COOLSPAN® TECA Epoxy Film

NEDC laser-cuts many materials with its laser-cutting machines. One of the most frequently cut materials at NEDC is frozen epoxy films. Many of these film materials offer thermal and/or electrical conductivity. COOLSPAN® TECA from Rogers Corporation is a thermally and electrically conductive silver-filled frozen epoxy film that is used for permanent bonding of circuit boards to heatsinks.

What is COOLSPAN® TECA?

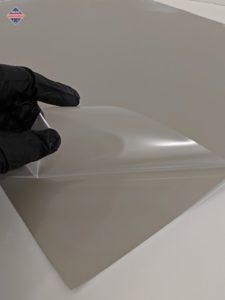

This thermosetting film is commonly laser-cut into epoxy preforms for customers to provide an ease of bond in their application. This adhesive-film allows for a consistent bond-line across the application. This compares to other adhesives that may cause air-gaps or otherwise inconsistent bonds that may ultimately not perform well. This clean, neat film cut into a preform can provide a clean solution to permanent bonds for RF module housings. These preforms can be especially helpful when many cut-outs, and features make for a crowded bond line. This film features a thermal conductivity of 6 W/m°C, and an extremely low volume resistivity of .00038 ohms-cm. This film features great chemical resistance, and fantastic high temperature performance. COOLSPAN® TECA is intended to be a permanent bond once bonded in the application. Ways of cutting COOLSPAN® TECA are numerous. However, NEDC has found that best results seem to come from die-cutting, and laser-cutting.

More Information- Availability/Shelf Life

This material has a 12 month shelf life from Date of Manufacture. COOLSPAN® TECA film is available in .002’’, and .004’’ in thickness. Sheets are held within +/- .0005’’ in order to ensure a uniform bond line. It comes in a number of sheet sizes, so it is best to inquire for bigger size preforms. COOLSPAN® TECA has a dull tan color. NEDC is a major supplier of laser-cut adhesive film products. For more information on COOLSPAN® TECA, or you believe you have an application that could utilize COOLSPAN® TECA film, please contact sales@nedc.com.