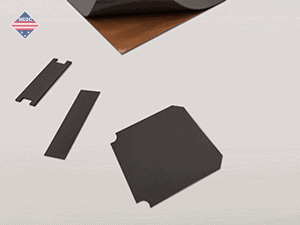

Microwave Absorber die-cuts and waterjet cuts/sheet with PSA

There are many types of microwave absorbers, however for our purposes, this article focuses on rubber sheet absorbers. These materials usually have a few components, the first being the rubber. Silicone rubber is one of the most common materials used in absorbers because of its high temperature resistance. Many different elastomer matrix configurations are available for different application requirements, such as temperature, chemicals, flame resistance, and more. Viton, Nitrile, and Urethane are some other elastomers that are typically available for microwave absorbers.

The other component is the filler. Microwave absorbers have high magnetic permeability, constructed from magnetic flakes that are placed within the material, to ensure waves are attenuated properly. These absorbers are typically used in circuit board covers to reduce cavity resonance. They are strategically placed throughout the cavity to eliminate crosstalk and attenuate resonances. The absorbers reduce the stored energy in the cavity, thus reducing the Q (quality factor). After strategic placement of the absorbers, circuit performance should be improved. Microwave absorbers are nonconductive to ensure circuits will not be shorted. Typically, the microwave absorbers frequency absorbing range spans from hundreds of MHz to multiple GHz. Microwave absorbers are available in discrete and broadband frequencies. Microwave absorbers are used in countless electronics, including wireless LAN devices, cellphones, laptops, tablets, and other electronic applications.

Oftentimes, PSA is required with an absorber so they can be adhered onto a substrate with ease. Typically, acrylic is the adhesive of choice for these applications because of cost and because the absorber is normally sticking to a metal substrate. NEDC often waterjet-cuts and die-cuts microwave absorbers with or without PSA. For more information on microwave absorbers please contact sales@nedc.com.