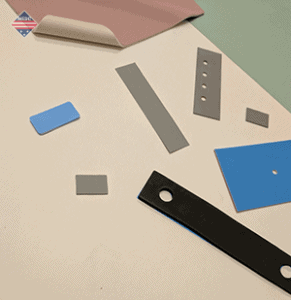

Gap Pad and Sil-Pad Die-cuts

It is easy to understand why the applications of Gap Pad and Sil-Pad can be confused. This is because both thermal pads have a lot of similarities. For the most part Sil-Pads and Gap Pads are electrically isolating. Both thermal pads are thermally conductive, and both are normally put between two interfaces to conduct heat in the Z direction.

Common Thermal Ground

While both pads have a lot of similarities, they also have a lot of differences. It is important to note that Gap Pad and Sil-Pad do sometimes have overlapping applications, where both may work. An example of overlapping applications may arise when the thicknesses cross at around .010”-.015”- commonly Sil-Pads are available around these thicknesses, with some Gap Pads being available as low as .010” in thickness. In general, there is a hierarchy of requirements to check off when determining whether Sil-Pad or Gap Pad would be best. It is important to start with bond line thicknesses at maximum application pressure to determine which pad is most fitting. After determining that, move on to electrical requirements, and finally thermal requirements.

Sil-Pad Differences

Generally, Sil-Pad strength is accentuated by how it is mounted. Oftentimes, a Sil-Pad is thinner, and more mechanically durable than a Gap Pad. For this reason, Sil-Pads are often seen in applications that have more torque from screws or rivets. Sil-Pads are also generally used in applications where clips or screws are used. Sil-Pads are available with pressure-sensitive adhesive for assembling ease. While PSA does not significantly reduce thermal performance at thinner thicknesses, it still does affect it negatively. In addition, generally Sil-Pads are harder materials that are less conformable than their Gap Pad counterparts. For example, Sil-Pad 2000 has a hardness value of 90 Shore A, while Gap Pad HC3.0 has a much lower hardness of 15 Shore 00. Also, Sil-Pads are used in situations in which cut-through resistance may be a concern. For this reason, Sil-Pad products have different reinforcement carriers such as polyimide or fiberglass.

Gap Pad Differences

Gap Pads inherently are meant to fill a gap to allow better thermal conductivity than dormant air. Gap Pads are extremely conformable, allowing them to fill in air gaps that are commonplace in heat sinks and electronics. They are rarely mounted with clips, but instead placed in their proper position. The majority of Gap Pads are provided with natural tack on each side. For this reason, the natural tack can be particularly handy in general use during assembly. Gap Pad strength is accentuated by conformability, and thermal conductivity instead of mounting & pressure. Since thermal conductivity is the primary interest when using Gap Pads, it is wise to avoid using thermally-impeding adhesives if they are not necessary. The line between Gap Pad and Sil-Pad can sometimes be nuanced, but testing should always provide the answer of which pad will best serve the application.

More Info..

Regardless of the application, NEDC converts many different types of thermal management materials (TIMs) through die-cutting and waterjet cutting capabilities. For more information on Gap Pad or Sil-Pad or other thermal management materials, please contact sales@nedc.com.