Thermal Gap Filling Pads, Thermally Conductive Pads

Thermal Gap Pads, Thermal Tapes, Sil-Pads, Phase Change Thermal Pads, Thermally Conductive Tapes

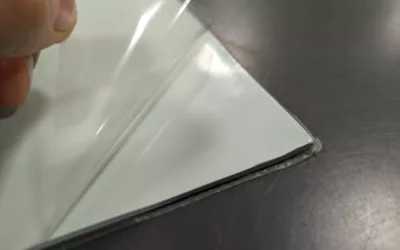

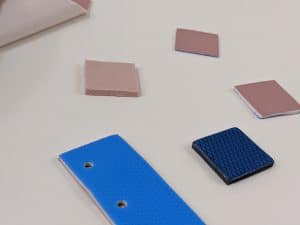

Thermal Management is becoming an increasingly important part of application design. Luckily Henkels’ Bergquist offers TIMs(Thermal Interface Materials) to allow for management of thermal issues. NEDC die-cuts thermal interface materials into finished parts that are called thermal pads. These thermal pads come in many forms as there are many applications. There are really two groups of pads with an incredible amount of overlap in between. There are Gap Filling Pads that provide thermal conductivity in the absence of a lot of pressure- these pads tend to be thicker .015” -.250”. On the other hand, there are thin thermal pads that usually utilize pressure such as clips or screws to provide sustainable pressure to allow for lowering thermal impedance. These thermal pads usually range from .030” to .005”.

There are a number of names we hear thermal pads called:

-Heat Transfer Pads -Thermal Gap Fillers

-Thermal Interface Pads -Thermally Conductive Pads

-Thermally Conductive Insulators -Thermal Gel Pad

Gap Filling Pads/Thermal Gap Filler Pads

Thermal Gap Pads

Gap Pad® is a gap filler used between electronics and heat sinks as a thermal interface. The benefit of Gap Pad is that it conforms to the different surfaces and textures that may be present in electronic applications. Gap Pad may be used to fill air gaps, inconsistent surface topography, and other odd surfaces. The benefits it provides are:

-

Low-stress vibration dampening

These gap filling pads can dampen vibrations due to the softness and durability of the pads.

-

Elimination of air gaps to reduce thermal resistance

Elimination of air-gaps is a function of conformability, pressure, and softness. Gap Pad® is adept at providing a solution that can help to eliminate air-gaps, reducing heat in the end application.

-

High conformability to reduce interfacial resistance

Different topologies in the application can create interfacial resistance causing air-gaps. Having good conformability, and low modulus can allow the Gap Filling Pad conform to the surface easier.

There are a significant amount of Gap Pad® offerings for different applications. This allows for a good mix of performance, price point, and assembly use.

- Gap Pad® VO Ultra Soft (VOUS), GPVOUS aka GAP PAD TGP 1000VOUS, Sil Pad 900S Reinforced, 1 W/m-K

- Gap Pad® VO Soft (VOS), GPVOS aka GAP PAD TGP 800VOS, Sil-Pad 900S Reinforced, 0.8 W/m-K

- Gap Pad® 1500S30, GP1500S30 aka GAP PAD TGP 1300, fiberglass reinforced, 1.5 W/m-K

- Gap Pad® 1500, GP1500 aka GAP PAD TGP 1500, no reinforcement, 1.5 W/m-K

- Gap Pad® 2000S40, GP2000S40 aka GAP PAD TGP 2000, fiberglass reinforced, 2 W/m-K

- Gap Pad® 5000S35, GP5000S35 aka GAP PAD TGP 5000, fiberglass reinforced 5 W/m-K

- Gap Pad® 2200SF, GP2200SF aka GAP PAD TGP 2200SF, fiberglass reinforced, 2.0 W/m-K

- Gap Pad® HC5.0, GPHC5.0 aka GAP PAD TGP HC5000, fiberglass reinforced, 5 W/m-K

- Gap Pad® HC3.0, GPHC3.0, aka GAP PAD TGP HC3000, fiberglass reinforced, 3 W/m-K

- Gap Pad® 3000S30, GP3000S30, aka GAP PAD TGP 3000, fiberglass reinforced, 3 W/m-K

- Gap Pad® 7000ULM, GP7000ULM aka GAP PAD TGP 7000ULM – no reinforcement, 7 W/m-K

- Gap Pad® 3500ULM, GP3500ULM aka GAP PAD TGP 3500ULM – fiberglass reinforced/ option without fiberglass as well, 3 W/m-K

Usually Gap Pad® is not available with PSA. However, Gap Pad® VOUS, VOS, VO are all available with PSA(Pressure-Sensitive Adhesive). Although, inherent tack is available on most Gap Pad® products to aid in assembly. It is important to note that adhesives may further impede the thermal pathway of the material. NEDC die-cuts Gap Pad® with conventional die-cutting machines through steel-rule dies.

How much to Compress Gap Pads?

Over the years, I’ve seen quite a bit of thermal pad discussion. A lot of it centers around how thermal performance is not good with thick Gap Pads, or low W/m-K thermal conductivity Gap Pads. However, one thing I plead customers to remember is: THIN TO WIN. I say this for two reasons:

A. The more you compress a Gap Pad, the less distance is between the power producing device, and the heat sink. However, be careful not to over compress because if you do, you will extrude the pad, and it loses its integrity, and thermal performance will ultimately suffer.

B. Compressing the Gap Pad even moderate amounts will dramatically improve thermal performance. With that said, aiming for a target of 30% to 50% compression of nominal thickness would be a good goal. For example, if the Gap Pad is .125” thick, aiming for a compressed thickness of .063” would be a good start.

Is there a difference in Gap Pads softness?

While I don’t believe in “experts”, I think I’m as close as your going get when it comes to what is available in the Thermal Gap Pad world. It is funny to me, when I see the different superlatives of softness in Gap Pads.

We see:

Uber-Soft, Very-Soft, Ultra-Soft, Extremely-Soft

I can tell you, this is just marketing. HOWEVER, thermal pads softness is very important. The numbers you should be looking at are Hardness(durometer), and Modulus. These two numbers in conjuntion tell you how conformable the material really is.

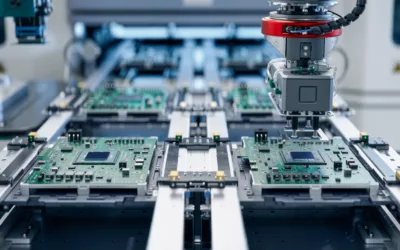

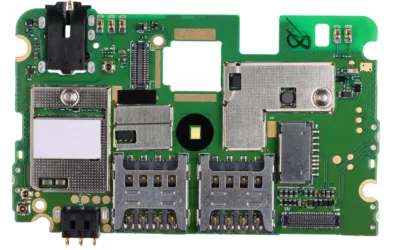

Applications that Utilize Thermal Interface Pads

These applications could utilize any of the types of thermal pads, we manufacture.

-Computers/Peripherals(Computer Monitors/Screens)

-Avonic navigation systems

-Power Conversion such as DC/DC, buck(step-down), buck/boost, boost(step-up) converters

-Consumer Electronics such as phones, tablets

gpvous, gp1500, gphc5.0

Sil Pad®

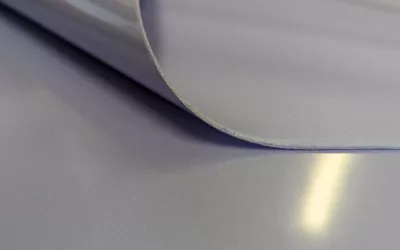

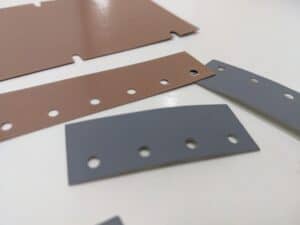

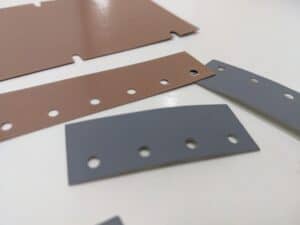

Sil Pad® is a thermally conductive insulator that has a wide reaching use in different applications. Sil Pad® is usually provided on the thinner side. These pads require higher pressure than their gap filling pads mentioned above. The benefits of Sil Pad® include:

-

Great thermal performance

These thermal pads are designed for great thermal performance. It is important to keep in mind that while thermal conductivity is an important metric, its not the only metric. Thermal impedence, thickness, hardness are all important qualities to look at.

-

Eliminates clean-up from thermal greases

Clean-up from greases can create an extraordinary mess. Having a neat, clean solution for your thermal issue can be incredibly useful.

-

Sil Pad® has an efficient cost structure

Sil Pad® is able to offer great performance, ease of assembly, good reliability and a great cost/benefit ratio.

Sil Pad® has a long list of different products, all of these different types of Sil Pad® have different qualities and benefits.

The first thing to know when reviewing the types of Sil-Pad available is there is two types of reinforcement. There is film reinforcement, and there is also a fiberglass reinforcement. In Sil-Pads, theres fiberglass, and there is polyimide reinforcement. You will notice thermal pads reinforced with Fiberglass suffer a little bit on dielectric performance compared to polyimide film reinforced versions.

- Sil Pad® 400, SP400 aka SIL PAD TSP 900- Fiberglass Reinforcement

- Sil Pad® 800, SP800 aka SIL PAD TSP 1600-Fiberglass Reinforcement

- Sil Pad® 980, SP980 aka SIL PAD TSP 1680-Fiberglass Reinforcement

- Sil Pad® A1500, SPA1500 aka SIL PAD TSP A2000-Fiberglass Reinforcement

- Sil Pad® 1200, SP1200 aka SIL PAD TSP 1800-Fiberglass Reinforcement

- Sil Pad® 2000, SP2000 aka SIL PAD TSP 3500-Fiberglass Reinforcement

- Sil Pad® A2000, SPA2000 aka SIL PAD TSP A3000-Fiberglass Reinforcement

- Sil Pad® K6, SPK6, aka SIL PAD TSP K1100-Polyimide Reinforcement

- Sil Pad® K10, SPK10 aka SIL PAD TSP K1300-Polyimide Reinforcement

NEDC die-cuts or otherwise converts Sil Pad® products into finished thermal pads through waterjet cutting or die-cutting. Sil Pad® is usually available with pressure-sensitive adhesive depending on the specific pad. In addition, some are available with tape on both sides of the pad.

sil-pad configurations

sil-pad configurations

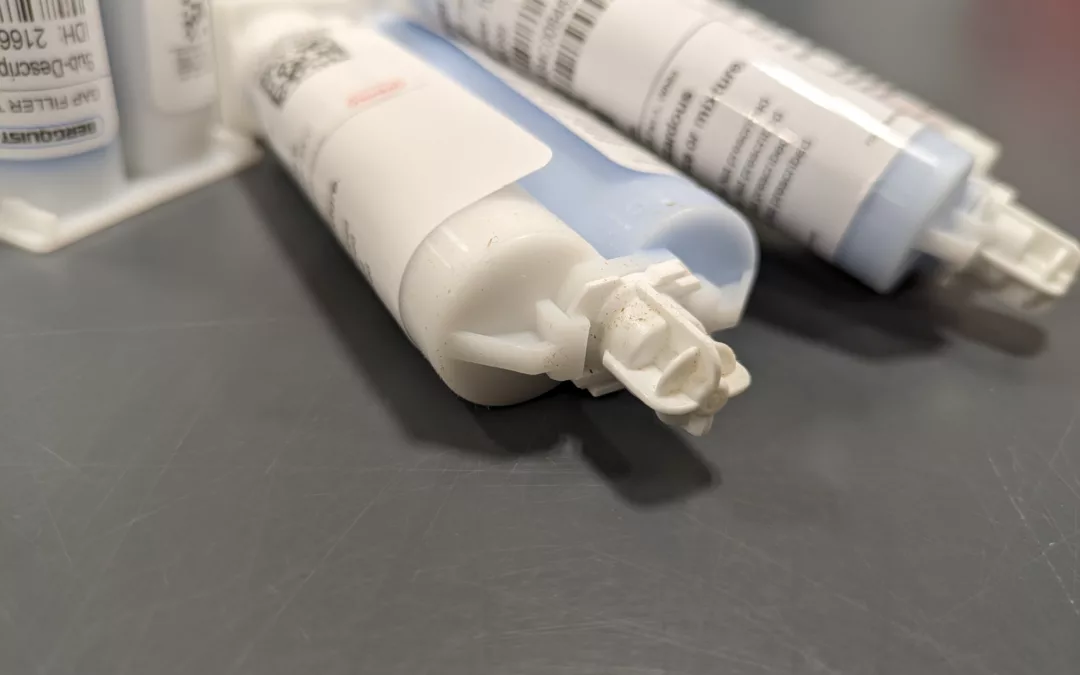

Phase-Change Thermal Pads

Phase-Change materials are heated into place during the assembly. These thermally conductive materials provide similar benefits to thermally conductive pads such as Sil Pad. Hi-Flow is a phase change material provided by Henkels’ Bergquist. Hi-Flow is useful in applications requiring a replacement for grease as a thermal interface between CPU or power devices and a heat sink. The benefits of Hi-Flow material include:

-

A replacement to grease, with the benefit of saving time and money

As discussed with other thermal pads, replacing grease is a principle interest. This is because thermal grease can be difficult to apply properly, and difficult to clean up.

-

Easy handling, not tacky at room temperature

Tackiness at room temperature can be difficult to handle. Having a neat, clean solution that is easy to apply to the application before the material activates can be very convenient.

A few Hi-Flow products include:

- Hi-Flow® 105, HF105 aka HI FLOW THF 900

- Hi-Flow® 225F-AC, HF225F-AC aka HI FLOW THF 1000F-AC

- Hi Flow® 225U, HF225U aka HI FLOW THF 1000U

- Hi-Flow® 650P, HF650P aka HI FLOW THF 1500P

- Hi-Flow® 625, HF625 aka HI FLOW THF 500

Hi-Flow® is available with or without pressure sensitive adhesive on the back. Thicknesses of different Hi-Flow® products range from .005” to .015”. NEDC die-cuts Hi-Flow® through conventional die-cutting equipment.

Thermally Conductive Tape

These thermally conductive tapes are essentially materials that are filled with thermally conductive fillers with tape on both sides to aid in assembly. One commonly chosen material in industry is Bond-Ply®. Bond-Ply® by Henkels’ Bergquist are double sided tapes with different reinforcements. Some of the benefits may seem obvious, but assembly can present a challenge – especially in custom cut thermal pads.

-

Replacement to heat cured adhesives

Heat cured adhesives need certain setups that can be costly depending on the application. Having an alternative that is easy to assemble at room temperature can provided a great cost/benefit ratio.

-

Replacement to screw/clip mounting

As we have discussed the challenges of thermal greases, even uses clips and screws can present challenges in certain applications.

Some common Bond-Ply products are below:

- Bond-Ply 100, BP100 aka BOND PLY TBP 850

- Bond-Ply 800, BP800 aka BOND PLY TBP 800

- Bond-Ply 400, BP400 aka BOND PLY TBP 400

We are often asked how we cut thermal pads. This question usually comes from someone using a exacto-knife, or scissors. While its true you can cut thermal pads that way- die cutting or waterjet cutting is the best way to cut thermal interface pads. NEDC offers die-cutting (converting) services for thermal pad materials. For more information on Hi-Flow materials please visit Henkels’ website.

Tips for Selecting which Type of Pad to Use

We usually look at thermal pads as pretty simple to work to choose. I would say, well there are a million choices, and a million different outcomes- I think the best results are usually yielded by:

1. Think “Thin to Win”

The thinner the pad is, the better the thermal transfer between the heat generating component and the heat sink, or heat dispersing medium. You have to remember- heat does not like to travel. If it can go .001” inches less, it will want to do that. The goal should always be- make the thermal interface line as thin as possible. Less material means less travelling.

2. Pressure is your friend

Not all thermal pads are designed to accept enormous pressure, but all thermal pads do better with pressure. For example, most Thermal Gap Filler Pads are subject to up to 40% compression to yield the best results. Pressure tools can include:

- Clips for Mounting

- Screws for Mounting

- Weight on top of the pad, such as electronic components- or heavy heat sinks.

Surface Contact comes in a number of forms- but the end goal of the pad is to make as much contact as possible.

3. Bulk Thermal Conductivity balanced with Cost

Many of the thermal conductive materials are imparted thermal conductivity through heavy/expensive metals such as ceramic, diamond, aluminum nitride and other materials. These fillers bring up the cost of the total pad- but also help increase thermal conductivity. We’ve seen pads with significantly bulk thermal conductivity, outperform the highest thermal conductive pads on the market by a lot. I’d use thermal conductivity to help sort- but I’d view it as one of the last metrics to sort by.

Why do Thermal Gap Pads, or Other Thermal Pads have Fiberglass/Kapton Reinforcement?

Thermal Gap Pads are naturally like “putty”. This means that without some type of reinforcement most pads would fall apart in your hands. Its not a coincidence that only one thermal pad has no reinforcement (Gap Pad TGP 1500). This is due to a unique formulation. In addition, these Gap Pads need cut-through resistance, and handling strength because without that, they would be feeble in many of the applications they are entering.

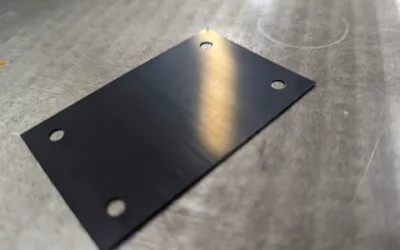

Graphite Thermal Pads

-Graphite Thermal Pads, these pads are thermally, and electrically conductive

Thermal Pads Blog

Thermal Gap Filler | NEDC distributes TGF 3600/GF3500S35 | Information

At NEDC, some say we are experts in thermal gap pads. We are also experts in liquid gap filler materials. So much in fact, we actually distribute both. One of the materials we like a lot, and will be highlighted in an upcoming video is TGF 3600, or...

Previous Posts

NEDC Launches Video Demonstrating How Thermal Pads Work!

<iframe width="1519" height="526"...

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of...

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for...

HPMS Graphite | Flexible Graphite | Custom Die-Cut Parts

At NEDC, we like to think we are experts in thermal interface materials. Flexible graphite material is an excellent thermally conductive material. In fact, I see a lot of thermal interface pads going in this direction due to its great thermal conductivity, & low...

T-Global Technology | Thermal Gap Pads | Thick, Thin, High W/m-K

At NEDC, thermal pads are our specialty. Our manufacturing site is in Methuen, MA. Across the pond, in the United Kingdom, there is a reputable thermal pad manufacturer. This manufacturer is called T-Global Technology. They make a number of thermal interface...

Nickel Coated Aluminum Gaskets | EMI Gaskets | Corrosion Resistant Gaskets

EMI Gaskets are not a new technology. They have been around for the last 60 years. However, once in a while a new technology emerges for a different type of foam, or a different type of orientation of materials. Over the last few years, a new type of particle has...

Applications: Scanner, PDDs, Analyzers – Gaskets, Pads, Thermal Pads

At NEDC, we manufacture an incredible array of applications. In today's blog, I thought I’d talk about something we’ve all interacted with at some point. In today's world, we are trying to have the data at our fingerprints all the time. Some of these mobile devices...

Why Commercial EMI/RFI Gasketing | Custom Die-Cut EMI Gaskets

At NEDC, we sell gaskets, lots of them. I would love nothing better than to sell a fully loaded pure silver gasket. Love it. However, I’ll be honest, I don’t think that's necessary most times. When customers have all the money in the world to spend, sometimes I wish...

LOCTITE® Thermstrate 2000 aka TCF 1000AL | Die-Cutting/Converting

At this point, I’ve written 250 blogs on this website- I know, I am even like, how much of a thermal pad geek am I? Why did I ask this question? I was curious if I have written a blog about LOCTITE® Thermstate 2000 Phase Change material. At one point, we had written a...

Can you use a Thermal Pad/Gap Pad more than Once?

My blogs largely originated from the various questions I have gotten from customers over the years. This includes the most popular ones. One question I realized I get an awful lot is : “Are Gap Pads Reusable?” Heres my short answer, “It depends, but I wouldn’t ever”....

TGON 800 Series | 805, 810, 820 | Electrically Conductive Thermal Pad

The TIM world is like the big bang.. It moves, and expands faster than ever. The reasoning for this is the fact that clock rates continue to expand and move even more rapidly. In this world, graphite is a TIM of choice because of a few features. Its available in thin...

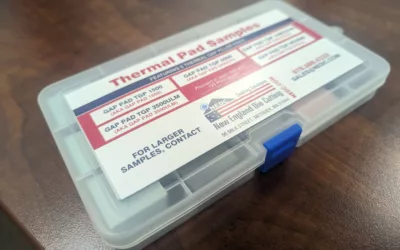

Thermal Pad Tackle Box | Sales Tool for Testing/Sampling

At NEDC, we are all about thermal. We enjoy making new sales tools to help customers design thermal interface pads into their applications. Why use this Sales Tool? This thermal pad tackle box allows the user to try different thermal pads. In this kit, we have 5...

Thermal Pad vs. Thermal Grease/Mica

One common question I hear engineers ask about is if it's better to have Mica/Grease or Sil-Pad products. Obviously, I’m partial to this, but I wanted to give some thoughts I had about Mica/Grease, and why I think it has its place, but why I think in a manufacturing...

TFLEX 600 | High-Compliance Thermal Pads | Low-Stress

NEDC manufactures thermal pads for many different customers. The thing I love about thermal pads, there is so many of them. Each one has different properties, and has its own fit for applications. Properties of TFLEX 600 Thermal Pad TFLEX 600 is a boron nitride...

Engineering Note: Hole Diameters: How low can you go?

At NEDC, cutting gaskets is what we do. Gaskets typically have holes in them to provide room for screws or bolts to go through them in order to provide pressure, and then for that reason, also to provide compression for the gasket to seat/seal properly. How small is...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of cooking.

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for customers to buy. For that reason, NEDC has many frozen films in stock. These include: Ablefilm 5025E Ablefilm 561K Ablefilm CF3350 Ablefilm 566K And others. We wanted to just get it out there on...

Pure EMI Silver Gaskets, Are They Needed?

Customers ask me for material selection recommendations all the time. One way I believe I build trust with clients is, I don’t upsell things I don’t need to. Customers literally once a week call and say, I NEED VITON! Oftentimes my response is “Hey, I’ll sell you...