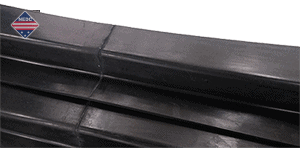

Large Neoprene® Gasket Bonding

In the 1970’s the US military launched a new class of aircraft carriers called the Nimitz. It was the biggest class yet, offering gigantic load displacements and great sustainability over long periods of time. Similiar to then, large machines require large parts, and NEDC is very familiar with large gasket manufacturing through various methods.

Why are Gaskets big, and how big can they get?

The majority of the business that NEDC does is the manufacturing of small, to medium size gaskets. Nevertheless, it is not outside NEDC’s scope to manufacture gigantic custom gaskets. There are several types of materials that NEDC utilizes when manufacturing gaskets, ranging from regular gasketing rubber materials to EMI/RFI shielding components. Often it is not feasible to offer a regular die cut gasket that has a huge size; the same goes for waterjet, or laser cut parts without running into constraints of material size. Unfortunately this is not always true when the material simply is not available that big, or that wide.

What is a Big Custom Gasket?

To answer this question properly, its really best to describe them through types of materials. For example, Neoprene Sponge materials typically come in a 72” sheet.. so waterjet cutting one gasket is:

A. Feasible because the bed is that big.

B. Not cost prohibitive because truthfully, most Neoprene Sponge materials are not that expensive.

As a second example, take Electrically Conductive Fluorosilicone materials. The sheets can come in a variety of sizes, but 20” x 30” is usually the biggest size. So waterjet cutting one gasket is:

A. Feasible because the bed is that big.

B. Super cost prohibitive because consuming one whole sheet for a frame gasket, can be upwards of $3,000. See our blog on affordability suggestions for electrically conductive gasketing materials.

Recently, NEDC manufactured an EMI/RFI shielding electrically conductive fluorosilicone ladder gasket that was over 25” inches long. For this type of part, it is rather rare to manufacture a part this big. As another example, the other day, NEDC shipped a 14′ gasket to a customer.

Methods of Manufacturing Giant/Large Custom Gaskets

After 30 years of experience in the gasket manufacturing industry, NEDC has developed methods for working around these types of everyday issues. Some of the problem solving techniques NEDC have adapted are:

- Cold Bonding

- Vulcanizing

- Sewing/Knitting

NEDC can provide many types of seams, including a 45 degree seam, a dove-tail seam, and more. These bonds are made through coordinated efforts between adhesives, RTVs, and our skilled fabricators. These techniques provide the ability to supply gaskets in an extra-large size, despite the constraints of the size of materials. NEDC maintains vulcanizing capabilities in house, so manufacturing large size gaskets has become relatively easier. There are a few caveats to keep in mind with larger than normal gaskets:

- Tolerancing can become a challenge. A tolerance of +/- .005” may not be realistic in a gasket that is 70” long. It is good to keep in mind that the larger the gasket, the larger the tolerance should be.

- Bonding/Vulcanizing/Knitting will require the drawing to allow for a seam.

- With very expensive materials bonding/vulcanizing can become economic, if more parts can be nested out of a sheet of expensive material.

More Information

If you have a gasket that you believe could be manufactured but is too big for conventional means, please contact sales@nedc.com.