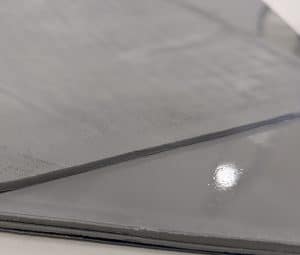

Gap Pad 7000ulm Thermal Pad Sheets

One of our core products at NEDC is thermal gap pads. Oftentimes when engineering a new thermal pad into a design, one of the key considerations along with thermal conductivity of the pad is the softness and compliance of it. How well the pad wets out onto the interface can make a huge impact on how well it conducts heat out of the application. There is a grouping of ultra-low modulus pads that help with this from Henkels’ Bergquist. These pads are the ULM(ultra low-modulus) group.

What Thermal Pads are these?

There are currently 4 thermal gap pads that make up the ultra-low modulus family of gap pads. All four pads are silicone based, and have the UL 94 V0 rating. These 4 thermal gap pads make up a family of pads that are very soft/complaint but also are high thermal conductivity thermal pads. The Young’s Modulus is giving below to give the reader an idea of how complaint these thermal pads are.

GAP PAD 3500ULM- 4 psi Young’s Modulus

Gap Pad 3500ULM is a 3.5 W/M-K gap filling pad that has an inherent tack on both sides. The natural tack provides ease of assembly in application. It features a low Young’s Modulus of 4 psi, making this pad extremely complaint. It comes in both a fiberglass, and non-fiberglass option. It is important to note that some thicknesses of Gap Pad 3500ULM are required to have fiberglass to make handling possible. Gap Pad 3500ULM comes in a refined gray color. Its available in thicknesses ranging from .020’’ to .125’’. GAP PAD 3500ULM is also known as GAP PAD TGP 3500ULM.

GAP PAD 6000ULM- 6 psi Young’s Modulus

Gap Pad 6000ULM is a high-performing 6 W/M-K gap filling pad that has an inherent tack on both sides. Similar to Gap Pad 3500ULM, this pad is extremely conformable with a Young’s Modulus of 6 psi. The thermal impedance numbers of this pad are really impressive, featuring .26 ºC-in2 /W at 30% deflection. This pad comes in a refined gray, and is available in thicknesses ranging from .040’’ to .125’’. Some thicknesses of GAP PAD 6000ULM require fiberglass for handling. GAP PAD 6000ULM is also known as GAP PAD TGP 6000ULM.

GAP PAD TGP 7000ULM- 22 psi Young’s Modulus

Gap Pad 7000ULM is a 7 W/M-K gap filling pad that is used in highly demanding thermal application that do not have the luxury of compression stress. Gap Pad TGP 7000ULM is a high thermal conductivity thermal pad that is used in many high performing applications such as optical transceivers, and telecommunications. This material is essentially a putty in pad form- being extremely impressionable and highly complaint. It is good to note this material is only available in 8’’ x 8’’ sheets when designing in to an application. Gap Pad TGP 7000ULM is available in thicknesses ranging from .040’’ to .125’’.

GAP PAD TGP 10000ULM- 25 psi Young’s Modulus

The newest addition to the ultra-low modulus family is Gap Pad TGP 10000ULM. Gap Pad TGP 10000ULM has the highest thermal conductivity pad to date in the Bergquist line-up. This high thermal conductivity gap pad reaches to a mind-bending 10 W/M-K performance for low compression applications that require high amounts of thermal conductivity. This pad has a Young’s Modulus of 10 psi. This pad comes in thicknesses ranging from .040’’ to .125’’. It also comes in a refined gray color. It is good to note this material is only available in 8’’ x 8’’ sheets when designing in to an application.

Cutting of Thermal Pads

In conclusion, NEDC sells or converts high thermal conductivity thermal pads for its customer. NEDC die-cuts, or otherwise converts Gap Pad sheets into finished Gap Pad preforms for applications. For more information on thermal gap filling pads, or you believe you have an application that could utilize one of these pads, please contact sales@nedc.com.