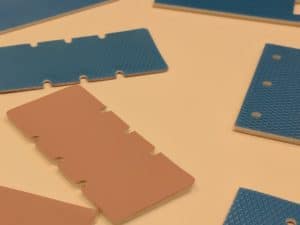

thermal pads die-cut

I often get the question, “Why are there so many thermal pads?” In addition, I always joke there are so many types of thermal pads, that they are sort of like ice cream flavors. There is a type of ice cream for everybody.

Some Thoughts I had on “Why so Many Gap Pads?”

I thought I’d compile a few reasons that there are so many thermal pads. By doing this, I essentially listed all of the properties/characteristics that a thermal pad could have :

-Thermal Conductivity

Thermal Conductivity is in high demand for Gap Pads. 12 W/m-K commercially was rare to non-existent. Today, its a norm, and expected. However, thermal conductivity is not EVERYTHING!

-Thicknesses Available

Thicknesses available you wouldn’t think is a big thing- however, few Gap Pads come in thicknesses of .250’’, and few Sil-Pads, or thinner pads come in .005’’, like Sil-Pad 800

-Cost structure

For example, I had a customer the other day, I gave them a price for a pretty big thermal pad. Frankly, I thought it was a good price. This person came back, and asked me to cut it in half. This comes back to the Gap Pads that are high performance versus Gap Pad that are more economical but compromise on rigidly high performing.

-Reinforcement (fiberglass/no fiberglass)

Each thermal pad has a different level of reinforcement.

-Outgassing Properties

Outgassing is a major concern among aerospace/space players. For example, Gap Pad HC5.0 has ultra low outgassing metrics.

-Thermal Impedance

As I mentioned above, thermal conductivity is not everything. Thermal Impedence is a much better indicator to how the thermal material may perform.

-Modulus

The ULM series comes to mind, along with the S-Class materials come to mind. These materials have lower modulus to offer a better thermal performance profile. Most of the time these Gap Pads are in the form of Young’s Modulus

-Electrical Isolation

Some Thermal Pads offer electrical isolation- while some do not. Often, and I mean- very often, electrical isolation is an expectation of thermal pads.

Between all of these properties, each one imparts a special characteristic that ranges from critical to not-important. They all come together to make a perfect fit sometimes in an application. For that reason, some of the thermal gap fillers that are available now were once formulated due to a customer application that required it.

More Information on Thermal Pads

NEDC die-cuts, knife-cuts, and waterjet-cut thermal pads. For more information on thermal pads, please contact sales@nedc.com.