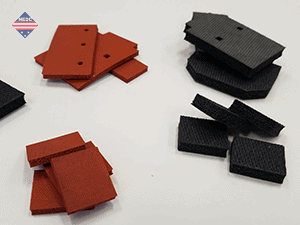

Open Cell Neoprene and Closed Cell Sponge Gaskets

It is estimated that the human body has over 37.2 trillion cells. The sum of the cells make the human body a true functional miracle. Just like humans, rubber may have cells too. But just as humans have different types of cells, sponge and foam can have different types of cells. These cells are usually opened, or closed cells or perhaps somewhere in between. The difference between closed cell, and open cell is not that difficult to understand. It is important to realize that both types of cell matrix structure are used in expanded rubbers, but they each serve different purposes.

Open Cell Sponge/Foam Rubbers

Open Cell Sponge/Foam Rubber is a type of material that bears its name from the fact its cells are “open”. This essentially means that while the rubber has cells, these cells are open to intrusion by other cells, and sometimes to the surface. This can be reduced dramatically when a “skin” on the surface is provided. The cells are interconnected within the rubber which give the material some beneficial properties. These properties can include great compression set, and resistance to stress relaxation. The drawback of open cell sponge/foam materials is the lack of resistance to mediums such as water (in an uncompressed state). This can be useful in situations where water absorption is desired, such as a “kitchen sponge.” In some instances, compressing the material may actually produce a sealing medium. Obviously, while sealing can occur if a open cell material is compressed, it is not recommended for application(s) that are immersed in water permanently, or temporarily, such as an IP medium-high water ingress ratings. Some commonly-seen open cell materials are neoprene, and natural rubber sponge.

Closed Cell Sponge/Foam Rubber

Closed Cell Sponge/Foam Rubber is essentially the opposite of open cell. While these materials have cells as well, these cells have formed their own independent cells that are resistant to the intrusion of mediums such as water. The fact the closed cell materials have independent cells, give this type of material more resistance to ingress of mediums such as gases and liquids. For this reason closed cell sponges/foams are used in applications requiring resistance to water, such as NEMA enclosures. The drawback of closed cell materials is that while the gases are what creates the resilient material, the gases (typically nitrogen) will seep out of the material over time with compression and decompression cycles. In general, it is better to go with a closed cell material in applications where penetrating liquids will be a concern. There is some debate on how to define “closed” cell but generally a water absorption of less than 5% can be considered closed.

Specifications and Definitions

Some of the material specifications draw a fine line between open cell sponge and closed cell sponge, such as ASTM D1056 (formerly MIL-R-46089). ASTM D1056 sets out different types: Type 1 (Open Cell), and Type 2 (Closed Cell). ASTM D6576 (formerly MIL-R-6130) has the same type 1, and type 2, open and closed cell respectively. These specifications are clear for separating the two because of the sharp differences. It is also good to note that it is often the case that some materials are not available open celled, such as fluorosilicone sponge, or silicone sponge.

Both open, and closed cell materials can be provided with a skin surface. Usually this skin is a fabric finish or a molded skin. If you have any questions about the different materials NEDC can offer converted (die-cut, waterjet cut, fabricated), please contact sales@nedc.com.