At NEDC, soft materials are our thing. Actually, soft silicone materials are our thing. These include gap filling pads, gasketing materials, and more. One of the common issues with sealing is the amount of compression force the application can allow.

Properties of BF-1000, BF-2000 Silicone Foam

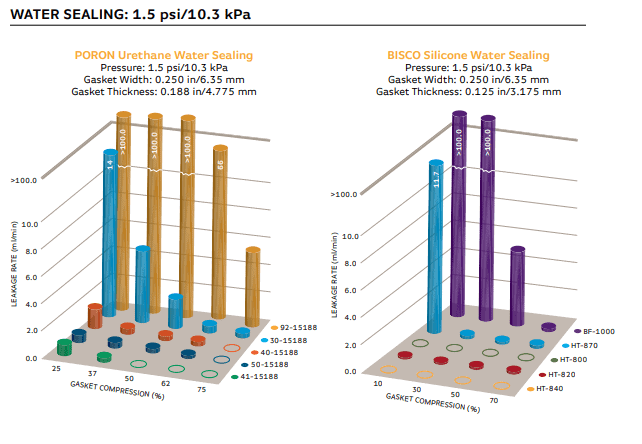

Rogers Corporation offers two different soft cellular silicone foam materials that are great for low force sealing. These low weight, and high softness materials combine to have great sealing properties for dust sealing. They are among the most soft silicone foam products available for die-cutting/converting. The foams offer the consistency of something akin to a soft pillow. They have an excellent memory, and low stress relaxation. This means their compression set is also extremely low. In addition, they are UV and ozone resistant. Applications include LCD screens, laptops and different portable electronics. Similar to most cellular silicone products, these materials feature great low, and high temperature resistance (-67° to 392°F). Both silicone foam products are UL 94 V0 rated. It is good to note that these foams do not do well for sealing water without major compression forces. The graph (lifted from Rogers Technical Sealing Guide) below illustrates this for BF-1000. Its hard to see – (the purple on the right is BF-1000).

Water Sealing Graphs

Table Below, Detailing Availability:

| Product | Manufacturer | CFD Range | Colors Available | Thicknesses Available | Density (lb./ft³) |

| BF-1000 | Rogers Corporation | 1-5 psi | White, Black, Gray | .063’’-1.00’’ | 12 |

| BF-2000 | Rogers Corporation | 2.5 psi max. | Black | 0.125’’-.500’’ | 11 |

More Details on Silicone Foam

The width of these materials is 36’’ wide. Naturally, these silicone foam materials are available with adhesive backing such as 3M 467MP, or 3M 9472. For more information on BF-1000, or BF-2000 from Rogers, please contact sales@nedc.com.