Waterjet Cutting

Foam, Solid Gaskets, Thermal Pads, Absorbers, and Electrical Insulators

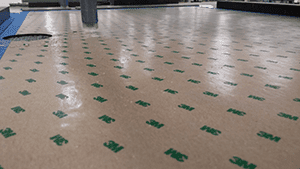

Waterjet Cutting PSA-backed Neoprene Gasket

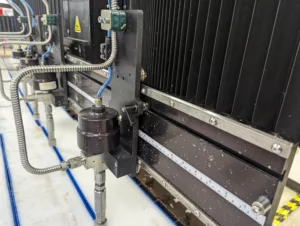

NEDC operates only with state-of-the-art equipment that can handle a wide variety of materials. One of the most sophisticated machines NEDC owns is our Waterjet Cutters. Waterjet Cutting happens through a very unique process. The process starts with a high-powered pump that creates a lot of pressure for the water. The water then exits the head of the waterjet through a premounted sapphire/diamond orifice. All of this action produces an extremely powerful waterjet stream that is forced from the head at incredible speeds, (30,000-50,000psi). This streams pierces the gasketing material creating a clean cut with the most available commodity on the planet, water. The waterjet cutting process allows parts to be nested in a very economical fashion. NEDC is a leading waterjet cutting supplier for gaskets, insulators, and other elastomeric products such as thermal filler pads, or absorbers.

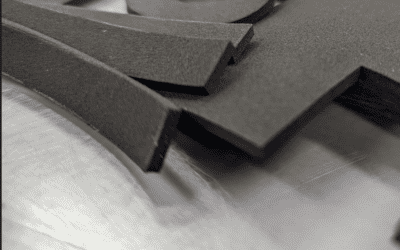

Foam/Sponge Gaskets:

Foam or Sponge gaskets are also cut with our waterjet machine. These materials can be flexible and cause issues in conventional die-cutting. This is due to the elastic nature of these materials; causing the material to snap-back into an hourglass like shape. However, with a waterjet focusing on one hole/feature/cut at a time, meeting tolerance requirements becomes easier.

Solid Rubber Gaskets:

At NEDC, the main function of our waterjet is used to cut solid gaskets. These gaskets can range from nitrile rubber, to neoprene rubber. The reason we do this is because typically when our customer is looking for a few gaskets, we can make them quickly and accurately on our waterjet. It also helps us dial in tight tolerances. Some of these materials include neoprene, fluorosilicone, silicone, nitrile, EPDM, or other conventional rubber materials.

butyl custom gaskets

Advantages of a Waterjet Cutting Machine:

- Extremely Accurate Cuts of Complex Parts

Waterjet cutting offers an incredible amount of accuracy through a coordination of computer software and tight controls. Tolerance can be held as +/- .002” on some materials.

- Maximizes Yield of material through nesting software

Parts can be easily nested to offer our customer the best price possible. In some situations, when a part has a very unique geometry, sometimes the way it may be nested is not quite as linear as a simple horseshoe like part. In these cases, waterjet machines are able to flip, turn, and match the shape in many different directions utilizing every inch of material.

- No tool investment is necessary for water jet cutting

No tool is needed to be made, the DXF is the tool! Please provide an electronic file to aid in programming/cutting. This saves time and money because this file is cut to your specifications.

- Quick Prototypes

At NEDC, we strive to provide prototypes quickly. Waterjet Cutting offers the advantage of the customer being able to engineer the part through their DXF and see what the part will look like in production. The benefit of creating a DXF gives a side benefit of being able to move into production in a much quicker fashion by reducing the time between each prototype rendition. No tool is required to be created, so parts can be cut extremely fast.

- Cut parts from CAD/DXF files, to ensure perfect accuracy of every cut, every time. High degree of repeatability

The DXF is executed by the software in the waterjet cutting machine. When cutting with a DXF file, you can guarantee that no tool will wear/abrade. The waterjet stream itself is always offering a consistent water stream that makes each part nearly identical to the last. This makes reproducibility a huge asset for the machine.

- Allows materials to be cut without the typical compression of conventional die-cutting

Die-Cutting thick foam/sponge materials can result in concavity because of the “burst” action of the die; with a waterjet it is possible to avoid this compression distortion because the waterjet is not compressing the material in the way a conventional die cutting operation would. The difference is, it is slicing through the material in a vertical direction.

- Size of gaskets/parts has little limitations

Cutting gaskets has nearly no limitations when it comes to custom. However, size becomes a concern the bigger the gasket becomes. With waterjet cutting, the only limitation becomes the size of the bed of the waterjet itself. With that said, NEDC has cut 7 foot gaskets before on its waterjet machine.

waterjet cut sponge/foams

Limitations of a Waterjet Cutting Machine:

- Size of parts have limitations

While we just said above that bigger gaskets are easier to cut with a waterjet- as it gets smaller, it may become more difficult. This is because the waterjet stream has a size too, and that starts to limit the features it can cut with accuracy. If the stream and the feature become competitive in size, it can become a challenge.

- Amount of parts being cut

While waterjet cutting is pretty quick, the amount of parts being cut can become a challenge because as mentioned above, cutting with a waterjet only works on one feature at a time. This is in comparison to die-cutting that cuts everything all at once. This is one of the tradeoffs when using a waterjet cutting machine. This drawback generally falls under speed of the overall process.

- Some materials just do not work

Some materials just do not cut well on a waterjet. Fibrous, or otherwise paper like products generally have a tough time cutting because either they soak up the water or they explode when cutting them. Other materials that we know do not work is anything that is impregnanted with wire in a perpendicular direction to the material. It is wise to consult with an experienced waterjet operator before asking a part to be waterjet.

If you have a gasket/part that you believe could be waterjet cut, please send your question or drawing to sales@nedc.com. NEDC has experienced waterjet operators that understand what the machine can do well.

Waterjet Cutting Blog

Are Electrically Conductive Gaskets, Thermally Conductive ? | A Test Analysis

Recently, we procured a thermal performance testing machine. I thought it’d be fun to test what EMI/RFI gasketing thermal conductivity is(I’ve been testing everything I can get my paws on, haha). In this test, we decided to measure the thermal conductivity/thermal...

Previous Posts

Silicone Rubber Gasketing, Peroxide vs. Platinum Cured

Customers buy all sorts of silicone rubber gaskets. In fact, silicone...

Why Commercial EMI/RFI Gasketing | Custom Die-Cut EMI Gaskets

At NEDC, we sell gaskets, lots of them. I would love nothing better than...

LOCTITE® Thermstrate 2000 aka TCF 1000AL | Die-Cutting/Converting

At this point, I’ve written 250 blogs on this website- I know, I am even...

Cooking an Egg Through a Thermal Pad | How they Work

At NEDC, we cut thermal pads like it's our job- cause guess what.. It is. Oftentimes, when we are talking to customers- they may not know exactly how thermal pads work because it may not be obvious what a good insulator air is in an application. A few weeks ago, right...

VHB GPH Tape | Powder Coated/Liquid Painting | Die-Cut Tape

NEDC is a major supplier of 3M VHB Tape. There are VHB Tapes for all sorts of applications. However, it is well known in the industry that sticking things to powder coat, and liquid painted surfaces can be very tricky. Considering this, 3M Company has come up with a...

Silicone Sponge vs. Silicone Foam | Whats the Differences? Are they different?

We see on prints all the time “R10480S Silicone Foam” or “HT-800 Silicone Sponge”. Its clear what the customer is requiring. However- these requirements are slightly incorrect. It should read “R10480S Silicone Sponge” and “HT-800 Silicone Foam”. WIth that said, when I...

Speaker Gaskets | Custom Die-Cut Shapes | Foam/Sponge/Cork

Speakers are everywhere these days. I have some in my car, I have two on my desk (currently playing Vivaldi). In our last blog, we talked about rattling/pinging that can be present in different environments. As discussed in that blog, we suggest foam/sponge to absorb...

Foams/Sponges to Stop Rattling/Pinging/Buzzing in Applications

A few years ago, I had a car that had a sunglasses holder near the sunroof. I’m not going to name the manufacturer because I’m never buying a car from them again- however- One day(don’t ask me why, it started rattling).. It made this all the time. Finally, after a...

Sil-Pad A2000 aka SIL PAD TSP A3000 | Custom Die-Cut Thermal Pads

At NEDC, we die-cut a lot of thermal interface materials (TIMs). Cost is always a concern when customers are selecting thermal pads. When selecting an .015’’-.020’’ thin thermal pad, Sil-Pad A2000 is a good choice. Why Select Thermal Interface Pad Sil-Pad A2000? I’m...

Thermal Pad Sample Kit 2.0 | Sil-Pad & Gap Pad in One Kit

During COVID, NEDC released a Thermal Pad Sample Kit. It had a number of Gap Pads on it. We decided to re-release it- new. and improved. Why Thermal Pad Sample Kit 2.0? This time it has a combination of Sil-Pad and Gap Pad on the Thermal Pad Sample Kit. It has...

Electrical Enclosure Gaskets | Custom Die-Cut | Silicone, Neoprene

At NEDC, we make gaskets for all types of projects. One of the most common types of gaskets we make is something we call enclosure gaskets. We call them electrical enclosure gaskets here because oftentimes the enclosures that we are sealing off house electrical...

3M Thermal Interface Pads | Silicone – Acrylic | Die-Cut Thermal Pads

At NEDC, we cut thermal pads on a frequent basis. Customers come all the time, asking for a thermal interface pad for their special electronic, phone this, defense system that. With all of these commercial electronics, and military applications, you need a reliable,...

PORON® Condux Plus™ | Custom Waterjet Cutting/Die Cutting Shapes

At NEDC, we cut a lot of conductive foam for customers. One of the conductive foams that we have a lot of success with is PORON® Condux Plus™. There are many reasons for this, but the below are a highlighted few I thought I’d share. Uses for PORON® Condux Plus™...

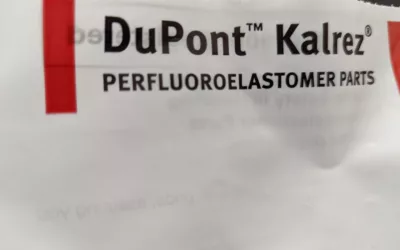

Kalrez Perfluoroelastomer | Custom Die-Cut Parts

At NEDC, we have many materials to choose from when a customer discusses an application. For todays blog, I thought I’d write about an extreme material. Why Choose Kalrez® Perfluoroelastomer? The answer to this one is simple. If you have an application that requires...

Membrane Switch Spacers | Custom Die Cut/Laser-Cut Shapes

If you open up a membrane switch, you will find there are 3M products all over the place. 3M 467MP, 3M 467MP liner- any die-cutter who is worth their weight knows 3M 467MP is a commercial staple for this reason. NEDC provides all sorts of insulators, and spacers for...

All of the information presented above is believed to be factual and accurate; however, NEDC is not liable for any design or application utilizing this information.

New England Die Cutting

Capabilities/Products

Quick Links

Popular Blog Posts

Sil-Pad or Gap Pad?

It is easy to understand why the applications of Gap Pad and Sil-Pad can be confused. This is because both thermal pads have a lot of similarities. For the most part Sil-Pads and Gap Pads are electrically isolating. Both thermal pads are thermally conductive, and both...