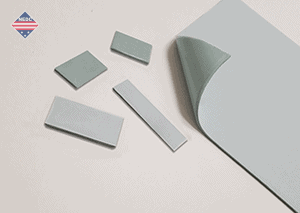

Gap Pad® 5000S35, die-cuts, and sheet

NEDC has a number of popular products that it consistently converts through die cutting and waterjet cutting. Since no two pieces of metal will ever match up perfectly, Henkel offers a conformable line of products that will, called Gap Pad®. One of the most popular gap filling materials is Gap Pad® 5000S35 through Bergquist, a Henkel Company. The benefits, and features of Gap Pad® 5000S35 give heft to the popularity of the product. Gap Pad® 5000S35 features a convenient way to build thicknesses while maintaining high thermal conductivity, great surface topography conformability, and great physical properties.

Properties of Gap Pad 5000S35

This material features a fiberglass reinforced polymer, in order to resist tears and punctures during assembly and afterwards. The fiberglass also has the added benefit of electrical isolation. It has a low hardness of 35 on the Shore OO scale, easily filling gaps. It also exhibits a high thermal conductivity, reaching a typical value of 5 W/m-k. This metric is the highest thermal conductivity in the Gap Pad® family. This is significant because of the applications Gap Pads are normally used in, requiring high thermal conductivity. It performs well even under low pressured systems. GP5000S35 also carries an incredible fire performance rating of UL 94 VO, one of the most stringent of the standard. In addition, GP5000S35 is part of the S-Class of Gap Pads. This Gap Pad® exhibits great natural tack on both sides of the product, allowing the material to naturally fill gaps such as air bubbles.

Availability/Nomenclature

Filling in these air bubbles will reduce thermal resistance. The top layer of the material has less tack to help facilitate assembly. GP5000S35 is available in the color of an elegant light green. The thicknesses of GP5000S35 range from .020” all the way to .125” thick. These thicknesses are important in order for the gap filler to have the ability to build to the heat sink. Naturally an increase in thermal impedance is apparent as the thickness increases. For more information on this, please see the Bergquist website. Gap Pad® 5000S35 is also known by GAP PAD TGP 5000. If you have an application that requires a die cut thermal gap pad material such as Gap Pad® 5000S35 please contact sales@nedc.com.