I always make the analogy that thermal pads are like ice-cream, there’s something for everybody. In this blog, I wanted to discuss some of the qualities of thermal pads that are available but not as sought after or not preferred as some of the other qualities. The typical thermal pad to me is typically electrically isolating, has as high thermal conductivity as possible, and super-soft. There’s other gap filling pads available that have qualities that are not always desired, but there is someone looking for them!

sil-pad 1500st, gap pad 1000hd

High Durability

Thermal Pads with good durability are common. This comes from the reinforcements such as fiberglass, PET, and other tough materials. However, Gap Pad 1000HD stands above the rest when it comes to durability. This material is tear resistant, and puncture resistant while maintaining good thermal conductivity and low thermal impedance. Gap Pad 1000HD features a polyimide reinforcement carrier that makes it good for tough applications. They may require a lot of rework or sharp objects. In addition, Gap Pad 1000HD aka Gap Pad TGP 1000HD has a thermal conductivity of 1 W/m-K. This thermal pad is available from .020’’ to .125’’ in thickness.

Non-Electrically Isolating

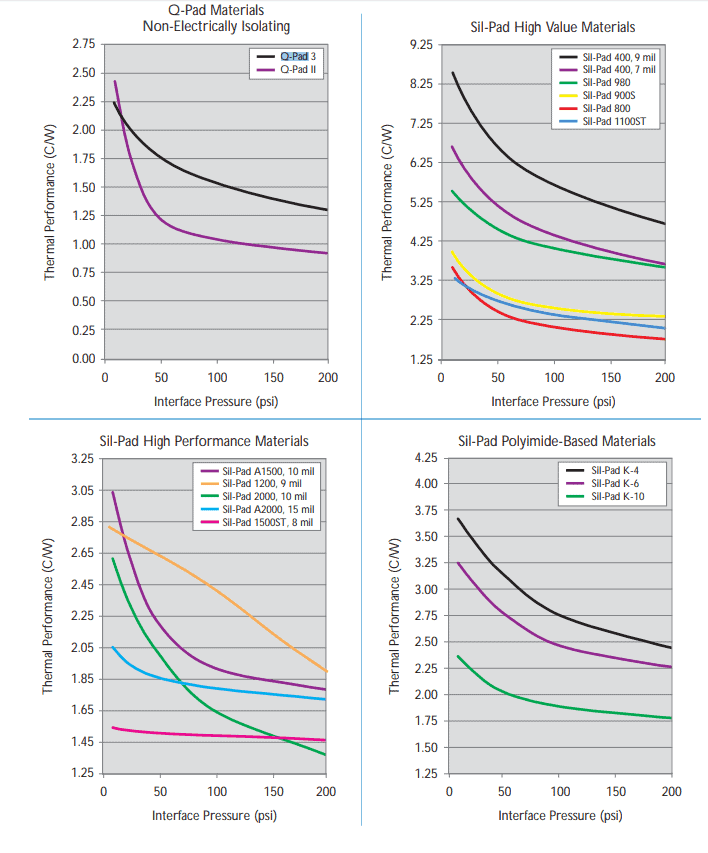

The Q-Pad series are high-performing thermal pads. They feature some of the highest thermal conductivity, and lowest thermal impedance available(see graph below for details) of the thin thermal pads available. The one caveat is they are not electrically isolating. Q-Pad II(.006), and Q-Pad III(.005) are the thermal pads that are available for this type of thermal pad. Q-Pad II is an aluminum reinforcement carrier, while Q-Pad III is a fiberglass reinforcement carrier. Both these materials are available with tape backing for ease in assembly. Respectively, they have a 2.5 W/m-K and a 2.0 W/m-K thermal conductivity.

Thin Pads with Soft-Tack

The family of Soft-Tacks thin thermal pads are the “ST” (soft-tack) Sil-Pads. These include: Sil-Pad 1500ST, and Sil-Pad 1100ST. Both of these pads are able to perform at an extremely high thermal performance level. This “soft-tack” enables the material to do a better job wetting out onto surfaces while maintaining great thermal conductivity. These thermal pads end up providing low thermal impedance. Of course, they do not come with tape availability because this would interfere with their great thermal performance!

NEDC die-cuts or otherwise converts thermal pads into custom shaped thermal pads. For more information on thermal pads, or you think you have an application that could utilize a thermal interface pad, please contact sales@nedc.com.

The graph is re-presented from the Sil-Pad Selection Guide

Technical Data

Gap Pad 1000HD Datasheet Download

Sil-Pad 1500ST Datasheet Download