Electrical Insulators

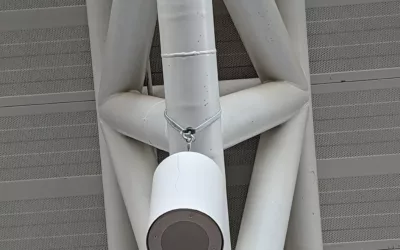

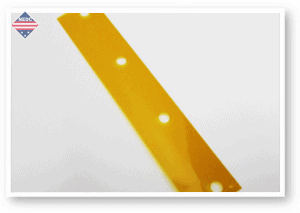

Kapton Insulator

Die-Cut Insulators were one of NEDC first products. This product line went along with gaskets as some of the first parts NEDC cut for customers. When NEDC first started, most electrical insulators were die-cut. However, with the new machinery that NEDC employees, waterjet, laser, and other machines also play a part.

Materials

Many of the materials used for electrical insulation are also used on our other products. In other words, gaskets, and thermal pads may also isolate an electrical current. As a result, materials including plastic, thermal interface pads, rubber, and paper like products all may have the ability to be electrically isolating.

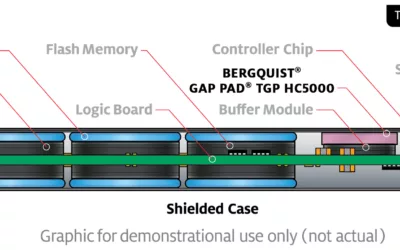

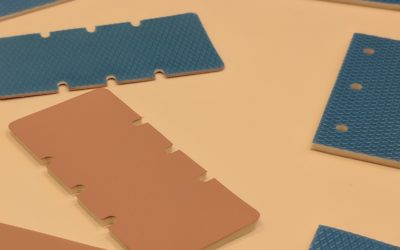

Thermal Pads

One of NEDCs core products are thermal pads. For that reason, its interesting that thermal pads oftentimes serve as electrical insulators. Products such as Sil Pad®, and Gap Pad®, are marketed because of their high volume resistivity making them ideal for electrical insulation while providing a thermal management solution.

Many Gap Pad® products offer electrically insulating properties. Gap Pad® products such as GPVOUS, GPVOS, GP5000S35, GPHC3.0, GPHC5.0 offer high levels of electrical insulating properties. This is in addition to their thermally conductive properties as well.

Many Sil-Pad® products offer electrically insulating properties. Sil Pad® products that are electrically isolating include Sil-Pad 900S, Sil-Pad 2000, Sil-Pad 400, and others.

Thin Plastics

Many thin plastics that NEDC cuts are electrical insulators. Materials like Kapton®, Mylar®, Lexan®, Formex®, G10/FR4 Epoxyglass all may serve as electrical insulators. These plastics can be converted into die-cut insulators.

Mylar® is a polyethylene terephthalate(PET) that is registered by DuPont. These materials usually come in thin films ranging from .002” to .014” in thickness. It is commonly used as an electrical insulator. MYLAR® A is the most common type. Mylar® MO is approved for Class B insulation.

Kapton® is a polyimide film that is registered by DuPont. This plastic can be certified to MIL-P-46112 Type 1, and ASTM D5213 Type 1 Item A. It usually comes in thin formats such as .0005” to .005” in thickness. Anything above this enters into the category of Cirlex®. Common applications include insulation blankets, and insulation tubing. There are a few different types of Kapton Film besides Kapton HN. These include Kapton® FN, Kapton® FWR, Kapton® GS, Kapton® MT+, and Kapton® RS.

Lexan® is a polycarbonate plastic that is oftentimes die-cut in film form. Lexan® plastic is a registered trademark by SABIC. Lexan® is extremely tough, but is formable. There are many different types. However, NEDC mainly die-cuts 8010, FR700, and others.

Formex® is a flame retardant polyproylene plastic. Formex® has excellent electrical properties. This plastic is fungus inert. There is GK-5, GK-10, GK-17, GK-30, GK-40, and GK-62. These plastics run from .005” in thickness to .062”.

Epoxyglass/G10/FR4 is a plastic like material that is really laminated glass with epoxy bonding it together. These materials are oftentimes used as electrical insulators. Most often NEDC die-cuts these materials, the thickness is below .015”. G10 is generally not thought of flame retardant. However, FR4 is flame retardant. MIL-I-24768 encompasses many different options. G10 being /2, and FR4 being /27. These materials are generally available .005”-many inches thick.

Rubber

At NEDC we cut many rubber materials to make gaskets. However, rubber materials can also sometimes serve as electrical insulators. For example, silicone rubber is a great electrical insulator that is commonly used in cables or wiring. Some other rubber materials used for electrical insulation include fluorosilicone, neoprene, EPDM, or urethane.

Silicone Rubber is commonly used as an electrical insulator. In fact, this material is probably the most commonly used material at NEDC. We use silicone rubber for gaskets, insulators, vibration dampening, and many other uses. Common certifications include A-A-59588, ZZR765, and others.

Fluorosilicone Rubber is another commonly used electrical insulator. However, it is not as commonly used as silicone because of its other qualities that tend to make it more expensive. Some specifications include MIL-R-25988, AMS-3329, and others.

Neoprene Rubber is a synthetic rubber also another commonly used electrical insulator. It is used in cable jacketing for wire and cable. It is often flame resistant.

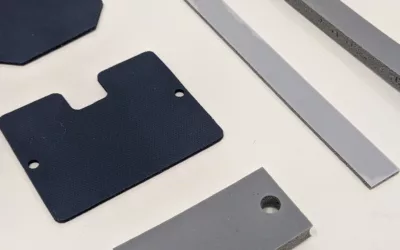

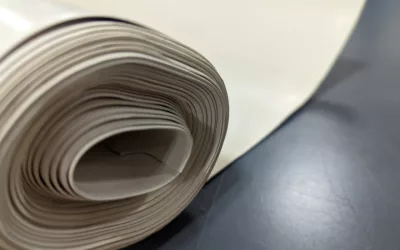

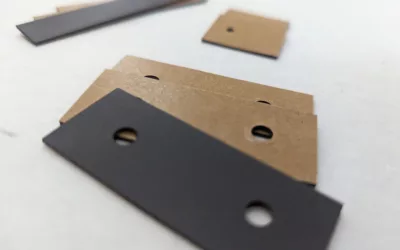

Paper like Products – Die Cut Insulators

Many paper like products serve as electrical insulators. Some common ones that NEDC sees are Nomex®, Fishpaper, Kraft Pulp, and others.

Nomex® is a aramid fiber paper. It has a high dielectric strength. This paper is used for The most common type of Nomex® is Nomex 410. Nomex 410 comes in a number of thicknesses ranging from .002” to .030”.

Fishpaper is an electrically insulating paper that is resistant to heat. It is an excellent insulator used in fuse tubes, and electronic devices. Thicknesses of fishpaper range from thin (.005”) to thicker (.030”). Specifications include MIL-I-495. It mostly comes in dark colors such as gray, or dark blue.

Electrical Qualities to look for with Die-Cut Insulators

Volume Resistivity

Volume Resistvity plays a huge part in die-cut insulators. The higher this number the better. A low number indicates the materials conductivity. This number indicates how much the insulator resists electric currents.

Dielectric Strength

Dielectric Strength is an important metric with die-cut insulators. It helps determine the quality of the insulator. It is defined as the maximum voltage required to produce dielectric breakdown through the material. All the materials above would register a high dielectric strength, for example.

Thermal Pad, Silicone, g10, Sponge

Conclusion

As with most materials NEDC provides, adhesive backing is available on certain products. Some common tapes we use from 3M are acrylic based 9485PC, 9472, 467MP, and 9469PC. For more information on electrical insulators, or you believe you have a project that could use a die-cut insulator, please contact sales@nedc.com.

Electrical Insulators Blog

NEDC Launches Video Demonstrating How Thermal Pads Work!

<iframe width="1519" height="526" src="https://www.youtube.com/embed/Z5l5bvd-4CE" title="How do Thermal Interface Pads/Thermal Gap Fillers Work? A Demo!" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope;...

Previous Posts

Thin Gasketing Options | .015”, & Below | High Performance Gaskets

Applications get smaller, and smaller everyday. As footprints of the...

T-Global Technology | Thermal Gap Pads | Thick, Thin, High W/m-K

At NEDC, thermal pads are our specialty. Our manufacturing site is in...

EMI/RFI Bulb/Hollow Gaskets – The Softest EMI/RFI Gasket

At NEDC, we mostly die-cut, knife-cut, or waterjet cut gaskets. However,...

Thermal Interface Pads/Liquids for Solid State Drives(SSDs)

As the industry moves from hard-drives(HDDs) to solid-state drives(SSDs). SSDs offer significant advantages over their hard drive counterparts. However, since SSDs operate through an electrical current, they still get hot- just like every electronic. Heat continues to...

TFLEX 600 | High-Compliance Thermal Pads | Low-Stress

NEDC manufactures thermal pads for many different customers. The thing I love about thermal pads, there is so many of them. Each one has different properties, and has its own fit for applications. Properties of TFLEX 600 Thermal Pad TFLEX 600 is a boron nitride...

Silicone Foam Challenges, and Silicone Foam Alternatives

Over the past two years, silicone foam has become a particularly challenged material when it comes to lead times. As of this writing, there has been cases where we have waited a year for some silicone foam. Although, it is true, lead times have improved dramatically...

Engineering Note: Hole Diameters: How low can you go?

At NEDC, cutting gaskets is what we do. Gaskets typically have holes in them to provide room for screws or bolts to go through them in order to provide pressure, and then for that reason, also to provide compression for the gasket to seat/seal properly. How small is...

Liners for Die-Cutting – Why is there Thick, or Thin Liners?

NEDC is an authorized converter for 3M company. For that reason, we often get questions from customers about the adhesive tape products we offer. Customers often ask, what is the difference between this tape, and this tape? The reason customers ask this question, is a...

Application Note for Speaker Gasket Found In Airport

When people ask me what I do for a living, I'll be honest- I struggle trying to tell them what I do. I usually end up just saying, most of the parts we make are for aerospace/military applications. Which is true. However, frankly that is a terrible answer. I'm going...

Tips/Tricks to Avoid Supply Chain Disruptions | Custom Die-Cutters

In this supply chain taxed environment, I thought I’d write a blog about how to keep your supply chain moving at the maximum speed possible- whatever that may be nowadays. In this blog, we will provide some tips, and tricks to keep your supply chain moving....

Why so many Gap Pads/Thermal Pads? Some Thoughts

I often get the question, “Why are there so many thermal pads?” In addition, I always joke there are so many types of thermal pads, that they are sort of like ice cream flavors. There is a type of ice cream for everybody. Some Thoughts I had on "Why so Many Gap...

FDA, 21 CFR 177.2600 Gasketing Materials | Neoprene, Nitrile, FKM, EPDM

About 8 years ago, when I had first started blog writing- oh God, don’t remind me it was 8 years ago, I wrote a blog on FDA Gaskets for silicone rubber products. This blog only covered what was available for silicone rubber products. In that blog, we neglected rubber...

3M Adhesive 350 | Cut Shapes/Custom Gaskets

At NEDC, we are a 3M Converter. For that reason, we are constantly dealing with high performance tapes. We thought we’d do a blog on all of the tapes that have the 350 Adhesive Tapes. Properties of Adhesive 350 Tapes: -High Heat Stress (450°F for short periods, with...

Knife-Cutting | New Capabilities at New England Die Cutting

Before the close of the 2022 year, NEDC bought a knife-cutting machine. This knife-cutter will enable NEDC to provide more quality parts to its customers. This machine has a maximum table length of 60’’ x 120’’. NEDC is very excited to announce this to our customers....

Eccosorb GDS | Broadband Absorber | Custom Die-Cut

NEDC die-cut RF absorbers all the time. In one blog, we discussed Eccosorb MCS in a blog early in 2020. One of the more popular materials that we die-cut for customers that require RF absorbers is Eccosorb GDS. Between Eccosorb GDS, and Eccosorb MCS, they probably...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

Can you use a Thermal Pad/Gap Pad more than Once?

My blogs largely originated from the various questions I have gotten from customers over the years. This includes the most popular ones. One question I realized I get an awful lot is : “Are Gap Pads Reusable?” Heres my short answer, “It depends, but I wouldn’t ever”....

Die-Cutting vs Laser Cutting, Epoxy Preforms: Part 2

I had a customer call the other day, saying he heard that laser cutting was better than die-cutting for frozen epoxy preforms. Heres the thought I had in my head “Why does this keep coming up!?” Heres my thought, and then I’m going dive into every advantage, and...

Super-Soft Silicone Rubber Gaskets | Tight-Tolerance/High-Temperature

At NEDC, Custom Silicone Rubber Gaskets are a common product we sell. Included in that category are the Super-Soft Silicone Rubber Gaskets that are available. When I think soft gaskets, typically below 40A durometer would be considered soft. However, when I think of...