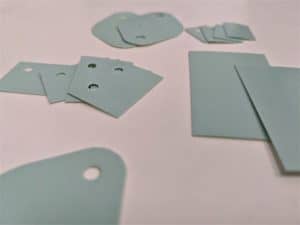

hi-flow 625ac die-cut

At NEDC we are a custom manufacturer of thermal interface pads. Many of these gap filling thermal pads are used to remove heat out of the application. PCM materials offer an advantage that other thermal interface products cannot seem to do. Phase Change Materials work by hitting a certain temperature – ( its phase change temperature ) at that temperature it turns to a liquid or gel like consistency. At this point, the material is able to make good contact with the interface because of its new level of viscosity.

Drawbacks of Other Thermal Interface Products

Thermal Greases are non-curing, so long term performance and reliability can be an issue. Thermal Gap Pads are cured, but they are offered for thicker cross sections. Contact, and wetting can be a difficult issue to solve at the thinner cross-sections. With Phase Change Materials those problems are solved. Typical with most thermal interface products, with PCMs, mechanical fasteners such as spring clips are required for good contact. Although fasteners are required, these materials can offer great thermal performance. It is good to keep in mind that not all PCMs are electrically isolating. However, many are. Oftentimes the way electrical isolation is achieved is through the carrier materials used. Some of these carriers include polyimide, or PEN film.

Advantages of Phase Change Materials

-Easy to apply because of their solid state

-They feature great thermal performance through thermal cycles

-Great thermal stability

-Non-Curing

-Excellent contact/wetting

–Low Thermal Impedance

-Thin Cross Sections

Options Available For Phase Change Thermal Pads

Legacy name/reinforcement carrier/New Product #

Isostrate-polyimide -EIF1000

Thermstrate-aluminum- TCF1000

Hi-Flow® 300P- polyimide- HI-FLOW THF 1600P

Hi-Flow® 225F-AC- aluminum- Hi-FLOW THF 1000F-AC

Hi-Flow® 105- aluminum- HI-FLOW THF 900

Hi-Flow® 625- PEN Film – HI-FLOW THF 500

Hi-Flow® 650P- polyimide – HI-FLOW THF 1500P

Some Phase Change Materials come with a PSA backing for ease in assembly.

Are PCMs Reworkable?

The short answer is Maybe. Once the phase change material has gone through one phase change it will normally adhere well to both surfaces. However, if it has not phase changed, typically the PSA backings with these materials are tacky enough to adhere, but also able to be reworked. Phase Change Materials are not tacky to the touch, so rework is easy.

More Information on Die Cutting

NEDC die-cuts or otherwise converts phase change materials into finished thermal pad preforms. For more information on anything above, please contact sales@nedc.com.