Electrically Conductive Fluorosilicone Gaskets and Seals – Compound CE-018

The fluorosilicone matrix offers a durable polymer to many fluids. It has survived against hydrocarbons and other aggressive fluids that its silicone counterpart may have trouble sealing against consistently. The fluorosilicone also offers significant sealing at high and low temperatures, similar to that of its silicone counterparts. The temperature stability travels from 160°C to -55°C. Some applications require high conductivity to satisfy certain requirements. Volume resistivity is normally a good indication of how conductive a certain material is. Ni/C has a high volume resistivity but given good surface contact this material can prove to be a formidable competitor with its silver-filled compeers.

Another benefit of nickel graphite elastomers is its ability to “bite” through contact surfaces. This ability is a nod to the hardness of the particles filling the material. The “bite-through” contact can prove beneficial especially when metal surfaces have been plated, i.e., for corrosion resistance. This “bite-through” can further increase surface contact, thus increasing total conductivity. While the volume resistivity of CE-018 is high, reaching values of .100 ohm-cm, it has impressive shielding against E-fields giving attenuations of 100dBs at 100Mhz, and 500Mhz. CE-018 also features high shielding values in the presence of magnetic fields, giving up to 55 dBs at 50 KHz. Finally, it features 100dBs of attenuation at 10Ghz of planewave.

In addition to this material’s impressive shielding performance, it also features ozone resistance and a long shelf life. One of the most concerning parts of a material is its ability to be resilient in the face of environments conducive to galvanic corrosion. Our nickel-graphite fluorosilicone is extremely resilient to galvanic corrosion. Its ability to resist galvanic corrosion is amplified through low permeability of fluorosilicone. While offering similar performance to its MIL-DTL-83528 companions, Ni/C elastomers are not listed in the military specification. It is worth noting that the elastomers are tested via the same test methods outlined in the MIL-DTL-83528.

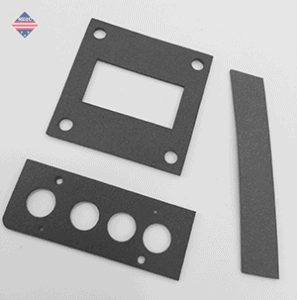

Our nickel-coated graphite fluorosilicone comes in a variety of forms, including die-cuts, waterjet-cuts, sheets, cord-stock, and molded parts. The inherent color of the material is a dark grey. This material is also available with electrically conductive PSA backing. For more information regarding our nickel-graphite fluorosilicone please contact sales@nedc.com.