Laser Cutting Services

Epoxy Preforms, Tapes, and Shim Stock

Laser Cutting Machine

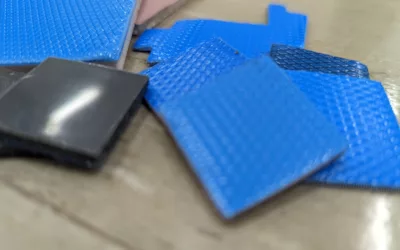

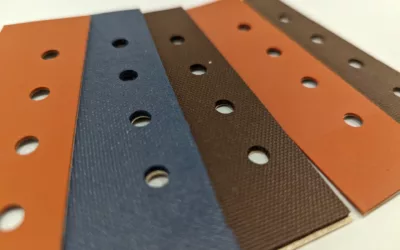

LCD Gaskets, Touchscreen gaskets

LCD Gaskets, Touchscreen gaskets

-No tooling cost

With conventional die cutting, unique shapes can be expensive in tooling cost. With laser cutting no tooling cost is required, because there is no tool, except the laser itself!

-Simple DXF allows for easy cutting

Laser Cutting requires only an electronic file such as a DXF to function. These files give the machine instructions of how to cut, when to cut, and where to cut.

-Highly precise tolerancing

With conventional die cutting, meeting certain tolerance expectations on highly complex parts can be a challenge. However, tolerancing has never been tighter on laser cutting machines. Our machines can provide some dimensions as tight as +/- .002” depending on the material.

-High material utilization

Part of offering laser cutting services is also to attempt to give the customer the best price possible. We can nest parts in different directions, and orientations to make the best possible use of the material we have. Some materials can be expensive, so material utilization becomes very important.

-Lots of room for adjustments because of no tooling

One of the downsides of using conventional die cutting is that once the tool is made it can be difficult to adjust. For example, if a diameter is the wrong size, we may be able to fix it but sometimes we cannot. With laser cutting you can easily adjust things to make them smaller, bigger, longer, or wider. Nothing is set in stone with laser cutting software. This can be a huge benefit when cutting prototypes.

-Low quantity runs

We would not say laser cutting machines do not move fast. However, laser cutting oftentimes hits it stride at lower quantity runs. With lower quantities, the mix of no tooling cost, room for adjustment, and high material utilization produces a large value proposition.

Products & Materials:

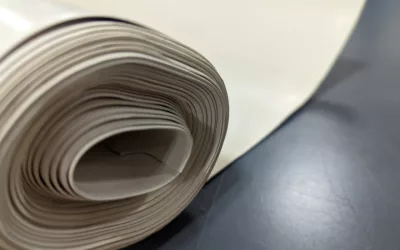

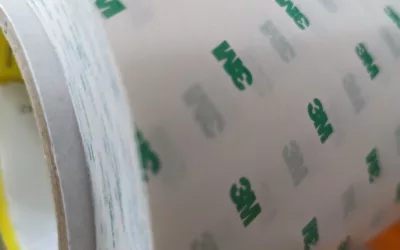

High-Performance Tapes

At NEDC, we are an authorized converter for the 3M Company. We have access to procure many tapes such as VHB Tapes, Transfer Tapes, Double Sided Tapes, and other unique tape configurations. We utilize our laser cutting services to cut these tapes for our customers. Oftentimes, we use our laser cutting machines to be able to kiss-cut parts. We cut parts to liners to make them easy for our customers to remove off during assembly.

Some common 3M tapes we cut on our laser include:

-VHB 3M 5952, 4941, 5909, 5907 and others

-Transfer Tapes 3M 9472, 467MP, 9469PC, 9485PC, 9471LE, 9472LE and others

-Double Sided Tapes 3M 7945MP, 415, and others

laser-cut ablefilm preforms

laser-cut ablefilm preforms

Epoxy Film Adhesives

One of the materials that utilizes our laser cutting services fairly often is Ablefilm®. Ablefilm® and other frozen epoxy film adhesives can be laser cut with these machines. Laser Cutting is one of the only to cut these film adhesives. To produce the small diameters, and interesting, dynamic curves that some circuit boards provide, laser cutting may be necessary. These adhesive films are normally on the thinner side- going as low as .002”. Laser Cutting enables a wide amount of latitude on what is possible to be cut. These can include:

-Tight Tolerancing

-Small Diameters

-Small Preforms

-Many Diameters

-Unique Cutouts

These Ablefilm® products may include 5025E, ECF561E, CF3350, 5020K, and 550K.

Kraft Papers

Paper products traditionally do very well during the laser cutting process. Kraft Paper is also a great candidate for our laser cutting machine. We can cut Kraft Paper, Fishpaper, and Vulcanized Fiber. These materials come in different densities, weights, and specifications.

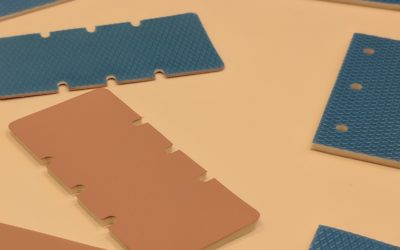

Plastic Shim Stock

We use laser cutting services to cut many thin plastic like materials. One of the more popular materials is thin polyester(PET, or PETG). These materials are usually color coded to designate thickness. In addition, some other materials besides polyester can be used as shim stock. Not all plastics can be cut on our laser cutting machine but many can be.

NEDC owns and operates several laser cutting machines. As part of our laser cutting services, NEDC is use to demanding requirements placed on parts. As a result, these lasers operate with very precise accuracy, carrying the ability to hold some parts within a +/- .002” tolerance. It is good to keep in mind that laser machines are limited to a certain thickness of all materials. The ability to cut thick materials on a CO2 laser is also a function of the amount of the power the laser is able to produce.

However, it is good to keep in mind that while laser cutting can be a solution of a lot of challenges, there are some materials our laser has trouble with. These materials include metals, thicker plastics, and other materials. For more information on laser cutting or you believe you have a part could be potentially laser cut, please contact sales@nedc.com.

Laser Cutting Blog

Frozen Epoxy Films in Stock at NEDC!

NEDC is a converter of frozen epoxy films to make custom preforms for customers to buy. For that reason, NEDC has many frozen films in stock. These include: Ablefilm 5025E Ablefilm 561K Ablefilm CF3350 Ablefilm 566K And others. We wanted to just get it out there on...

Previous Posts

Garlock BLUE-GARD Gasketing Options | Waterjet/Die-Cutting

At NEDC, engineered options are our thing. In this blog, we wanted to...

R10400M (Medium) Flame Retardant Silicone Sponge | Custom Die-Cut Parts

Silicone Sponge, and Silicone Foam are different. I’ve talked about that...

Thermal Pad vs. Thermal Grease/Mica

One common question I hear engineers ask about is if it's better to have...

Why so many Gap Pads/Thermal Pads? Some Thoughts

I often get the question, “Why are there so many thermal pads?” In addition, I always joke there are so many types of thermal pads, that they are sort of like ice cream flavors. There is a type of ice cream for everybody. Some Thoughts I had on "Why so Many Gap...

FDA, 21 CFR 177.2600 Gasketing Materials | Neoprene, Nitrile, FKM, EPDM

About 8 years ago, when I had first started blog writing- oh God, don’t remind me it was 8 years ago, I wrote a blog on FDA Gaskets for silicone rubber products. This blog only covered what was available for silicone rubber products. In that blog, we neglected rubber...

3M Adhesive 350 | Cut Shapes/Custom Gaskets

At NEDC, we are a 3M Converter. For that reason, we are constantly dealing with high performance tapes. We thought we’d do a blog on all of the tapes that have the 350 Adhesive Tapes. Properties of Adhesive 350 Tapes: -High Heat Stress (450°F for short periods, with...

Supported Thermal Pads | Why are they Supported?

I have made it obvious that we manufacture thermal pads at NEDC. I practically mention it in every single blog. Why are Thermal Pads Supported? Thermal Pads are supported because they are essentially made of putty. It's important to distinguish there are about four...

Developments/Challenges at NEDC in 2022

At NEDC, we closed a strong 2022. However, it was not all sunshine, and rainbows. It was quite the opposite. We faced a number of challenges. There weren't only bad things, there was a few silver linings as well. Challenges/New Developments at NEDC in 2022 ...

PTFE Coated Fiberglass Fabric | Custom Die-Cut Parts

At NEDC, we die cut all sorts of products. One product that I’m surprised I have not mentioned in the 5 years I’ve been doing the blog, is PTFE Coated Fiberglass Fabric materials. Right before the turn of the New Year, I decided it may be a good idea to discuss...

Open Cell Foam/Sponge | What is it, What is it good for?

At NEDC, we cut all kinds of cellular sponge products. One thing we have never really discussed on this blog, is “What is Open Cell Foam?” We discussed the differences between Open Cell Sponge, and Closed Cell Sponge, but I thought to myself, maybe a more...

Natural Gum Rubber | Custom Die Cut/Waterjet Cut Parts

It surprises me slightly, just slightly that we have posted over 220 blogs, but we have never discussed natural rubber. Natural rubber is called that because it was the first type of rubber discovered when the fateful Charles Goodyear accidentally dropped his natural...

Tips for your Gasket to Consider | Custom Gasket Suggestions

In a blog I wrote in the past, I had discussed how to make your gasket more cost effective. At times, I feel like I have talked about everything about gasket design- one blog I have not talked about is a few tips on designing gaskets. Tips: 1. Temperature Range When...

High Temperature Transfer Tapes | Die-Cut Tape/Laminated

NEDC die-cuts high-temperature gasketing materials all the time. Many times, customers would like a gasketing material to have a tape on them. Most applications don’t require a high temperature adhesive because its just to help during assembly- however, there are...

Cooking an Egg Through a Thermal Pad | How they Work

At NEDC, we cut thermal pads like it's our job- cause guess what.. It is. Oftentimes, when we are talking to customers- they may not know exactly how thermal pads work because it may not be obvious what a good insulator air is in an application. A few weeks ago, right...

Speaker Gaskets | Custom Die-Cut Shapes | Foam/Sponge/Cork

Speakers are everywhere these days. I have some in my car, I have two on my desk (currently playing Vivaldi). In our last blog, we talked about rattling/pinging that can be present in different environments. As discussed in that blog, we suggest foam/sponge to absorb...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

Can you use a Thermal Pad/Gap Pad more than Once?

My blogs largely originated from the various questions I have gotten from customers over the years. This includes the most popular ones. One question I realized I get an awful lot is : “Are Gap Pads Reusable?” Heres my short answer, “It depends, but I wouldn’t ever”....

Die-Cutting vs Laser Cutting, Epoxy Preforms: Part 2

I had a customer call the other day, saying he heard that laser cutting was better than die-cutting for frozen epoxy preforms. Heres the thought I had in my head “Why does this keep coming up!?” Heres my thought, and then I’m going dive into every advantage, and...

Super-Soft Silicone Rubber Gaskets | Tight-Tolerance/High-Temperature

At NEDC, Custom Silicone Rubber Gaskets are a common product we sell. Included in that category are the Super-Soft Silicone Rubber Gaskets that are available. When I think soft gaskets, typically below 40A durometer would be considered soft. However, when I think of...