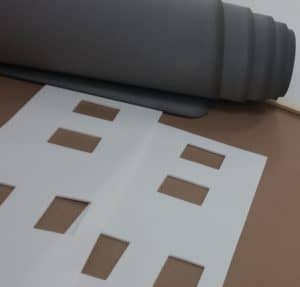

crosslinked polyethylene foam gasket

At NEDC we die-cut many different types of foam products. One of the more common foams we cut is crosslinked polyethylene foam(XLPE). XLPE foam is an abbreviation for crosslinked polyethylene foam. Gasketing is one of the main ways we use this material.

Properties of Crosslinked Polyethylene Foam:

XLPE is a soft foam that has a smooth surface which has a refined look and feel. This foam is oftentimes used in packaging, and medical applications because of its ability to protect Class A surfaces. To the touch, crosslinked polyethylene can feel very dense. XLPE foam comes in a closed-cell structured configuration. This provides it with the ability to resist almost all water intrusion. Not only does crosslinked polyethylene resist water absorption, it also is lightweight, and extremely buoyant. XLPE foams typically exhibit great performance at a wide range of temperatures as thermal insulation. Crosslinked polyethylene foams also have great ozone resistance. Given all of its great properties, it has a wide range of uses across industries. One thing to note, it is often not applied to any given military specification.

Applications:

The applications that XLPE foams are typically used in may include:

-Packaging

-HVAC

-Cushioning

-Lining in Orthopedics

-Thermal Insulation

-Medical Applications

Availability of Crosslinked Polyethylene Foam:

Crosslinked polyethylene can come in a number of densities ranging from 2 to 8 pcf. Standard PCFs depend on the manufacturer of the products, typically they are provided in 2, 4, 6, or 8. One of the great things about foam materials is that they frequently are available in non-standard thicknesses without much added cost, albeit this is not always the case. While XLPE foam normally comes in its typical creamy white color, it is also available in other colors upon request. Many manufacturers make cross linked polyethylene foam. It now comes in a number of branded products including Volara™, Zotefoams™, Fuzion, Vizion and others.

Lamination of Larger Thicknesses

If the specific thickness is not available, NEDC is oftentimes able to laminate the foam to the thickness required such as 3M 9472LE. We use waterjet cutting to cut extremely thick cross sections of polyethylene foam. Lastly, customers will ask for their foams to have a PSA backing. NEDC can provide foams with acrylic PSA backings. Alternatively, we provide crosslinked polyethylene in foam tapes as well. For more information about XLPE foams or would like your foam converted(die cutting, waterjet cutting) please contact sales@nedc.com.