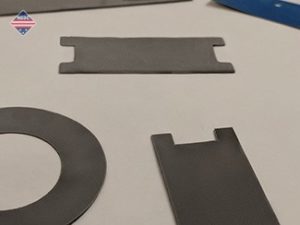

Die-cut assortment of Gap Pad 3500ULM

Over the years the Henkel Company has developed thermal management solutions for many different types of applications. In some applications, the stress is not high enough to utilize traditional Gap Pads. In cases like these, Henkel Company has developed a thermal management product that may be suitable for low stress, high heat applications. This putty like Gap Pad is helpful in a wide variety of applications.

Why Gap Pad 3500ULM? Whats different about this Gap Pad?

Gap Pad 3500ULM is an ultra-low modulus material designed for thermal situations where electronics produce heat, and require a low-stress material. This material has a low modulus which means little stress must be applied to yield a deformation of the material. This can be helpful in thermal applications in order for the Gap Pad to easily wet out onto surfaces without much pressure. Despite Gap Pad 3500ULM’s strong, yet yieldable structure, it still features a high level of thermal conductivity, reaching as high as 3.5 W/m-K, hence “3500”. For this reason it is often used in applications that require low stress yet high conductivity, such as adhering a FET to a heat spreader.

While Gap Pad 3500ULM can facilitate a solution to generic issues, it is also capable of solving thermal management problems in custom applications. Gap Pad 3500ULM’s suitability for many applications is heightened by its incredible performance on a number of attributes including a wide temperature range, electrical isolation, and flammability ratings. Like many other Henkel products, this product features the stringent UL 94 V0 rating. This is significant considering the diverse functionality the Gap Pad offers. The availability of Henkel’s Gap Pad 3500ULM is about as diverse as the product’s properties.

Availability/Fiberglass or No Fiberglass?

There are a number of configurations available with this material. These range from tacky both sides to tacky only on one side, and can have fiberglass or no fiberglass. The different formats can be helpful in different applications. The natural color of this material is a refined gray. The Gap Pad is available in thicknesses ranging from .020” to .125” thick. Since NEDC is a converter, we offer these solutions die-cut and waterjet cut. For more information regarding Gap Pad 3500ULM or you have an application you believe could utilize this thermal solution please contact sales@nedc.com.