RF/Microwave Absorbers

Microwave Absorbers

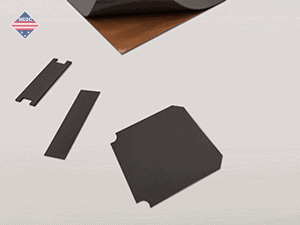

NEDC manufactures RF/Microwave absorbers into custom shapes through die-cutting, and waterjet cutting. Microwave absorbers have been used in military applications since their inception. However, more and more microwave absorbers are used in commercial applications. Applications such as computers, consumer electronics, network servers, and wireless antenna systems are common with microwave absorbers.

What are Microwave Absorbers?

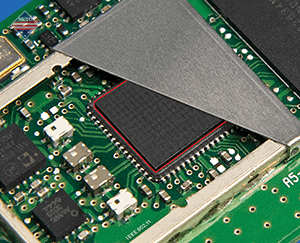

Oftentimes electronics can cause cavity resonances inside of electronic enclosures. Different types of microwave absorbers can be employed to attenuate the signal. The problem with normal EMI gaskets is they can actually exacerbate the problem by creating an additional conductive surface. This contains the issue within the cavity. Microwave Absorbers function by eliminating cavity resonances through lossy magnetic materials. Magnetically loaded elastomers are most seen by NEDC. Oftentimes electrical engineers will pick and place the microwave absorbers along the enclosure and then test the device. This is usually preferable to the time-consuming and complex nature of selecting a material by modeling.

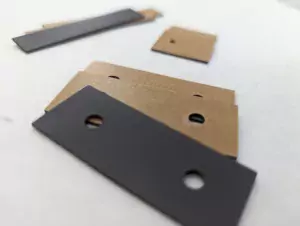

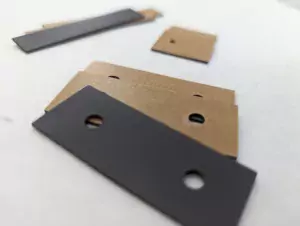

eccosorb gds, die-cut

eccosorb gds, die-cut

What type of Microwave Absorbers are available?

There are a few different considerations when reviewing the different types of absorbers available. There is frequency ranges, elastomers, and differently loaded materials.

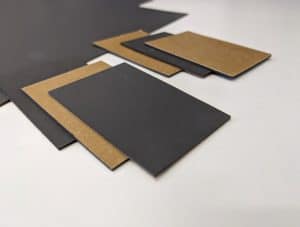

Dielectrically Loaded Materials

Dielectrically Loaded materials are typically foam materials coated with carbon. These foams are open-cell elastomers that can be made up of multiple layers. Obviously these foams are much thicker than their magnetically loaded elastomer counterparts. They range from .125”(3.2mm) to 2.00”(5.08mm) in thickness. This is a drawback with these foams. At .125”(3.2mm) being the thinnest available size can become a concern. With smaller and smaller packages coming to market size matters.

Magnetically Loaded Materials

NEDC commonly deals with elastomeric like absorbing materials. These materials are typically magnetically loaded with iron-based fillers. Different loading levels of the ferrous fillers affect the level of attenuation. Manufacturers design different absorber materials to withstand different environments. Oftentimes silicone rubber is the binder material, but other materials such as nitrile, neoprene, and urethane can be used. However for NEDC, silicone-based elastomers are still the most commonly seen. This is because silicone offers a great balance of temperature range, availability, Different manufacturers offer different options for different applications including high-temperature, different frequency requirements, and assembly options. NEDC cuts magnetically loaded absorbers as thin as .010’’ to as thick as .250’’.

Broadband Absorbers

Broadband is the largest category of microwave absorbers. These products operate over a bigger frequency spectrum. Broadband absorbers are much more available. For that reason, NEDC deals with mostly broadband microwave absorbers. They offer a great price point that ultimately offers great value for most applications.

absorber die-cut

Narrowband Absorbers

It is good to keep in mind that while broadband absorbers are more available, narrowband absorbers exist. These narrowband absorbers absorb at a specific frequency. Custom thicknesses, and formulations can help address more narrow frequencies that may need to be attenuated. Many different manufacturers offer microwave absorbers. Finding the right one for your application may take time, but there are many options available.

Manufacturers of Microwave Absorbers

- Laird

- 3M Company

- Mast Technologies

- 3G Shielding

- Cuming Microwave

Cutting Methods/Application Notes on Microwave Absorbers

NEDC die-cuts and waterjet cuts these materials into unique shapes. Typically, absorbers are placed in enclosures two ways. The first is through the use of RTV(room-temperature vulcanizing) adhesives. These RTVs usually take time to cure, and are a bit more labor intensive. The second is through the use of tape. Most absorbers are available with tape backing to enable easy placement of the absorbers onto different surfaces. However, it is good to keep in mind the surface the absorber is being placed on when choosing either method. When using either method of application, a properly cleaned surface, and following the manufacturers datasheet is critical.

For more information on RF/microwave absorbers, please contact sales@nedc.com.

RF Absorbers Blog

EMI/RFI Bulb/Hollow Gaskets – The Softest EMI/RFI Gasket

At NEDC, we mostly die-cut, knife-cut, or waterjet cut gaskets. However, we do also fabricate, glue, or bond together some gaskets. Why do we do this? The short answer is because we cannot die cut, or waterjet cut them. However, sometimes it's also for performance...

Previous Posts

Tips/Tricks to Avoid Supply Chain Disruptions | Custom Die-Cutters

In this supply chain taxed environment, I thought I’d write a blog about...

Knife-Cutting | New Capabilities at New England Die Cutting

Before the close of the 2022 year, NEDC bought a knife-cutting machine....

Eccosorb GDS | Broadband Absorber | Custom Die-Cut

NEDC die-cut RF absorbers all the time. In one blog, we discussed...

Microwave Absorbers

NEDC deals with countless materials that make it one of the most diverse converters in the aerospace, military, and medical industries. Microwave absorbers are one material that NEDC deals with on a daily basis. As the world becomes more electronically oriented, the...

Gap Pad EMI 1.0

In the converting industry we deal with a lot of materials. When you deal with materials ranging from 1 mil Mylar A to modified epoxy adhesive films, you gain a peculiar affinity for materials that stand out from the rest. Recently, I was introduced to an especially...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

Double Coated Tape 3M 9731- Acrylic/Silicone

We are an authorized 3M Converter at NEDC. As a result, we work with many of their tape products. These include VHB Tapes, EMI Shielding Tapes, Transfer Tapes, and many others. One of the tapes we work with often is 3M 9731 Double Coated Tape. This tape has the great...

Sil-Pad 900S Thermal Pad | Thin Thermal Pad | Custom Die Cut Shapes

NEDC has been die-cutting thermal pads since its inception in 1982. One of the more popular products Sil-Pad 900S by Henkel’s Bergquist. It is one of the most commonly die-cut materials NEDC converts. This product is part of the Sil-Pad family, featuring great thermal...

Silicone Gaskets, Pads- Silicone Foam, Sponge, Solid, EMI/RFI Shielding

At NEDC, we offer an incredibly wide range of materials. High performing materials such as silicone rubber is one of them. The reason for this is because silicone has countless incredible properties. These include great electrical properties, high & low...