog

HPMS Graphite | Flexible Graphite | Custom Die-Cut Parts

At NEDC, we like to think we are experts in thermal interface materials. Flexible graphite material is an excellent thermally conductive material. In fact, I see a lot of thermal interface pads going in this direction due to its great thermal conductivity, & low...

Previous Posts

Long Shelf Life Electrically Conductive Single/Double | EMI Shielding Tapes

We are a 3M converter, and if I’m being honest, I don’t throw a party...

Thermal Interface Pads/Liquids for Solid State Drives(SSDs)

As the industry moves from hard-drives(HDDs) to solid-state drives(SSDs)....

Engineering Note: Hole Diameters: How low can you go?

At NEDC, cutting gaskets is what we do. Gaskets typically have holes in...

STAYDRY® H2-3000 | Die-Cutting/Contract Assembly

NEDC die-cuts a lot of different types of materials. I often say a material is unique, because it's true they are all unique. However, one material that does not have peers is truly unique in its own rite. STAYDRY® H2-3000 manufactured by Macdermid Alpha is a Hydrogen...

What do we make at NEDC?

A lot of times when I’m explaining to someone what I do for a living, I almost feel like saying “I play with giant cookie cutters all day.” We Use Giants Cookie Cutters, why say this? To most people it seems hard to explain that our customers just send me a print and...

Tips for Choosing a Tape for your Adhesive Backed Gasket!

At NEDC we manufacture a lot of different components for aviation, military, medical and electronics. One of the common things we see is trouble with adhesive transfer tapes. In this blog post, we wanted to discuss some tips on choosing the right tape for your...

PGS Thermal Graphite Sheets | Custom Die-Cut Shapes

Thermal management is a core competency at NEDC. One of the core products we die-cut is graphite-based thermal interface material. Panasonic has a line that features incredible thermal performance! Panasonics PGS(Pyrolytic Highly Oriented Graphite Sheet) Thermal...

3M 467MP Transfer Tape- Benefits, Availability, Cutting

At NEDC, we laminate a ton of different materials. One of the tapes we use most commonly is 3M 467MP Transfer Tape. We laminate it to thin films, and gaskets to help customers in their assembly process. It is one of my favorite adhesive transfer tapes. In this blog, I...

Die Cut Gaskets vs. Laser Cut Gaskets vs. Waterjet Cut Gaskets

At NEDC we operate many pieces of cutting machinery. We operate state of the art conventional die cutting machines, laser cutting machines, and waterjet cutting machines. In this blog post, we thought we would delineate the differences between all of these machines so...

EMI/RFI Absorber Tapes by 3M Company | Die Cutting | Kiss Cutting

3M is a company with diverse product lines. They manufacture a variety of different tapes, thermally conductive tapes, VHB Tapes, and more. Many of their tapes are catered towards electronic markets, as handheld devices become a commonplace item in all of our lives....

Die-Cut Silicone Products- Gaskets, Thermal Pads, Insulators, Absorbers

At NEDC, we would be remiss to not mention most of our products revolve around silicone-based materials. As a result, products that we offer a lot of die-cut silicone products. Out of our 5 core products, 4 are normally silicone based. In this post, we picked out 4...

Broadband Absorber- Eccosorb MCS

At NEDC, we cut many high-performing materials. One common material that we see is ECCOSORB. However, one of the more common ECCOSORB products NEDC sees is ECCOSORB MCS. This broadband RF microwave absorbing material is widely used in many industries across...

Gaskets, Thermal Pads, Absorbers, Epoxy Films

Like many people, I have pet-peeves. One of my small pet-peeves is when a company says “We are a one-stop shop” Well, if that were true a customer could literally just drop a BOM on your lap and expect that entire product assembled in a quoted lead-time. While there...

NEDC Prototyping Department

We often hear from the customers we work with, that our parts are the last thing people think of when completing a project. These parts can range from thermal interface materials that provide a stick-in-place solution, heat-dissipating solution, or a left-out gasket...

Kiss Cut Die Cut Parts

Nowadays everyone is trying to do everything faster. Make coffee faster, make cars fasters, make the computer that I am typing on faster. Some feedback that we often get from customers is, “These parts are so small, or so awkwardly shaped that removing the liner from...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

Can you use a Thermal Pad/Gap Pad more than Once?

My blogs largely originated from the various questions I have gotten from customers over the years. This includes the most popular ones. One question I realized I get an awful lot is : “Are Gap Pads Reusable?” Heres my short answer, “It depends, but I wouldn’t ever”....

Die-Cutting vs Laser Cutting, Epoxy Preforms: Part 2

I had a customer call the other day, saying he heard that laser cutting was better than die-cutting for frozen epoxy preforms. Heres the thought I had in my head “Why does this keep coming up!?” Heres my thought, and then I’m going dive into every advantage, and...

Super-Soft Silicone Rubber Gaskets | Tight-Tolerance/High-Temperature

At NEDC, Custom Silicone Rubber Gaskets are a common product we sell. Included in that category are the Super-Soft Silicone Rubber Gaskets that are available. When I think soft gaskets, typically below 40A durometer would be considered soft. However, when I think of...