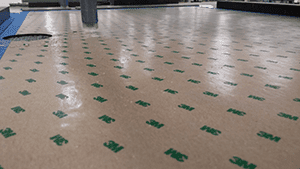

Waterjet Cutting PSA-backed Neoprene Gasket

Some tools seem to be able to do everything. These are the tools of our lives that we feel are tried and true, and which work in almost every situation that may cross your path. In the manufacturing industry, one machine is set apart from the rest. This machine is the waterjet. Waterjet cutting had its advent in the 1930s, and evolved from primitive machines that had been primarily used to cut paper.

In this spirit, as NEDC has evolved, we have also evolved our cutting methods. These new cutting methods were realized when NEDC purchased their first waterjet nearly a decade ago. NEDC realized that waterjet cutting had become one of the most versatile cutting methods in the converting industry. Keeping with the company’s commitment to cutting edge technology, we made the investment early.

Benefits of Waterjet Cutting over other Methods

The waterjet offers benefits over many conventional methods. This mainly originates from the diversity of materials that it can cut. While machining, laser cutting, milling, or punch pressing are reliable converting methods, the waterjet can cut an extreme range of materials. These materials range from extremely hard metals to highly conformable elastomeric materials, such as 20A durometer rubber for gaskets. Some examples of the materials that we have seen waterjets cut are:

- Polyurethane Foam

- Aluminum

- Neoprene

- Steel

While some cutting methods are challenged by thickness of materials, the waterjet typically is not. For example, normal punch pressing or die cutting can be hindered or halted by excessively thick materials. Waterjet cutting is able to consistently return high quality parts when material is excessively thick, with very few exceptions.

While waterjet cutting can convert a wide range of products and materials, it also offers the added bonus of little setup time and no-tooling. Oftentimes with die-cutting or punching, a tool will be required. Waterjet cutting offers the benefit of tool-less cutting, which NEDC can offer to customers for price reductions.

Many times setting up a machine to operate can be the most costly part of manufacturing. In comparison to some other conventional methods such as milling, time-consuming setups can be easily avoided. A waterjet can be set up in as little as two minutes; if the operator has the appropriate experience. As a result of the waterjet’s easy setup and lack of tooling requirements, it is extremely versatile in making prototypes for a customer that needs a quick turn part. (See our prototyping page for more information.)

How it Works/More Info

What adds to the versatility of waterjet cutting is the added complement of user-friendly technology. While some converting techniques still require manual hands-on work, waterjet cutting has basically always revolved around the universal DXF/CAD file. The electronic compatibility of waterjet cutting continues to add to the exactness that a dimensioned electronic file can offer. When parts demand tight tolerances, waterjet cutting can answer. The tight tolerancing a waterjet can offer is typically not limited by amount of holes or tricky geometry. This is because waterjet cutting focuses on one piece at a time, dissimilar to die cutting. Of course there are exceptions for everything, and there are times that the waterjet machine can be challenged by complexity. For more information on waterjet cutting, or if you have a part you think would be a good fit for our waterjet, please contact sales@nedc.com.