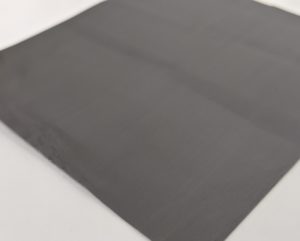

pgs thermal graphite sheet

Thermal management is a core competency at NEDC. One of the core products we die-cut is graphite-based thermal interface material. Panasonic has a line that features incredible thermal performance! Panasonics PGS(Pyrolytic Highly Oriented Graphite Sheet) Thermal Graphite Pads feature ultra high thermal conductivity, and low thermal resistance.

Properties/Availability of PGS Thermal Graphite Sheets

PGS features thermal conductivity of 700 to 1950 W/m-K. These materials are made up of a layered internal structure. This material is made up of artificial graphite that allows for the material to have incredible thermal conductivity. PGS is applied to heat-sources mechanically, or through adhesive tapes. It spreads the heat in the A-B direction to rid the package of heat. It can be used as an EMI shielding solution as well. The graphite sheets themselves have high heat resistance, withstanding 752°F. These graphite sheets are lightweight, bendable, and easily cut into shapes. These products are free of silicone. In addition, PGS it is RoHS/REACH Compliant. “EYG” stands for PGS Graphite Sheet. There are 3 configurations available.

Configurations Available Elastomer, Adhesive backing, PGS Only

-Elastomer(SSM)

The elastomer version is electrically isolating with a high volume resistivity.

-Tape(adhesives available are thin- ranging from 30µm to 6µm depending on type chosen.)

-PGS only(this is with no adhesive)

Thicknesses available for the PGS material :

.10mm(100µm), .07mm(70µm), .050mm(50µm), .040mm(40µm), .025mm(25µm), .017mm(17µm), and .010mm(10µm).

More Information

Naturally, different sheet sizes of these materials are available, and vary with configuration chosen. NEDC die-cuts or otherwise converts these parts into finished custom shapes. For more information regarding PGS Thermal Graphite, or you have an application that you feel could utilize it please contact sales@nedc.com.