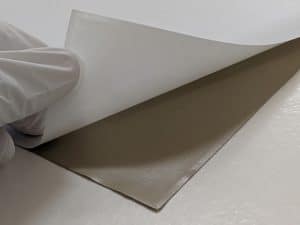

Ablefilm Sheet 5025e

Uses and Benefits of Ablefilm® 5025E™

Adhesive Films are used because of their inherent ability to control thickness, and cost per unit. The uses of 5025E™ is complemented by its benefits. The benefits of Ablefilm® 5025E™ include:

-Thin Uniform Bondline

-Providing EMI/RFI shielding

-Great thermal and electrical conductivity

-Quick cleanup/Easy of assembly

-Each preform is certified to MIL-STD-883, Method 5011

Availability of Ablefilm® 5025E™

These films are supplied in a neat format of sheeted goods. Sheets available depend on the thickness. This material is available in a few different thicknesses ranging from .002” to .006”. The thickness tolerance on this material is +/- .0005” below .003” and above is +/- .001”:

Cutting Options of Preforms

NEDC laser-cuts, and die-cuts Ablefilm® 5025E™ material. The shape of the preform is limited by the size of the sheet provided. NEDC oftentimes can hold tolerances as close as +/- .001’’-.002’’ on preforms of this material. In addition, NEDC commonly has stock of this material to sell full sheets, or completed epoxy preforms. Storage temperature of this film is 0° C. The color for this material is a dark tan. For more information on Ablefilm® 5025E™ or you believe you would have an application that 5025E™ would fit well in, please contact sales@nedc.com.