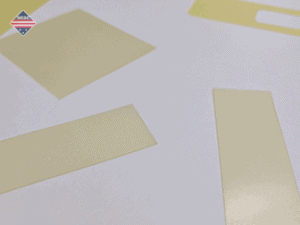

Die-cut Epoxyglass

As mentioned in many of the blogs we post, NEDC converts a lot of materials into custom shapes and sizes. Some of these materials can have multiple functions depending on the shape and orientation they are cut into. Some of the materials that NEDC die-cuts with many different applications are laminate materials such as G10 and FR4.

Benefits/Nomenclatures of Epoxyglass G10/FR4

These two materials are probably the most common laminate materials that NEDC works with. These two materials are usually bought to a common military specification, MIL-I-24768. /2 indicates a non-flame retardant epoxy fiberglass laminate, and /27 indicates a flame retardant epoxy fiberglass laminate. In industry, normally G10 refers to non-halogenated epoxy fiberglass, while FR4 refers to a flame retardant version imparted through halogens. These material’s benefits include elevated temperature ranges, great electrical properties, dependable thicknesses, and fantastic mechanical qualities. For these reasons, these materials are often used as shims and as electrical insulators in different applications. However, since NEDC commonly die-cuts these materials, tolerancing must be generous, and cut-outs limited. Depending on the requirements, NEDC is able to procure G10 and FR4 materials from different manufacturers in industry. This is because die-cutting has to break through the material completely in order to “cut” it. Above is a few pictures of die-cut parts of G10, and FR4 laminates.

More Information/Availability of G10/FR4

G10 and FR4 can come in a variety of thicknesses in sheet form ranging from .003” to 2.000” However, NEDC normally deals with nominal thicknesses stopping at 1/16”. NEDC often die-cuts these two materials into custom shapes for our customers. We can offer these with or without adhesive backing to make assembly easier for the end-user. For more information on custom die-cut laminates please contact sales@nedc.com.