Waterjet Cutting

Foam, Solid Gaskets, Thermal Pads, Absorbers, and Electrical Insulators

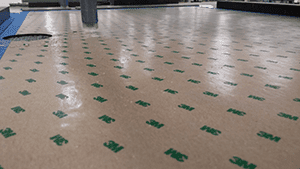

Waterjet Cutting PSA-backed Neoprene Gasket

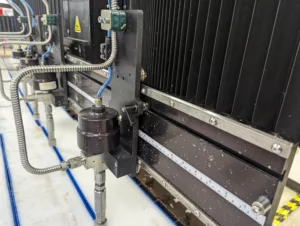

NEDC operates only with state-of-the-art equipment that can handle a wide variety of materials. One of the most sophisticated machines NEDC owns is our Waterjet Cutters. Waterjet Cutting happens through a very unique process. The process starts with a high-powered pump that creates a lot of pressure for the water. The water then exits the head of the waterjet through a premounted sapphire/diamond orifice. All of this action produces an extremely powerful waterjet stream that is forced from the head at incredible speeds, (30,000-50,000psi). This streams pierces the gasketing material creating a clean cut with the most available commodity on the planet, water. The waterjet cutting process allows parts to be nested in a very economical fashion. NEDC is a leading waterjet cutting supplier for gaskets, insulators, and other elastomeric products such as thermal filler pads, or absorbers.

Foam/Sponge Gaskets:

Foam or Sponge gaskets are also cut with our waterjet machine. These materials can be flexible and cause issues in conventional die-cutting. This is due to the elastic nature of these materials; causing the material to snap-back into an hourglass like shape. However, with a waterjet focusing on one hole/feature/cut at a time, meeting tolerance requirements becomes easier.

Solid Rubber Gaskets:

At NEDC, the main function of our waterjet is used to cut solid gaskets. These gaskets can range from nitrile rubber, to neoprene rubber. The reason we do this is because typically when our customer is looking for a few gaskets, we can make them quickly and accurately on our waterjet. It also helps us dial in tight tolerances. Some of these materials include neoprene, fluorosilicone, silicone, nitrile, EPDM, or other conventional rubber materials.

butyl custom gaskets

Advantages of a Waterjet Cutting Machine:

- Extremely Accurate Cuts of Complex Parts

Waterjet cutting offers an incredible amount of accuracy through a coordination of computer software and tight controls. Tolerance can be held as +/- .002” on some materials.

- Maximizes Yield of material through nesting software

Parts can be easily nested to offer our customer the best price possible. In some situations, when a part has a very unique geometry, sometimes the way it may be nested is not quite as linear as a simple horseshoe like part. In these cases, waterjet machines are able to flip, turn, and match the shape in many different directions utilizing every inch of material.

- No tool investment is necessary for water jet cutting

No tool is needed to be made, the DXF is the tool! Please provide an electronic file to aid in programming/cutting. This saves time and money because this file is cut to your specifications.

- Quick Prototypes

At NEDC, we strive to provide prototypes quickly. Waterjet Cutting offers the advantage of the customer being able to engineer the part through their DXF and see what the part will look like in production. The benefit of creating a DXF gives a side benefit of being able to move into production in a much quicker fashion by reducing the time between each prototype rendition. No tool is required to be created, so parts can be cut extremely fast.

- Cut parts from CAD/DXF files, to ensure perfect accuracy of every cut, every time. High degree of repeatability

The DXF is executed by the software in the waterjet cutting machine. When cutting with a DXF file, you can guarantee that no tool will wear/abrade. The waterjet stream itself is always offering a consistent water stream that makes each part nearly identical to the last. This makes reproducibility a huge asset for the machine.

- Allows materials to be cut without the typical compression of conventional die-cutting

Die-Cutting thick foam/sponge materials can result in concavity because of the “burst” action of the die; with a waterjet it is possible to avoid this compression distortion because the waterjet is not compressing the material in the way a conventional die cutting operation would. The difference is, it is slicing through the material in a vertical direction.

- Size of gaskets/parts has little limitations

Cutting gaskets has nearly no limitations when it comes to custom. However, size becomes a concern the bigger the gasket becomes. With waterjet cutting, the only limitation becomes the size of the bed of the waterjet itself. With that said, NEDC has cut 7 foot gaskets before on its waterjet machine.

waterjet cut sponge/foams

Limitations of a Waterjet Cutting Machine:

- Size of parts have limitations

While we just said above that bigger gaskets are easier to cut with a waterjet- as it gets smaller, it may become more difficult. This is because the waterjet stream has a size too, and that starts to limit the features it can cut with accuracy. If the stream and the feature become competitive in size, it can become a challenge.

- Amount of parts being cut

While waterjet cutting is pretty quick, the amount of parts being cut can become a challenge because as mentioned above, cutting with a waterjet only works on one feature at a time. This is in comparison to die-cutting that cuts everything all at once. This is one of the tradeoffs when using a waterjet cutting machine. This drawback generally falls under speed of the overall process.

- Some materials just do not work

Some materials just do not cut well on a waterjet. Fibrous, or otherwise paper like products generally have a tough time cutting because either they soak up the water or they explode when cutting them. Other materials that we know do not work is anything that is impregnanted with wire in a perpendicular direction to the material. It is wise to consult with an experienced waterjet operator before asking a part to be waterjet.

If you have a gasket/part that you believe could be waterjet cut, please send your question or drawing to sales@nedc.com. NEDC has experienced waterjet operators that understand what the machine can do well.

Waterjet Cutting Blog

Thin Gasketing Options | .015”, & Below | High Performance Gaskets

Applications get smaller, and smaller everyday. As footprints of the electronics we serve get thinner, and lighter i.e electronic signs, tablets, and other peripherals, the gasketing must get thinner to accommodate it. We have customers come in all the time looking...

Previous Posts

Long Shelf Life Electrically Conductive Single/Double | EMI Shielding Tapes

We are a 3M converter, and if I’m being honest, I don’t throw a party...

Pure EMI Silver Gaskets, Are They Needed?

Customers ask me for material selection recommendations all the time....

Can you use a Thermal Pad/Gap Pad more than Once?

My blogs largely originated from the various questions I have gotten from...

Ultem Film | PEI Film | Custom Die-Cut Electrical Insulator

NEDC manufactures ( by die cutting) electrical insulators/isolators for many customers. One of the more robust electrical insulators/isolator around is Ultem™, or PEI. Properties of Ultem/PEI Film Ultem/PEI is a thermoplastic material. Ultem™ offers high heat...

9485PC Adhesive Transfer Tape | 350 Acrylic Adhesive | Custom Die Cutting

NEDC laminates many tapes to many types of gasketing materials. However, not all tapes are just adhesive laminated onto a kraft liner, and done- some adhesives are reinforced with fiber to make them more manageable. One of the tapes that utilize these fibers is known...

Flame Retardant Adhesive Transfer Tape | Lamination, Die-Cutting

At NEDC, we stock a lot of materials that are flame retardant. In fact, we have a page that just mentions all the flame retardant materials we have. These include gasketing, thermal pads, absorbers, and other types of materials. One thing we have not mentioned on this...

Custom Dust Gaskets | Foam/Sponge Neoprene, Silicone, & PORON

At NEDC, as a gasket manufacturer we supply a number of different types of gaskets to our customers. When I’m discussing applications, one of my favorites is custom dust gaskets. The reason for this is because Dust Gaskets are usually some of the more simple gaskets....

Battery Cushion Pads | Soft Custom Pads | Foam, Sponge | Custom-Cut

At NEDC, we manufacture a lot of products. Battery Cushion Pads are a common product we make. Customers who are making a modular electronic, oftentimes have a battery that also requires cushioning, or thermal cooling. What are Battery Cushion Pads Used for? Battery...

Gap Pad 3000S30 aka GAP PAD TGP 3000 | Custom Thermal Pad

Thermal Pads are one of our most common products. Customers call all the time asking for recommendations on Gap Pad, or how to choose Gap pad products. There are a few products that I enjoy recommending. One of them is Thermal Pad Gap Pad 3000S30. Why Gap Pad 3000S30...

Low Temperature Silicone Gaskets | Pads | Custom Die-Cut Gasketing

Low temperature gaskets are something we've talked about before. One thing we have not discussed is low temperature silicone rubber gaskets. To be clear, these type gaskets are approaching the most extreme low gasketing material we offer at NEDC. This is because,...

Fishpaper/Vulcanized Fibre | Custom Die Cutting/Laser Cutting

At NEDC, insulators are one of our core products. Many different electrical insulation materials are among products we cut into custom shapes. However, fishpaper, and vulcanized fiber paper products are among the most popular electrical insulation materials we use. ...

ESD Gaskets | Neoprene/Silicone Gaskets, Pads | Custom Die-Cut

At NEDC, we manufacture gaskets, and custom pads. One of the more interesting materials offer is electrostatic dissipative(ESD) gasketing. Out of those materials we manufacture ESD Gaskets. What is ElectroStatic Dissipative Gasketing? It might be a good idea to start...

Low Surface Energy VHB Tapes | 3M VHB Tape LSE Series | Custom Die-Cut Tape

Low Surface Energy Materials are often hard to stick to. Conventionally for permanent fasteners that has been a problem when a tape would be more convenient and cost effective. With the addition of 3M LSE VHB Tapes, permanent fasteners are easier than ever. 3M LSE VHB...

Butyl Gaskets | Custom Die-Cut/Waterjet Cut Parts

Butyl rubber is an extremely versatile material. Butyl Rubber is a copolymer of isobutylene, and a very small amount of isoprene, both polymers are distributed throughout the polymer chain randomly. It was first synthesized in 1937 at Standard Oil, now formally...

Sil-Pad 980 aka SIL PAD TSP 1680 | Custom Die-Cut Shapes

At NEDC, we cut a whole bunch of different types of thermal pad gap filling materials. Sil-Pad 980 has a unique application list where it's used. Properties of SIL PAD TSP 1680, aka Sil-Pad 980 SIL PAD TSP 1680 has great cut-through resistance. It is silicone-based...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.