Electrical Insulators

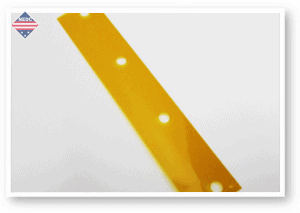

Kapton Insulator

Die-Cut Insulators were one of NEDC first products. This product line went along with gaskets as some of the first parts NEDC cut for customers. When NEDC first started, most electrical insulators were die-cut. However, with the new machinery that NEDC employees, waterjet, laser, and other machines also play a part.

Materials

Many of the materials used for electrical insulation are also used on our other products. In other words, gaskets, and thermal pads may also isolate an electrical current. As a result, materials including plastic, thermal interface pads, rubber, and paper like products all may have the ability to be electrically isolating.

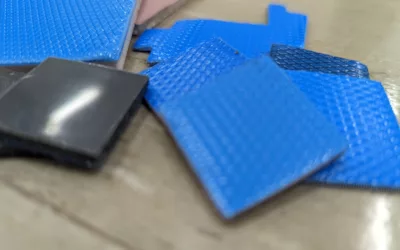

Thermal Pads

One of NEDCs core products are thermal pads. For that reason, its interesting that thermal pads oftentimes serve as electrical insulators. Products such as Sil Pad®, and Gap Pad®, are marketed because of their high volume resistivity making them ideal for electrical insulation while providing a thermal management solution.

Many Gap Pad® products offer electrically insulating properties. Gap Pad® products such as GPVOUS, GPVOS, GP5000S35, GPHC3.0, GPHC5.0 offer high levels of electrical insulating properties. This is in addition to their thermally conductive properties as well.

Many Sil-Pad® products offer electrically insulating properties. Sil Pad® products that are electrically isolating include Sil-Pad 900S, Sil-Pad 2000, Sil-Pad 400, and others.

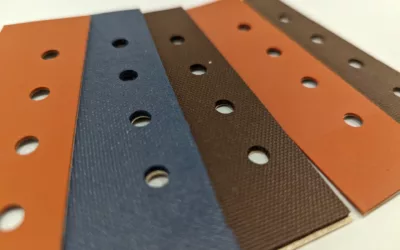

Thin Plastics

Many thin plastics that NEDC cuts are electrical insulators. Materials like Kapton®, Mylar®, Lexan®, Formex®, G10/FR4 Epoxyglass all may serve as electrical insulators. These plastics can be converted into die-cut insulators.

Mylar® is a polyethylene terephthalate(PET) that is registered by DuPont. These materials usually come in thin films ranging from .002” to .014” in thickness. It is commonly used as an electrical insulator. MYLAR® A is the most common type. Mylar® MO is approved for Class B insulation.

Kapton® is a polyimide film that is registered by DuPont. This plastic can be certified to MIL-P-46112 Type 1, and ASTM D5213 Type 1 Item A. It usually comes in thin formats such as .0005” to .005” in thickness. Anything above this enters into the category of Cirlex®. Common applications include insulation blankets, and insulation tubing. There are a few different types of Kapton Film besides Kapton HN. These include Kapton® FN, Kapton® FWR, Kapton® GS, Kapton® MT+, and Kapton® RS.

Lexan® is a polycarbonate plastic that is oftentimes die-cut in film form. Lexan® plastic is a registered trademark by SABIC. Lexan® is extremely tough, but is formable. There are many different types. However, NEDC mainly die-cuts 8010, FR700, and others.

Formex® is a flame retardant polyproylene plastic. Formex® has excellent electrical properties. This plastic is fungus inert. There is GK-5, GK-10, GK-17, GK-30, GK-40, and GK-62. These plastics run from .005” in thickness to .062”.

Epoxyglass/G10/FR4 is a plastic like material that is really laminated glass with epoxy bonding it together. These materials are oftentimes used as electrical insulators. Most often NEDC die-cuts these materials, the thickness is below .015”. G10 is generally not thought of flame retardant. However, FR4 is flame retardant. MIL-I-24768 encompasses many different options. G10 being /2, and FR4 being /27. These materials are generally available .005”-many inches thick.

Rubber

At NEDC we cut many rubber materials to make gaskets. However, rubber materials can also sometimes serve as electrical insulators. For example, silicone rubber is a great electrical insulator that is commonly used in cables or wiring. Some other rubber materials used for electrical insulation include fluorosilicone, neoprene, EPDM, or urethane.

Silicone Rubber is commonly used as an electrical insulator. In fact, this material is probably the most commonly used material at NEDC. We use silicone rubber for gaskets, insulators, vibration dampening, and many other uses. Common certifications include A-A-59588, ZZR765, and others.

Fluorosilicone Rubber is another commonly used electrical insulator. However, it is not as commonly used as silicone because of its other qualities that tend to make it more expensive. Some specifications include MIL-R-25988, AMS-3329, and others.

Neoprene Rubber is a synthetic rubber also another commonly used electrical insulator. It is used in cable jacketing for wire and cable. It is often flame resistant.

Paper like Products – Die Cut Insulators

Many paper like products serve as electrical insulators. Some common ones that NEDC sees are Nomex®, Fishpaper, Kraft Pulp, and others.

Nomex® is a aramid fiber paper. It has a high dielectric strength. This paper is used for The most common type of Nomex® is Nomex 410. Nomex 410 comes in a number of thicknesses ranging from .002” to .030”.

Fishpaper is an electrically insulating paper that is resistant to heat. It is an excellent insulator used in fuse tubes, and electronic devices. Thicknesses of fishpaper range from thin (.005”) to thicker (.030”). Specifications include MIL-I-495. It mostly comes in dark colors such as gray, or dark blue.

Electrical Qualities to look for with Die-Cut Insulators

Volume Resistivity

Volume Resistvity plays a huge part in die-cut insulators. The higher this number the better. A low number indicates the materials conductivity. This number indicates how much the insulator resists electric currents.

Dielectric Strength

Dielectric Strength is an important metric with die-cut insulators. It helps determine the quality of the insulator. It is defined as the maximum voltage required to produce dielectric breakdown through the material. All the materials above would register a high dielectric strength, for example.

Thermal Pad, Silicone, g10, Sponge

Conclusion

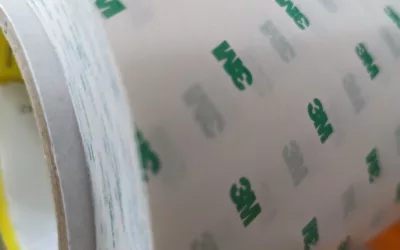

As with most materials NEDC provides, adhesive backing is available on certain products. Some common tapes we use from 3M are acrylic based 9485PC, 9472, 467MP, and 9469PC. For more information on electrical insulators, or you believe you have a project that could use a die-cut insulator, please contact sales@nedc.com.

Electrical Insulators Blog

NEDC Introduces First Thermal Pad Experiment Video

This video shows how a thermal pad actually works with the analogy of cooking.

Previous Posts

Applications: Scanner, PDDs, Analyzers – Gaskets, Pads, Thermal Pads

At NEDC, we manufacture an incredible array of applications. In today's...

Silicone Rubber Gasketing, Peroxide vs. Platinum Cured

Customers buy all sorts of silicone rubber gaskets. In fact, silicone...

Can you use a Thermal Pad/Gap Pad more than Once?

My blogs largely originated from the various questions I have gotten from...

Supported Thermal Pads | Why are they Supported?

I have made it obvious that we manufacture thermal pads at NEDC. I practically mention it in every single blog. Why are Thermal Pads Supported? Thermal Pads are supported because they are essentially made of putty. It's important to distinguish there are about four...

Developments/Challenges at NEDC in 2022

At NEDC, we closed a strong 2022. However, it was not all sunshine, and rainbows. It was quite the opposite. We faced a number of challenges. There weren't only bad things, there was a few silver linings as well. Challenges/New Developments at NEDC in 2022 ...

PTFE Coated Fiberglass Fabric | Custom Die-Cut Parts

At NEDC, we die cut all sorts of products. One product that I’m surprised I have not mentioned in the 5 years I’ve been doing the blog, is PTFE Coated Fiberglass Fabric materials. Right before the turn of the New Year, I decided it may be a good idea to discuss...

Open Cell Foam/Sponge | What is it, What is it good for?

At NEDC, we cut all kinds of cellular sponge products. One thing we have never really discussed on this blog, is “What is Open Cell Foam?” We discussed the differences between Open Cell Sponge, and Closed Cell Sponge, but I thought to myself, maybe a more...

Natural Gum Rubber | Custom Die Cut/Waterjet Cut Parts

It surprises me slightly, just slightly that we have posted over 220 blogs, but we have never discussed natural rubber. Natural rubber is called that because it was the first type of rubber discovered when the fateful Charles Goodyear accidentally dropped his natural...

Tips for your Gasket to Consider | Custom Gasket Suggestions

In a blog I wrote in the past, I had discussed how to make your gasket more cost effective. At times, I feel like I have talked about everything about gasket design- one blog I have not talked about is a few tips on designing gaskets. Tips: 1. Temperature Range When...

High Temperature Transfer Tapes | Die-Cut Tape/Laminated

NEDC die-cuts high-temperature gasketing materials all the time. Many times, customers would like a gasketing material to have a tape on them. Most applications don’t require a high temperature adhesive because its just to help during assembly- however, there are...

Cooking an Egg Through a Thermal Pad | How they Work

At NEDC, we cut thermal pads like it's our job- cause guess what.. It is. Oftentimes, when we are talking to customers- they may not know exactly how thermal pads work because it may not be obvious what a good insulator air is in an application. A few weeks ago, right...

VHB GPH Tape | Powder Coated/Liquid Painting | Die-Cut Tape

NEDC is a major supplier of 3M VHB Tape. There are VHB Tapes for all sorts of applications. However, it is well known in the industry that sticking things to powder coat, and liquid painted surfaces can be very tricky. Considering this, 3M Company has come up with a...

Silicone Sponge vs. Silicone Foam | Whats the Differences? Are they different?

We see on prints all the time “R10480S Silicone Foam” or “HT-800 Silicone Sponge”. Its clear what the customer is requiring. However- these requirements are slightly incorrect. It should read “R10480S Silicone Sponge” and “HT-800 Silicone Foam”. WIth that said, when I...

Speaker Gaskets | Custom Die-Cut Shapes | Foam/Sponge/Cork

Speakers are everywhere these days. I have some in my car, I have two on my desk (currently playing Vivaldi). In our last blog, we talked about rattling/pinging that can be present in different environments. As discussed in that blog, we suggest foam/sponge to absorb...

Foams/Sponges to Stop Rattling/Pinging/Buzzing in Applications

A few years ago, I had a car that had a sunglasses holder near the sunroof. I’m not going to name the manufacturer because I’m never buying a car from them again- however- One day(don’t ask me why, it started rattling).. It made this all the time. Finally, after a...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

Double Coated Tape 3M 9731- Acrylic/Silicone

We are an authorized 3M Converter at NEDC. As a result, we work with many of their tape products. These include VHB Tapes, EMI Shielding Tapes, Transfer Tapes, and many others. One of the tapes we work with often is 3M 9731 Double Coated Tape. This tape has the great...

Sil-Pad 900S Thermal Pad | Thin Thermal Pad | Custom Die Cut Shapes

NEDC has been die-cutting thermal pads since its inception in 1982. One of the more popular products Sil-Pad 900S by Henkel’s Bergquist. It is one of the most commonly die-cut materials NEDC converts. This product is part of the Sil-Pad family, featuring great thermal...

Silicone Gaskets, Pads- Silicone Foam, Sponge, Solid, EMI/RFI Shielding

At NEDC, we offer an incredibly wide range of materials. High performing materials such as silicone rubber is one of them. The reason for this is because silicone has countless incredible properties. These include great electrical properties, high & low...