Laser Cutting Services

Epoxy Preforms, Tapes, and Shim Stock

Laser Cutting Machine

LCD Gaskets, Touchscreen gaskets

LCD Gaskets, Touchscreen gaskets

-No tooling cost

With conventional die cutting, unique shapes can be expensive in tooling cost. With laser cutting no tooling cost is required, because there is no tool, except the laser itself!

-Simple DXF allows for easy cutting

Laser Cutting requires only an electronic file such as a DXF to function. These files give the machine instructions of how to cut, when to cut, and where to cut.

-Highly precise tolerancing

With conventional die cutting, meeting certain tolerance expectations on highly complex parts can be a challenge. However, tolerancing has never been tighter on laser cutting machines. Our machines can provide some dimensions as tight as +/- .002” depending on the material.

-High material utilization

Part of offering laser cutting services is also to attempt to give the customer the best price possible. We can nest parts in different directions, and orientations to make the best possible use of the material we have. Some materials can be expensive, so material utilization becomes very important.

-Lots of room for adjustments because of no tooling

One of the downsides of using conventional die cutting is that once the tool is made it can be difficult to adjust. For example, if a diameter is the wrong size, we may be able to fix it but sometimes we cannot. With laser cutting you can easily adjust things to make them smaller, bigger, longer, or wider. Nothing is set in stone with laser cutting software. This can be a huge benefit when cutting prototypes.

-Low quantity runs

We would not say laser cutting machines do not move fast. However, laser cutting oftentimes hits it stride at lower quantity runs. With lower quantities, the mix of no tooling cost, room for adjustment, and high material utilization produces a large value proposition.

Products & Materials:

High-Performance Tapes

At NEDC, we are an authorized converter for the 3M Company. We have access to procure many tapes such as VHB Tapes, Transfer Tapes, Double Sided Tapes, and other unique tape configurations. We utilize our laser cutting services to cut these tapes for our customers. Oftentimes, we use our laser cutting machines to be able to kiss-cut parts. We cut parts to liners to make them easy for our customers to remove off during assembly.

Some common 3M tapes we cut on our laser include:

-VHB 3M 5952, 4941, 5909, 5907 and others

-Transfer Tapes 3M 9472, 467MP, 9469PC, 9485PC, 9471LE, 9472LE and others

-Double Sided Tapes 3M 7945MP, 415, and others

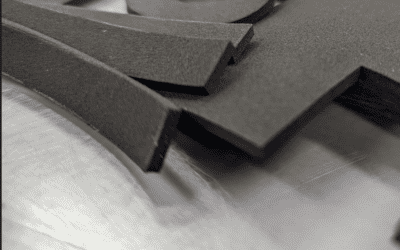

laser-cut ablefilm preforms

laser-cut ablefilm preforms

Epoxy Film Adhesives

One of the materials that utilizes our laser cutting services fairly often is Ablefilm®. Ablefilm® and other frozen epoxy film adhesives can be laser cut with these machines. Laser Cutting is one of the only to cut these film adhesives. To produce the small diameters, and interesting, dynamic curves that some circuit boards provide, laser cutting may be necessary. These adhesive films are normally on the thinner side- going as low as .002”. Laser Cutting enables a wide amount of latitude on what is possible to be cut. These can include:

-Tight Tolerancing

-Small Diameters

-Small Preforms

-Many Diameters

-Unique Cutouts

These Ablefilm® products may include 5025E, ECF561E, CF3350, 5020K, and 550K.

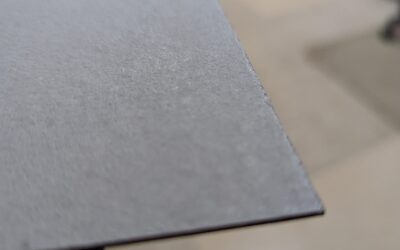

Kraft Papers

Paper products traditionally do very well during the laser cutting process. Kraft Paper is also a great candidate for our laser cutting machine. We can cut Kraft Paper, Fishpaper, and Vulcanized Fiber. These materials come in different densities, weights, and specifications.

Plastic Shim Stock

We use laser cutting services to cut many thin plastic like materials. One of the more popular materials is thin polyester(PET, or PETG). These materials are usually color coded to designate thickness. In addition, some other materials besides polyester can be used as shim stock. Not all plastics can be cut on our laser cutting machine but many can be.

NEDC owns and operates several laser cutting machines. As part of our laser cutting services, NEDC is use to demanding requirements placed on parts. As a result, these lasers operate with very precise accuracy, carrying the ability to hold some parts within a +/- .002” tolerance. It is good to keep in mind that laser machines are limited to a certain thickness of all materials. The ability to cut thick materials on a CO2 laser is also a function of the amount of the power the laser is able to produce.

However, it is good to keep in mind that while laser cutting can be a solution of a lot of challenges, there are some materials our laser has trouble with. These materials include metals, thicker plastics, and other materials. For more information on laser cutting or you believe you have a part could be potentially laser cut, please contact sales@nedc.com.

Laser Cutting Blog

Thin Gasketing Options | .015”, & Below | High Performance Gaskets

Applications get smaller, and smaller everyday. As footprints of the electronics we serve get thinner, and lighter i.e electronic signs, tablets, and other peripherals, the gasketing must get thinner to accommodate it. We have customers come in all the time looking...

Previous Posts

Die-Cutting vs Laser Cutting, Epoxy Preforms: Part 2

I had a customer call the other day, saying he heard that laser cutting...

IP Ratings – Gaskets & Ratings | Particles/Liquid Ingress

IP (Ingress Protection or International Protection) ratings are a common...

Thermal Interface Pads/Liquids for Solid State Drives(SSDs)

As the industry moves from hard-drives(HDDs) to solid-state drives(SSDs)....

Foams/Sponges to Stop Rattling/Pinging/Buzzing in Applications

A few years ago, I had a car that had a sunglasses holder near the sunroof. I’m not going to name the manufacturer because I’m never buying a car from them again- however- One day(don’t ask me why, it started rattling).. It made this all the time. Finally, after a...

Sil-Pad A2000 aka SIL PAD TSP A3000 | Custom Die-Cut Thermal Pads

At NEDC, we die-cut a lot of thermal interface materials (TIMs). Cost is always a concern when customers are selecting thermal pads. When selecting an .015’’-.020’’ thin thermal pad, Sil-Pad A2000 is a good choice. Why Select Thermal Interface Pad Sil-Pad A2000? I’m...

Thermal Pad Sample Kit 2.0 | Sil-Pad & Gap Pad in One Kit

During COVID, NEDC released a Thermal Pad Sample Kit. It had a number of Gap Pads on it. We decided to re-release it- new. and improved. Why Thermal Pad Sample Kit 2.0? This time it has a combination of Sil-Pad and Gap Pad on the Thermal Pad Sample Kit. It has...

Weatherproof/Weather Resistant Gaskets | Outdoor Gaskets

At NEDC, we discuss types of gaskets with customers all of the time. It can range from high temperature gaskets, to fuel resistant gaskets. In this blog, we wanted to discuss weather resistant gasketing materials. Another thing I’ve heard customers called weatherproof...

3M Thermal Interface Pads | Silicone – Acrylic | Die-Cut Thermal Pads

At NEDC, we cut thermal pads on a frequent basis. Customers come all the time, asking for a thermal interface pad for their special electronic, phone this, defense system that. With all of these commercial electronics, and military applications, you need a reliable,...

PORON® Condux Plus™ | Custom Waterjet Cutting/Die Cutting Shapes

At NEDC, we cut a lot of conductive foam for customers. One of the conductive foams that we have a lot of success with is PORON® Condux Plus™. There are many reasons for this, but the below are a highlighted few I thought I’d share. Uses for PORON® Condux Plus™...

Membrane Switch Spacers | Custom Die Cut/Laser-Cut Shapes

If you open up a membrane switch, you will find there are 3M products all over the place. 3M 467MP, 3M 467MP liner- any die-cutter who is worth their weight knows 3M 467MP is a commercial staple for this reason. NEDC provides all sorts of insulators, and spacers for...

Flame Retardant Adhesive Transfer Tape | Lamination, Die-Cutting

At NEDC, we stock a lot of materials that are flame retardant. In fact, we have a page that just mentions all the flame retardant materials we have. These include gasketing, thermal pads, absorbers, and other types of materials. One thing we have not mentioned on this...

Battery Cushion Pads | Soft Custom Pads | Foam, Sponge | Custom-Cut

At NEDC, we manufacture a lot of products. Battery Cushion Pads are a common product we make. Customers who are making a modular electronic, oftentimes have a battery that also requires cushioning, or thermal cooling. What are Battery Cushion Pads Used for? Battery...

Fishpaper/Vulcanized Fibre | Custom Die Cutting/Laser Cutting

At NEDC, insulators are one of our core products. Many different electrical insulation materials are among products we cut into custom shapes. However, fishpaper, and vulcanized fiber paper products are among the most popular electrical insulation materials we use. ...

Q-Pad 3 aka SIL PAD TSP Q2000 | Thermal Grease Replacement

At NEDC, thermal pads are our specialty. However, oftentimes customers are looking for a thermal pad that is a grease replacement, that isn’t damaged by reflow solder baths. To be honest, Q-Pad 3 is a unique product for this reason. Q-Pad 3 is a fiberglass reinforced...

ESD Gaskets | Neoprene/Silicone Gaskets, Pads | Custom Die-Cut

At NEDC, we manufacture gaskets, and custom pads. One of the more interesting materials offer is electrostatic dissipative(ESD) gasketing. Out of those materials we manufacture ESD Gaskets. What is ElectroStatic Dissipative Gasketing? It might be a good idea to start...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

Double Coated Tape 3M 9731- Acrylic/Silicone

We are an authorized 3M Converter at NEDC. As a result, we work with many of their tape products. These include VHB Tapes, EMI Shielding Tapes, Transfer Tapes, and many others. One of the tapes we work with often is 3M 9731 Double Coated Tape. This tape has the great...

Sil-Pad 900S Thermal Pad | Thin Thermal Pad | Custom Die Cut Shapes

NEDC has been die-cutting thermal pads since its inception in 1982. One of the more popular products Sil-Pad 900S by Henkel’s Bergquist. It is one of the most commonly die-cut materials NEDC converts. This product is part of the Sil-Pad family, featuring great thermal...

Silicone Gaskets, Pads- Silicone Foam, Sponge, Solid, EMI/RFI Shielding

At NEDC, we offer an incredibly wide range of materials. High performing materials such as silicone rubber is one of them. The reason for this is because silicone has countless incredible properties. These include great electrical properties, high & low...