Epoxy Films, Adhesive Preforms

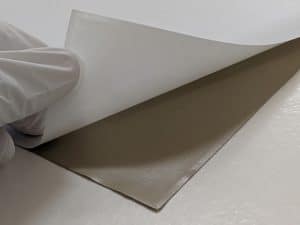

Epoxy Adhesive Preforms define custom parts that are cut out of an adhesive film material that can come either thermally conductive, or electrically conductive. However, oftentimes they come as both. In addition, some of these films are supported by carriers. These include fiberglass or polyimide films to ease in handling and assembly. Epoxy preforms offer an alternative to conductive thermal pastes that can be difficult for assembly.

Benefits of Epoxy Films

Cleanliness and Cleanup

With epoxy films, since these films can be preformed to shape it minimizes the amount of post-cleaning that is required to be done before, and after bonding is completed.

Consistency of Application

Conductive Thermal Pastes can be inconsistent for the sole reason of how its applied. Depending on who/how it is applied. On the other hand premade epoxy preforms are made the same way every-time. The thickness, cut-outs, and tolerances of the preform can all be held to +/- .002” in some cases.

No Mixing Time

Since Epoxy Preforms are 1 part pre-cut parts, there is no need to mix anything unlike some of the conductive thermal pastes available.

Overall, epoxy preform film materials add a lot of consistency and can lower cost per unit of production.

Benefits/Drawback of Supported Epoxy Films

Benefits:

1. Handling

I cannot begin to overstate how much easier handling is with a carrier. Unsupported films can fall apart in your hands because of the lack of support. Cutting should be done on the liners, or with the support of something at all times.

Drawbacks:

1. Cutting

Cutting can be a bit more of a challenge with a supported epoxy film. The reason for this is laser cutting is the preferred method of cutting for complex epoxy shapes. Polyimide or fiberglass can make the cut a little rougher or harder to cut through.

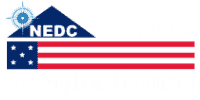

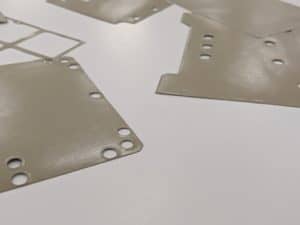

Epoxy Preforms

The material being preformed allows allows for more uniform bond lines and consistent application of the adhesive across the assembly. When there is many cut-outs and close tolerancing using automated machines can offer an incredible amount of consistency. Applications such as bonding to heat-sinks are common for these films. These epoxy films can be laser-cut or die-cut.

Availability of Epoxy Film Materials

Henkel manufactures a number of assembly film options that may be a fit for different applications that require epoxy preforms:

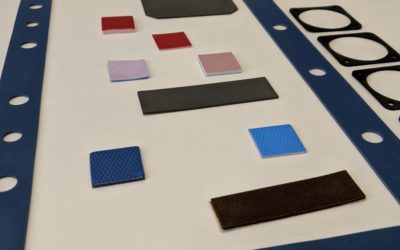

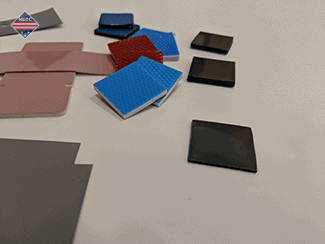

Electrically/Thermally Conductive Films

ECF561E ™

CF3350 ™

ECF550 ™

ECF563 ™

Thermally Conductive Films

5020K ™

561K ™

566K ™

563K ™

506 ™

Epoxy Film Preforms

It is wise to consulate about epoxy film sheet sizes before determining sizes of preforms. With these materials tightly controlled performance characteristics and thickness tolerances availability of size can be tricky.

Storage

Storage is an important consideration with these films. Oftentimes these films are required to be stored at temperatures at freezing or sub-freezing in order to maximize the shelf life. This includes when shipping these materials that they are shipped at temperatures required by their datasheets. Our team generally refers to two different types of ice. There is Blue Ice and there is Dry Ice. Blue Ice keeps the package at around 30-45°F, and Dry Ice keeps the package sub-zero fahrenheit.

Converting

At NEDC, we laser-cut or die-cut epoxy preforms to many different custom shapes for our customers. Epoxy Preforms are usually very intricate with many twists, and turns in the cuts. With these challenges, choosing between die-cutting or laser cutting is a tough choice sometimes.

The delineation between laser-cutting or die cutting is often stratified by a number of factors including:

-Complexity of the cut-outs

-How many preforms are being manufactured

-How big/small the preform is

-Tolerance requirements(recommended +/- .003’’ for cutouts, +/- .005’’ for locations)*

If you have an application that you believe could utilize preforms or assembly films, please contact sales@nedc.com.

Epoxy Films Blog

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for customers to buy. For that reason, NEDC has many frozen films in stock. These include: Ablefilm 5025E Ablefilm 561K Ablefilm CF3350 Ablefilm 566K And others. We wanted to just get it out there on...

Previous Posts

Die-Cutting vs Laser Cutting, Epoxy Preforms: Part 2

I had a customer call the other day, saying he heard that laser cutting...

Tips/Tricks to Avoid Supply Chain Disruptions | Custom Die-Cutters

In this supply chain taxed environment, I thought I’d write a blog about...

Knife-Cutting | New Capabilities at New England Die Cutting

Before the close of the 2022 year, NEDC bought a knife-cutting machine....

Developments/Challenges at NEDC in 2022

At NEDC, we closed a strong 2022. However, it was not all sunshine, and rainbows. It was quite the opposite. We faced a number of challenges. There weren't only bad things, there was a few silver linings as well. Challenges/New Developments at NEDC in 2022 ...

Henkels’ CF3350 Epoxy Film Preforms | Laser-Cutting/Die-Cutting

At NEDC, we cut epoxy preforms films regularly through die-cutting and laser-cutting. Oftentimes, our customers utilize a preform material they have used before. Ablefilm 5025E is a common material we see customers utilize. However, we also see customers utilize...

Laser-Cutting Epoxy Preforms Vs. Die Cutting | Some Thoughts

At NEDC, we are a build to print vendor. In my few years here,(7 if we're counting- please don’t count though), I have seen customers put some funny things on their prints that imply, or request us to cut a certain way or bag a certain way.. Oftentimes driving up cost...

Rogers’ Thermabond – Thermally Conductive Adhesive Preforms

At NEDC, we cut a lot of adhesive preform products into finished cut parts. One of the more common adhesive products that NEDC cuts is Thermabond® Silicone Electronic Adhesive products by Rogers Corporation. Properties of Thermabond Adhesive Preforms A common demand...

Die Cut Gaskets vs. Laser Cut Gaskets vs. Waterjet Cut Gaskets

At NEDC we operate many pieces of cutting machinery. We operate state of the art conventional die cutting machines, laser cutting machines, and waterjet cutting machines. In this blog post, we thought we would delineate the differences between all of these machines so...

Rogers COOLSPAN® TECA, Laser-Cutting

NEDC laser-cuts many materials with its laser-cutting machines. One of the most frequently cut materials at NEDC is frozen epoxy films. Many of these film materials offer thermal and/or electrical conductivity. COOLSPAN® TECA from Rogers Corporation is a thermally and...

Custom Die Cutting

As I always say, every print is like meeting a new person. Similar to DNA, every print is unique to the material, shape, size, tolerance, and specifications. At NEDC, our business model is built around the idea that whatever design our customers come up with, if we...

Thermal, Thermal, Thermal

At NEDC our products are constantly evolving. As thermal management becomes a priority in ever smaller electronics, thermal management die-cut products become an even bigger part of our product line up. Some of our products include saving heat, but most of our...

Ablefilm® 5025E™ Preforms

At NEDC we die-cut and laser-cut many types of adhesives. One adhesive that stands apart is Ablefilm® 5025E™. This film is one of the most common converted at NEDC via laser-cutting or die-cutting. 5025E is an unsupported electrically/thermally conductive epoxy film...

Gaskets, Thermal Pads, Absorbers, Epoxy Films

Like many people, I have pet-peeves. One of my small pet-peeves is when a company says “We are a one-stop shop” Well, if that were true a customer could literally just drop a BOM on your lap and expect that entire product assembled in a quoted lead-time. While there...

Thermal Conductivity is Not Everything

One thing we commonly hear in the thermal management industry is “This has 5 w/m-k and that has 1 w/m-k, so this one with 5 w/m-k must be better.” We thought we would write a blog to discuss how oftentimes this thinking paints a poor picture of what the situation...

NEDC Prototyping Department

We often hear from the customers we work with, that our parts are the last thing people think of when completing a project. These parts can range from thermal interface materials that provide a stick-in-place solution, heat-dissipating solution, or a left-out gasket...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of cooking.

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for customers to buy. For that reason, NEDC has many frozen films in stock. These include: Ablefilm 5025E Ablefilm 561K Ablefilm CF3350 Ablefilm 566K And others. We wanted to just get it out there on...

Pure EMI Silver Gaskets, Are They Needed?

Customers ask me for material selection recommendations all the time. One way I believe I build trust with clients is, I don’t upsell things I don’t need to. Customers literally once a week call and say, I NEED VITON! Oftentimes my response is “Hey, I’ll sell you...