Waterjet Cutting

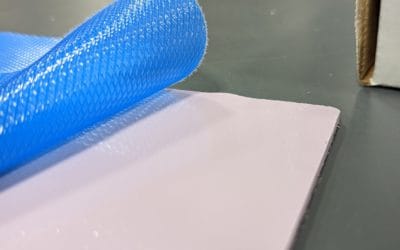

Foam, Solid Gaskets, Thermal Pads, Absorbers, and Electrical Insulators

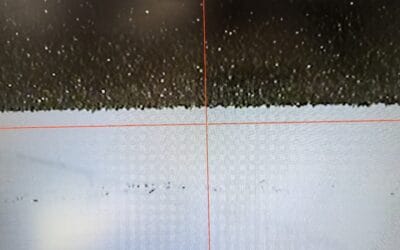

Waterjet Cutting PSA-backed Neoprene Gasket

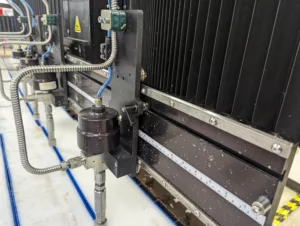

NEDC operates only with state-of-the-art equipment that can handle a wide variety of materials. One of the most sophisticated machines NEDC owns is our Waterjet Cutters. Waterjet Cutting happens through a very unique process. The process starts with a high-powered pump that creates a lot of pressure for the water. The water then exits the head of the waterjet through a premounted sapphire/diamond orifice. All of this action produces an extremely powerful waterjet stream that is forced from the head at incredible speeds, (30,000-50,000psi). This streams pierces the gasketing material creating a clean cut with the most available commodity on the planet, water. The waterjet cutting process allows parts to be nested in a very economical fashion. NEDC is a leading waterjet cutting supplier for gaskets, insulators, and other elastomeric products such as thermal filler pads, or absorbers.

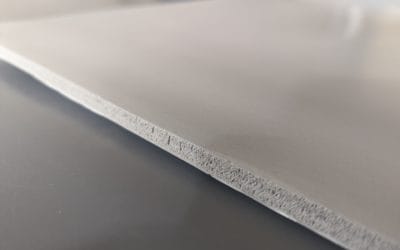

Foam/Sponge Gaskets:

Foam or Sponge gaskets are also cut with our waterjet machine. These materials can be flexible and cause issues in conventional die-cutting. This is due to the elastic nature of these materials; causing the material to snap-back into an hourglass like shape. However, with a waterjet focusing on one hole/feature/cut at a time, meeting tolerance requirements becomes easier.

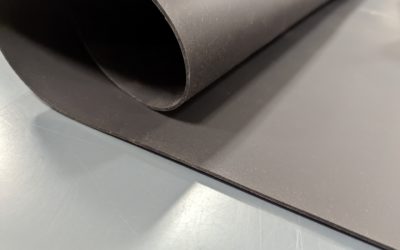

Solid Rubber Gaskets:

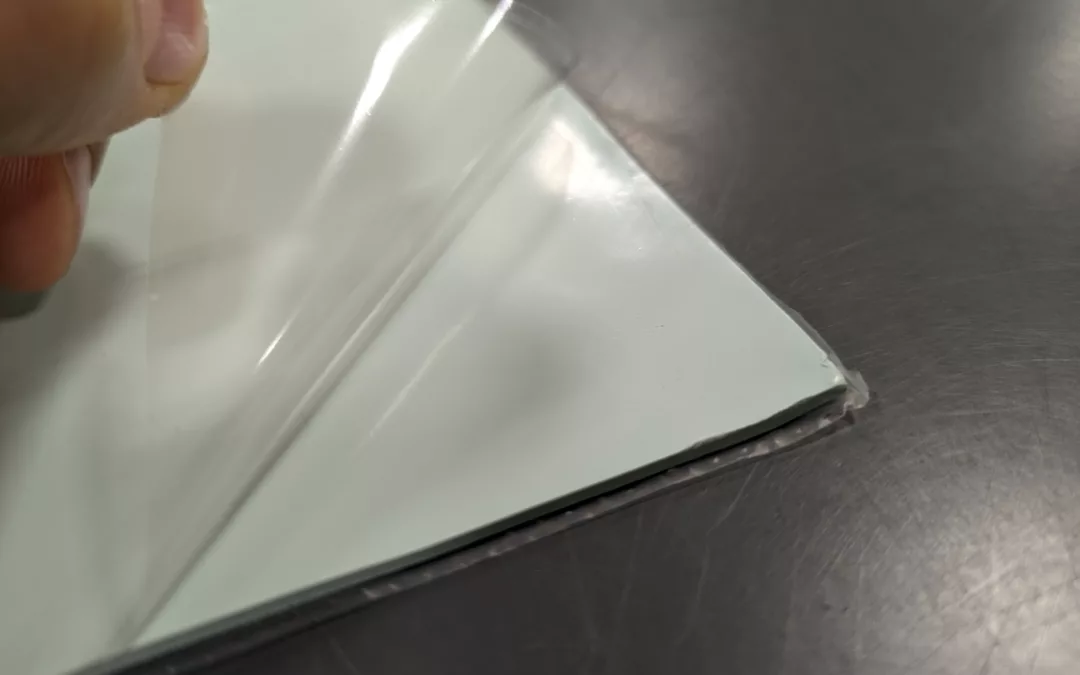

At NEDC, the main function of our waterjet is used to cut solid gaskets. These gaskets can range from nitrile rubber, to neoprene rubber. The reason we do this is because typically when our customer is looking for a few gaskets, we can make them quickly and accurately on our waterjet. It also helps us dial in tight tolerances. Some of these materials include neoprene, fluorosilicone, silicone, nitrile, EPDM, or other conventional rubber materials.

butyl custom gaskets

Advantages of a Waterjet Cutting Machine:

- Extremely Accurate Cuts of Complex Parts

Waterjet cutting offers an incredible amount of accuracy through a coordination of computer software and tight controls. Tolerance can be held as +/- .002” on some materials.

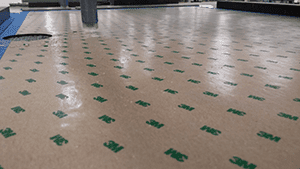

- Maximizes Yield of material through nesting software

Parts can be easily nested to offer our customer the best price possible. In some situations, when a part has a very unique geometry, sometimes the way it may be nested is not quite as linear as a simple horseshoe like part. In these cases, waterjet machines are able to flip, turn, and match the shape in many different directions utilizing every inch of material.

- No tool investment is necessary for water jet cutting

No tool is needed to be made, the DXF is the tool! Please provide an electronic file to aid in programming/cutting. This saves time and money because this file is cut to your specifications.

- Quick Prototypes

At NEDC, we strive to provide prototypes quickly. Waterjet Cutting offers the advantage of the customer being able to engineer the part through their DXF and see what the part will look like in production. The benefit of creating a DXF gives a side benefit of being able to move into production in a much quicker fashion by reducing the time between each prototype rendition. No tool is required to be created, so parts can be cut extremely fast.

- Cut parts from CAD/DXF files, to ensure perfect accuracy of every cut, every time. High degree of repeatability

The DXF is executed by the software in the waterjet cutting machine. When cutting with a DXF file, you can guarantee that no tool will wear/abrade. The waterjet stream itself is always offering a consistent water stream that makes each part nearly identical to the last. This makes reproducibility a huge asset for the machine.

- Allows materials to be cut without the typical compression of conventional die-cutting

Die-Cutting thick foam/sponge materials can result in concavity because of the “burst” action of the die; with a waterjet it is possible to avoid this compression distortion because the waterjet is not compressing the material in the way a conventional die cutting operation would. The difference is, it is slicing through the material in a vertical direction.

- Size of gaskets/parts has little limitations

Cutting gaskets has nearly no limitations when it comes to custom. However, size becomes a concern the bigger the gasket becomes. With waterjet cutting, the only limitation becomes the size of the bed of the waterjet itself. With that said, NEDC has cut 7 foot gaskets before on its waterjet machine.

waterjet cut sponge/foams

Limitations of a Waterjet Cutting Machine:

- Size of parts have limitations

While we just said above that bigger gaskets are easier to cut with a waterjet- as it gets smaller, it may become more difficult. This is because the waterjet stream has a size too, and that starts to limit the features it can cut with accuracy. If the stream and the feature become competitive in size, it can become a challenge.

- Amount of parts being cut

While waterjet cutting is pretty quick, the amount of parts being cut can become a challenge because as mentioned above, cutting with a waterjet only works on one feature at a time. This is in comparison to die-cutting that cuts everything all at once. This is one of the tradeoffs when using a waterjet cutting machine. This drawback generally falls under speed of the overall process.

- Some materials just do not work

Some materials just do not cut well on a waterjet. Fibrous, or otherwise paper like products generally have a tough time cutting because either they soak up the water or they explode when cutting them. Other materials that we know do not work is anything that is impregnanted with wire in a perpendicular direction to the material. It is wise to consult with an experienced waterjet operator before asking a part to be waterjet.

If you have a gasket/part that you believe could be waterjet cut, please send your question or drawing to sales@nedc.com. NEDC has experienced waterjet operators that understand what the machine can do well.

Waterjet Cutting Blog

T-Global Technology | Thermal Gap Pads | Thick, Thin, High W/m-K

At NEDC, thermal pads are our specialty. Our manufacturing site is in Methuen, MA. Across the pond, in the United Kingdom, there is a reputable thermal pad manufacturer. This manufacturer is called T-Global Technology. They make a number of thermal interface...

Previous Posts

Garlock BLUE-GARD Gasketing Options | Waterjet/Die-Cutting

At NEDC, engineered options are our thing. In this blog, we wanted to...

R10400M (Medium) Flame Retardant Silicone Sponge | Custom Die-Cut Parts

Silicone Sponge, and Silicone Foam are different. I’ve talked about that...

Thermal Pad Tackle Box | Sales Tool for Testing/Sampling

At NEDC, we are all about thermal. We enjoy making new sales tools to...

Buna-N/Nitrile Custom Gaskets | Waterjet-Cutting/Die-Cutting

At NEDC, we cut a lot of types of materials. A common type of material chosen for fuel-resistant applications is nitrile gasketing. Nitrile gasketing has an excellent balance of properties that make it a versatile material to pick for applications where fuel resistant...

High Dielectric & Cut-Through Strength Thermal Pads | Polyimide Reinforced Thermal Pad

At NEDC, we cut a number of thermal pads. Through all the thermal pads we sell- we see a large amount of diversity in their make-up. Most thinner thermal pads utilize fiberglass reinforcement. However, there is an alternative such as polyimide that offers great...

Epichlorohydrin Gaskets | Foam/Sponge/Solid Rubber

Fuel Resistance is one of the chief concerns that customers have when they are designing a gasket. As with many gasketing materials there is a solid rubber form as well as a sponge/cellular form of this gasketing material. Epichlorohydrin Rubber is often used in...

VHB Tape 5958FR, Flame Retardant | Die Cutting, Laser Cutting

In the rubber industry flame retardancy is a big topic of discussion and is often required by certain applications. While NEDC does deal with these polymers on a regular basis, we also deal with tapes. Flame retardancy has become such a necessity that the experts in...

UL Ratings Available | Gaskets, Absorbers, Thermal Pads, Insulators

NEDC cuts a lot of materials for different customers. One thing we wanted to assemble was every material we deal with that had a UL Rating, or UL approved materials. We've categorized this into materials generally used for gasketing, absorbers, thermal pads,...

Die-Cut Custom Washers | Rubber, Plastic, Non-Metallic

When you think of Washers you typically think of the thing that you put on before a screw right before you're about to tighten it? We do- but we envision something plastic, or rubber gasketing material. At NEDC we make a different type of washer on a daily basis. What...

CF Conductive Foam | Custom Die-Cut/Waterjet Cut Shapes

Conductive Foam is a unique product group. It has found its niche in the world of EMI Shielding products because of its high compliance, and high electrical conductivity to yield a good EMI shielding gasketing material that can be cut into a number of shapes. What is...

Polyurethane Gaskets | Waterjet-Cut/Die-Cut

A lot of the materials that we cut are built for rugged applications. Polyurethane Gaskets stand out when it comes to a tough gasketing material. However, its good to note - this blog is about polyurethane gasketing materials that are one solid piece- not polyurethane...

Laser-Cutting Epoxy Preforms Vs. Die Cutting | Some Thoughts

At NEDC, we are a build to print vendor. In my few years here,(7 if we're counting- please don’t count though), I have seen customers put some funny things on their prints that imply, or request us to cut a certain way or bag a certain way.. Oftentimes driving up cost...

Flame Retardant Solid Silicone Rubber | Die-Cutting | Waterjet-Cutting

It is often known that a lot of the silicone foams, and silicone sponges that NEDC converts into gaskets are flame retardant. Recently, we did a blog on flame retardant silicone foam/sponge materials. Most gasketing materials are decently fire retardant- however the...

HT-800 Silicone Foam | Die-Cut/Waterjet Cut Gaskets

My favorite silicone foam material is easily HT-800 by Rogers Corp. If someone were to ask why.. (no one is asking) but I’ll explain to all of my 50,000 blog readers why its my favorite silicone foam material. I wrote a blog a few years ago, on silicone foam gaskets,...

GAP PAD TGP HC5000 Color Change | Violet to Natural Gray

6 years ago(I can’t believe that was 6 years ago), I wrote a blog introducing Gap Pad HC5.0, you can find that blog here. Anyways, I remember taking a picture on the day I wrote that blog, and telling everyone I was wearing violet button up shirt(the color of HC5.0)...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.